Okoboji PVC Card Cutter 8251

SPECIFICATIONS

PRODUCT VIDEO

PRODUCT DESCRIPTION

Okoboji’s PVC Card Cutter 8251 delivers precision manual card cutting capabilities for small to medium-sized businesses across India requiring reliable, cost-effective card production solutions. This robust manual cutting machine specialises in creating perfectly sized PVC cards with the standard 85.7x54mm dimensions commonly used for identification cards, membership cards, business cards, and access control cards throughout Indian organisations. The machine’s manual operation provides complete operator control over cutting precision whilst eliminating electricity costs and operational dependencies, making it ideal for businesses prioritising operational flexibility and cost efficiency.

The cutter accommodates various PVC thicknesses from 0.1mm to 1.2mm, enabling versatile application across different card materials and security requirements preferred by Indian businesses. The inlet dimension of 105x297mm allows efficient loading of pre-printed PVC sheets, streamlining the card production workflow for printing services, educational institutions, and corporate environments. Okoboji’s engineering ensures consistent cutting quality through precision-manufactured cutting dies and robust construction that withstands continuous professional use. This machine represents an excellent entry-level investment for businesses beginning card production operations or requiring backup cutting capabilities for their existing equipment.

Upgrade Your Experience

Okoboji ID Card Fusing A4 100

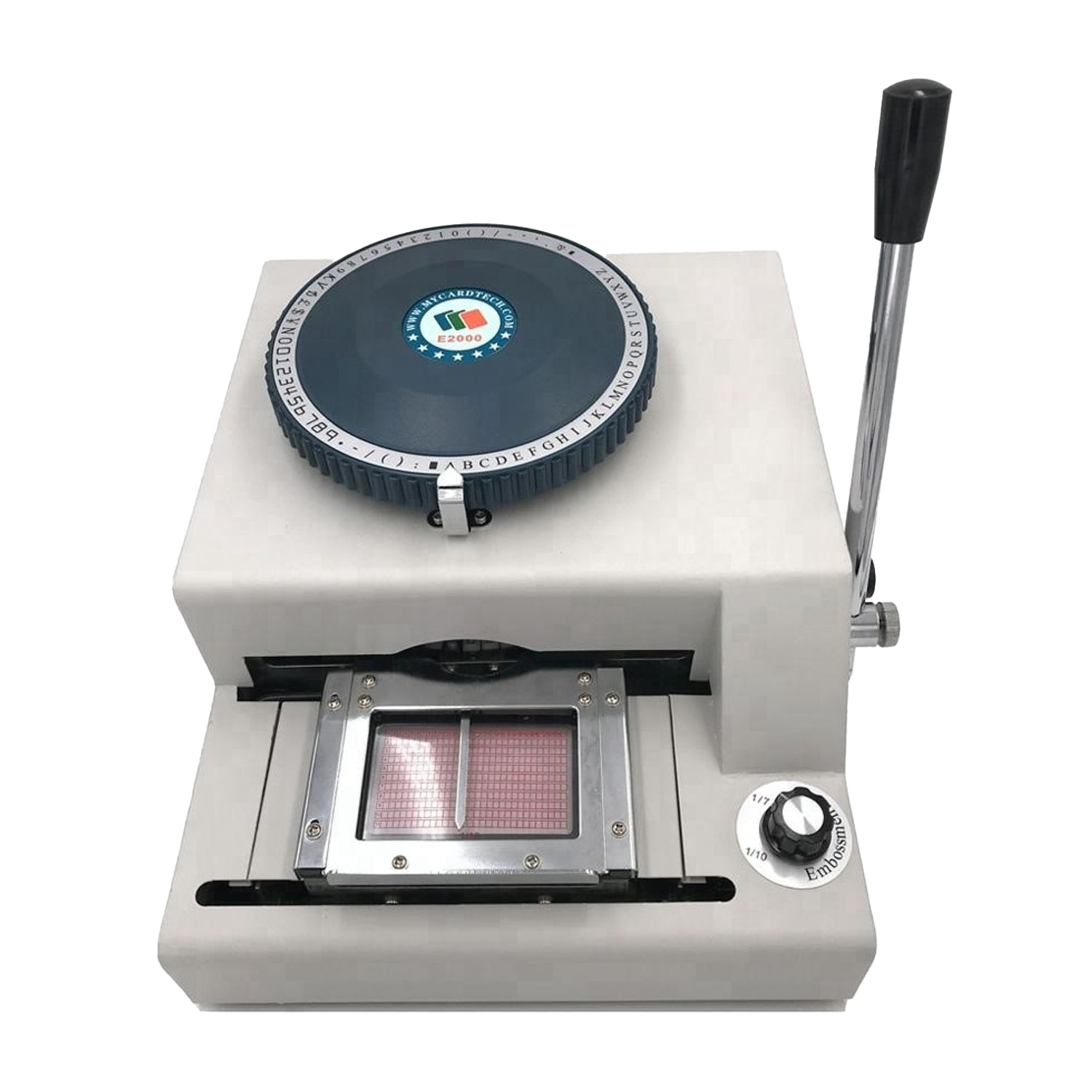

Okoboji ID Card PVC Embossing Machine EM PVC

Okoboji ID Card PVC Foil Tipper WTJ90A

Okoboji PVC Card Cutter Yatai 86YT

KEY FEATURES

- Manual operation provides complete cutting control without electricity requirements, ensuring operational independence and cost-effective card production for Indian small businesses

- Standard 85.7x54mm cutting size produces ISO-compliant cards suitable for identification, membership, access control, and business card applications across diverse industries

- Versatile thickness accommodation (0.1-1.2mm) handles various PVC materials from standard cards to premium thick cards preferred by Indian organisations

- Efficient 105x297mm inlet dimension enables streamlined loading of pre-printed sheets, optimising workflow productivity for printing services and corporate card production

- Precision cutting dies ensure clean edges and professional finish quality meeting the standards expected by Indian banks, educational institutions, and government organisations

- Robust construction guarantees reliable performance under continuous use, making it suitable for both occasional card production and regular commercial operations

- Cost-effective manual design eliminates ongoing electricity expenses whilst providing professional cutting results comparable to more expensive automated equipment

- Okoboji's proven reliability and comprehensive support network ensure dependable operation and readily available technical assistance for card cutting applications across India

FREQUENTLY ASKED QUESTIONS

What types of cards can be cut using the Okoboji 8251 manual PVC card cutter?

This cutter produces standard ID cards, employee badges, membership cards, student cards, access control cards, loyalty cards, and business cards meeting ISO CR80 specifications used across Indian organisations.

How does manual operation benefit small businesses compared to electric card cutters?

Manual operation eliminates electricity costs, provides complete cutting control, ensures operational independence during power outages, reduces maintenance requirements, and offers cost-effective entry into professional card production.

What PVC materials and thicknesses are compatible with this cutting machine?

The machine cuts standard PVC sheets, premium card materials, laminated cards, and overlay films with thicknesses ranging from 0.1mm to 1.2mm commonly used in Indian card production.

Is training required for operators to achieve consistent cutting results with this equipment?

Basic training covers proper material positioning, cutting technique, safety procedures, and quality control measures. Okoboji provides comprehensive operation manuals and technical support for new operators.

How does the 105x297mm inlet dimension improve card production efficiency?

This dimension accommodates standard A4-sized sheets with multiple card layouts, enabling efficient batch cutting and reducing material waste whilst optimising production workflow for printing services.

What maintenance procedures ensure optimal cutting performance and blade longevity?

Regular blade inspection, cutting die cleaning, lubrication of moving parts, and proper storage maintain optimal performance. Okoboji provides detailed maintenance guidelines for extended equipment lifespan.

Can this machine handle different card layouts and cutting patterns beyond standard sizes?

The machine is optimised for standard 85.7x54mm cards, but experienced operators can adapt cutting techniques for various layouts whilst maintaining cutting quality and safety standards.

What safety features and precautions are essential when operating manual card cutters?

Proper hand positioning, cutting die protection, material securing techniques, and adherence to Okoboji's safety guidelines prevent accidents and ensure safe operation in professional environments.

How does this manual cutter compare to electric models in terms of cutting precision?

Manual operation allows precise control over cutting pressure and timing, often achieving superior edge quality for specialised applications whilst providing cost-effective solutions for smaller production volumes.

What technical support does Okoboji provide for manual card cutter operation and troubleshooting?

Okoboji offers telephone support, operation training materials, replacement parts availability, maintenance guidelines, and regional service networks ensuring reliable card cutting operations across India.

Customers also bought

Okoboji Glue Binding Machine B40M

Okoboji Perfect Binder A3 Side Glue

Okoboji Sublimation Heat Press Dual Station Pneumatic