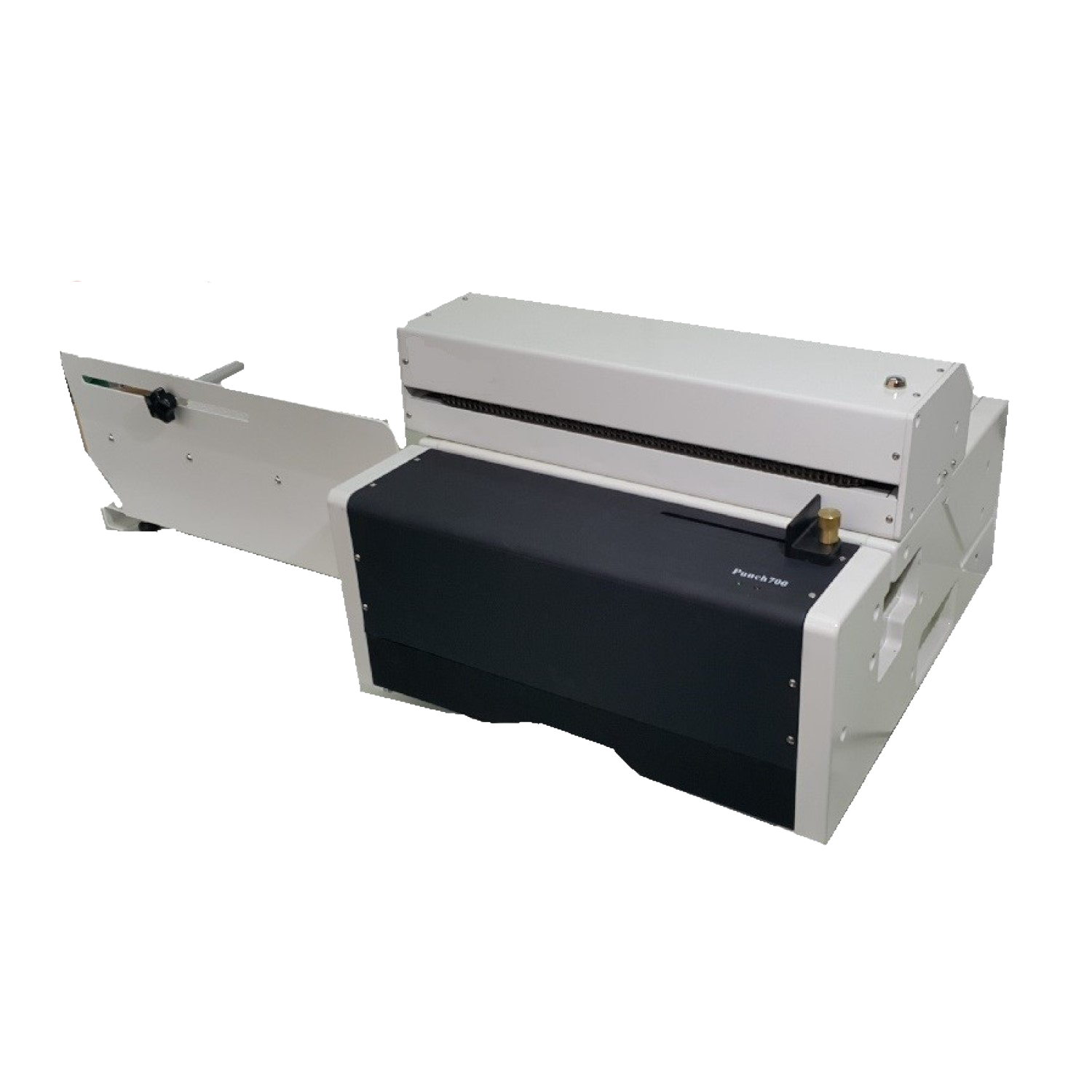

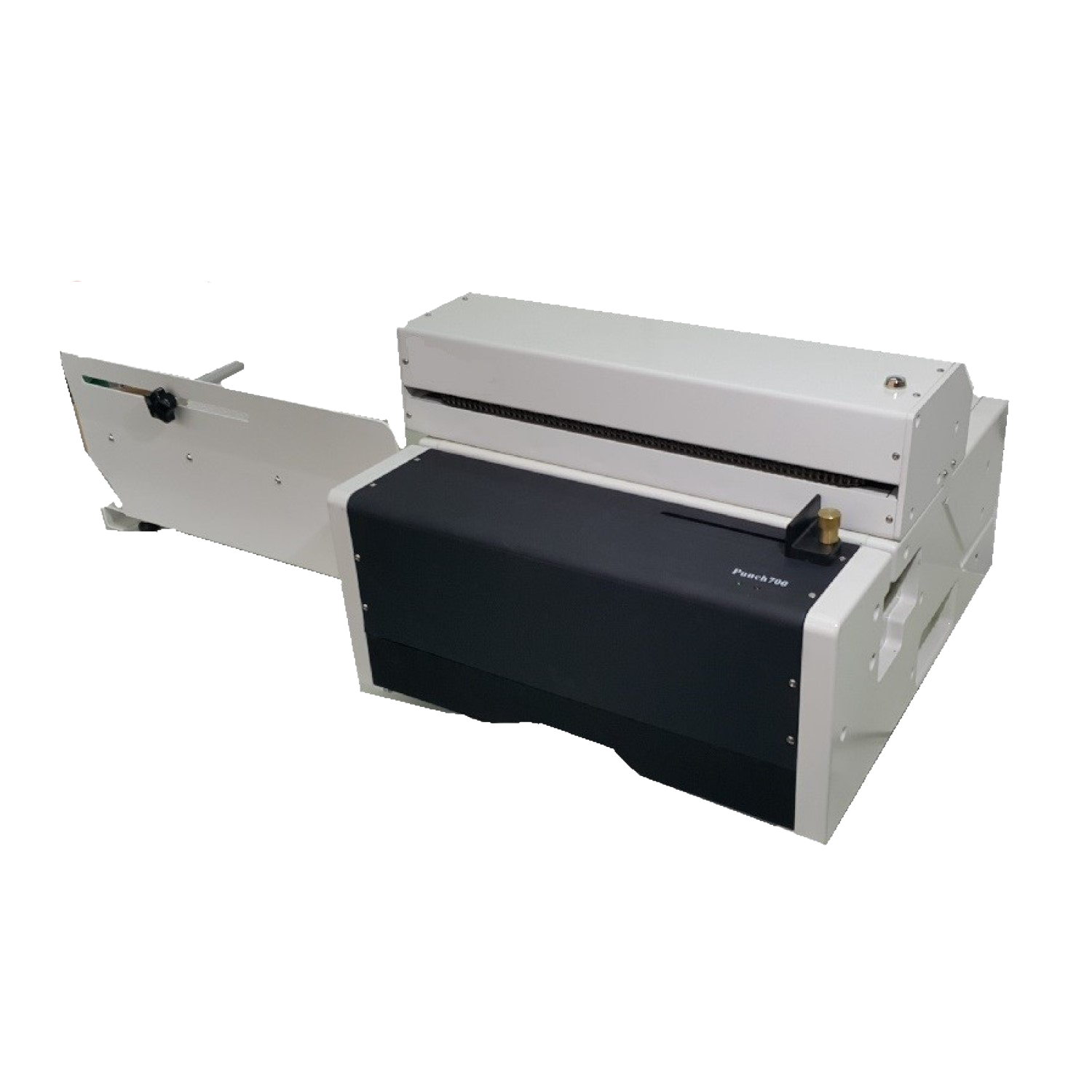

Okoboji Wiro Binder Electric Punch 700

SPECIFICATIONS

PRODUCT VIDEO

PRODUCT DESCRIPTION

The Okoboji Wiro Binder Electric Punch 700 stands as the pinnacle of heavy-duty binding technology, engineered specifically for high-volume operations in demanding Indian commercial environments. This industrial-strength machine represents a quantum leap in binding efficiency, capable of processing up to 24,000 sheets per hour under optimal operating conditions, making it the ideal solution for printing houses, large corporations, educational institutions, and government offices requiring exceptional throughput capacity.

The Punch 700’s robust 400W motor delivers consistent power that effortlessly handles the most challenging binding tasks, from thick cardstock presentations to multi-layer laminated documents. This machine addresses the critical need in India’s rapidly expanding business sector for reliable, high-capacity binding equipment that maintains precision whilst delivering the volume output essential for meeting tight deadlines and customer demands. The advanced electrical systems ensure consistent performance even during extended operational periods.

The dual-component design philosophy maximises operational flexibility by separating punching and wire-closing functions, allowing simultaneous operation by multiple staff members and significantly increasing overall productivity. This thoughtful engineering approach reflects Okoboji’s deep understanding of Indian workplace dynamics and the need for equipment that enhances rather than constrains operational efficiency.

Upgrade Your Experience

Okoboji Binder Comb C20

Okoboji Wiro & Spiral Binder SW2500

Okoboji Wiro Binder Electric DW600

Okoboji Wiro Binder W20 A4

KEY FEATURES

- Exceptional 40-sheet punching capacity with 4.0mm thickness handling capability dramatically increases productivity for high-volume binding operations in demanding commercial environments.

- Powerful 400W motor ensures consistent performance during extended operation whilst maintaining precision and reliability under continuous heavy-duty usage conditions.

- High-speed 1-second punching cycle enables processing up to 24,000 sheets per hour, making it ideal for time-sensitive projects and large-scale document production.

- F4 paper format compatibility accommodates standard Indian business document sizes whilst providing flexibility for various international paper formats.

- Dual voltage compatibility (110V/240V, 60/50Hz) ensures seamless integration into diverse Indian electrical infrastructure and international operational requirements.

- Adjustable margin control (2.5-6.5mm) provides precise customisation for different document types and professional presentation standards across various industries.

- Modular design with separate components optimises workspace organisation and allows simultaneous operation by multiple operators for enhanced productivity.

- Interchangeable die sets (optional) expand versatility for specialised binding requirements and future operational expansion without equipment replacement.

FREQUENTLY ASKED QUESTIONS

What distinguishes the Punch 700 from standard wiro binding machines available in India?

The Punch 700 features industrial-grade 400W motor, 40-sheet capacity, 1-second cycle time, and modular design specifically engineered for high-volume commercial operations exceeding 10,000 sheets daily.

How does the 24,000 sheets per hour capacity translate to real-world productivity gains?

This capacity enables processing large projects like annual reports, catalogues, and training materials within tight deadlines, reducing labour costs and allowing businesses to accept larger contracts confidently.

What electrical requirements must be met for optimal Punch 700 performance?

The machine requires stable 400W power supply with proper grounding, surge protection, and dedicated circuit to prevent voltage fluctuations that could affect precision and motor longevity.

Can the Punch 700 handle specialised materials like PVC, cardstock, and laminated covers?

Yes, the robust motor and precision engineering accommodate materials up to 4.0mm thickness, including heavy cardstock, laminated covers, PVC sheets, and multi-layer documents effectively.

What training requirements ensure operators maximise the Punch 700's capabilities safely?

Okoboji provides comprehensive operator training covering safety protocols, maintenance procedures, troubleshooting techniques, and efficiency optimisation to ensure maximum return on investment and safe operation.

How do interchangeable die sets expand the machine's versatility for different applications?

Optional die sets accommodate various hole patterns, wire sizes, and speciality binding requirements, allowing adaptation for calendars, notebooks, technical manuals, and custom binding applications.

What maintenance schedule ensures optimal performance and prevents costly downtime?

Daily cleaning of punch waste, weekly lubrication of moving parts, monthly inspection of cutting dies, and quarterly professional servicing maintain peak performance and extend equipment lifespan.

Does the modular design provide advantages for workspace organisation and efficiency?

The separate punching and closing components allow flexible workspace arrangement, simultaneous operation by multiple staff, and easier maintenance access compared to integrated binding machines.

What cost savings can businesses expect from investing in the Okoboji Punch 700?

Reduced labour costs, increased throughput capacity, improved binding quality, and enhanced customer satisfaction typically provide return on investment within 12-18 months for high-volume operations.

How does Okoboji support Punch 700 users with technical assistance and parts availability?

Comprehensive support includes 24/7 technical helpline, nationwide service network, guaranteed spare parts availability, and field service technicians for prompt resolution of operational issues.

Customers also bought

Okoboji Glue Binding Machine B40F

Okoboji Paper Creaser Automatic 13" 330mm ACM13

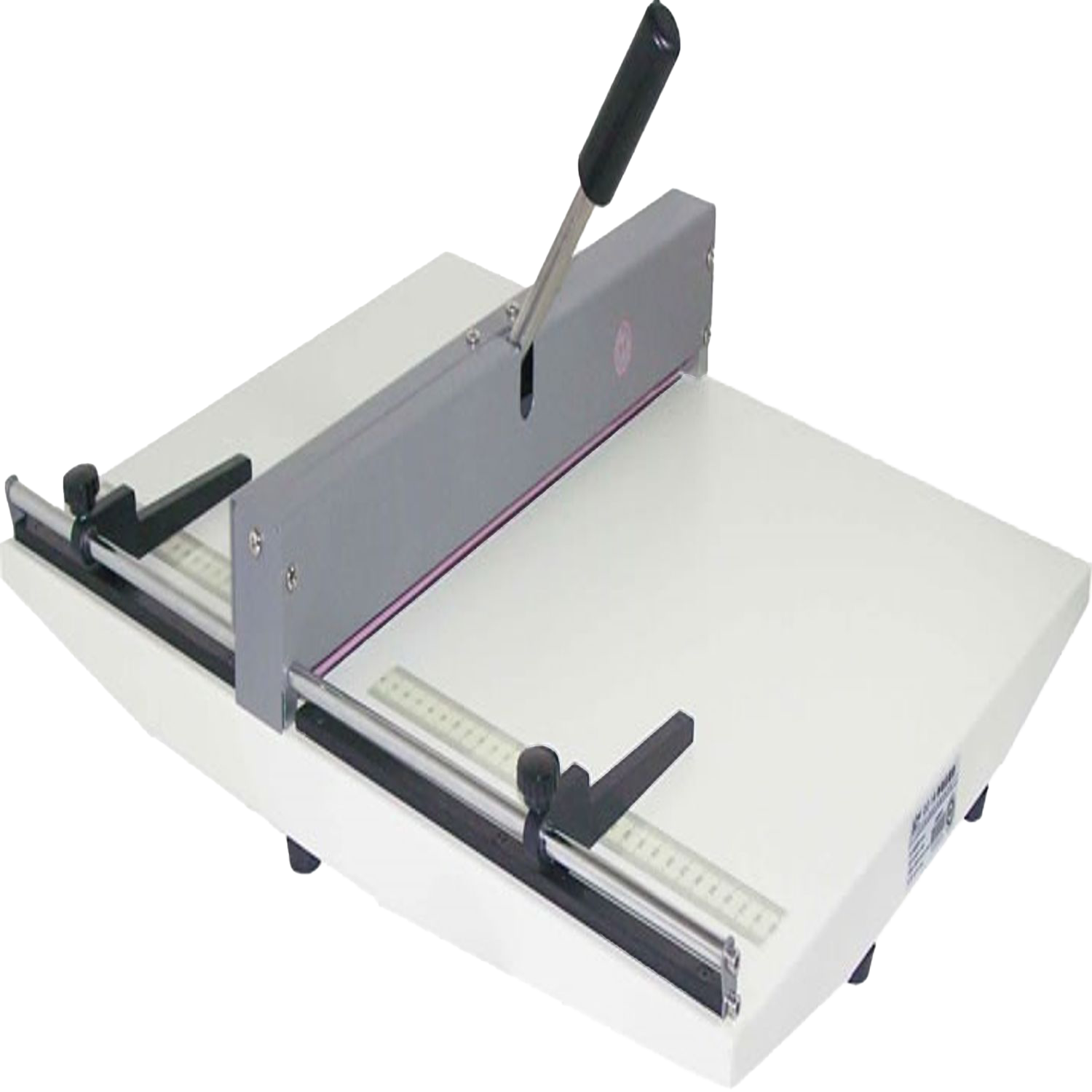

Okoboji Paper Creaser Manual A3 Size H460