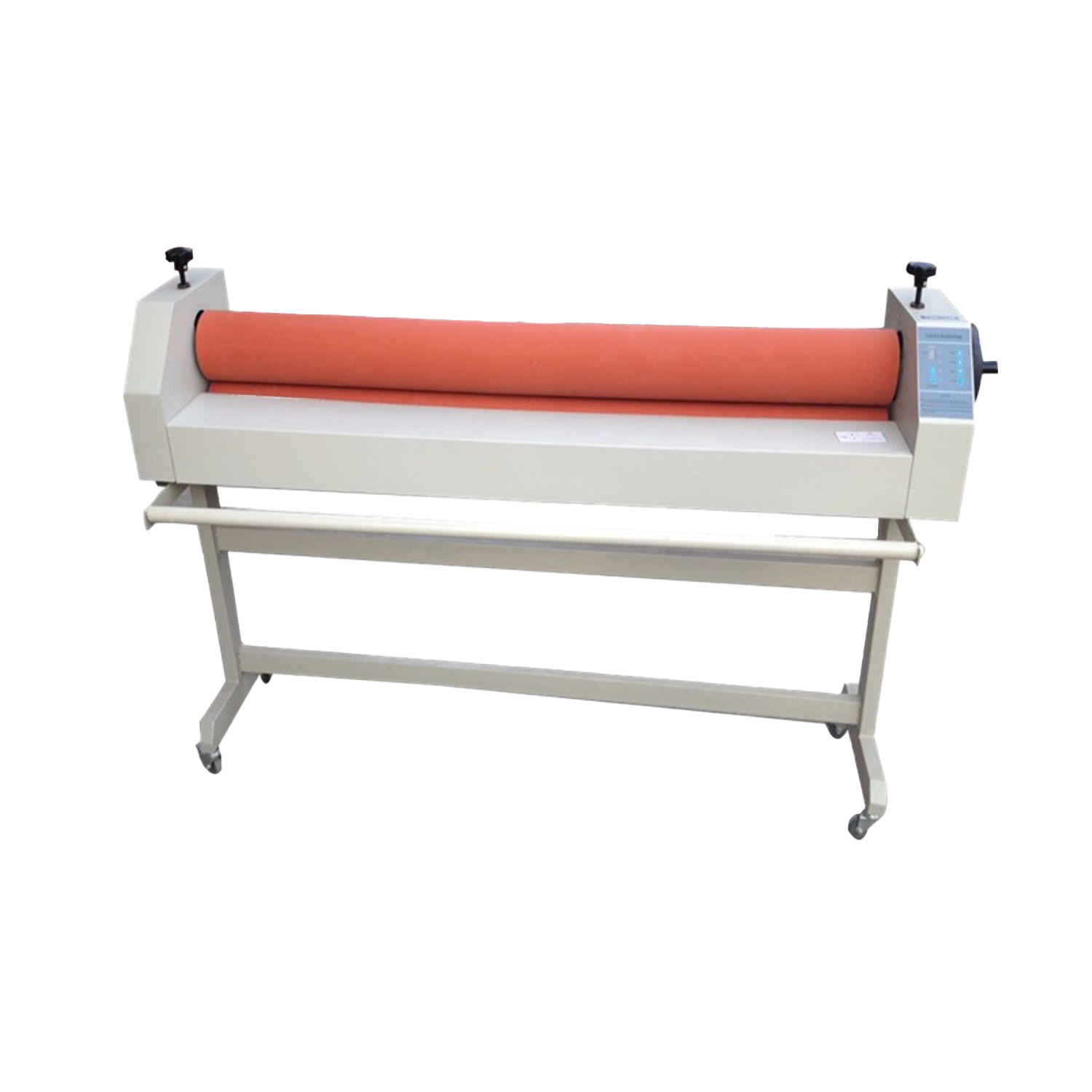

Okoboji Cold Laminator Electric 650mm

SPECIFICATIONS

PRODUCT VIDEO

PRODUCT DESCRIPTION

The Okoboji Cold Laminator Electric 650mm 650E offers the perfect balance of automated efficiency and manual control flexibility, designed specifically for busy offices, educational institutions, and small to medium print shops throughout India. This innovative dual-operation machine provides both electric and manual laminating modes, allowing operators to choose the most appropriate method for different materials and applications. The 650mm working width accommodates A2 documents, photographs, certificates, and most standard business materials, whilst the 5mm thickness capacity handles everything from delicate papers to mounting boards and presentation materials.

Featuring intelligent design that combines the speed and consistency of electric operation with the precision control of manual mode, this Okoboji laminator adapts to varying workload demands and material requirements throughout the day. The electric mode delivers rapid, consistent processing for high-volume jobs, whilst manual mode provides careful control for delicate materials, specialty films, or precision applications. Whether protecting important certificates, creating durable signage, or processing daily document laminating requirements, this versatile machine provides the operational flexibility and reliable performance that modern Indian businesses require for their diverse laminating needs.

Upgrade Your Experience

Okoboji Cold & Thermal Laminator L1700T1

Okoboji Cold Laminator Elec Pneumatic 63" 1600mm

Okoboji Cold Laminator Electric 63" 1600 mm

Okoboji Cold Laminator Manual 40" 1000 mm

KEY FEATURES

- Dual operation modes - Electric and manual operation options provide flexibility for different materials, volumes, and precision requirements

- Optimal 650mm working width - Accommodates A2 documents, oversized photographs, certificates, and multiple A4 materials simultaneously for versatile applications

- 5mm thickness accommodation - Handles diverse materials from delicate photographs to mounting boards and thick presentation materials with appropriate pressure control

- Electric mode efficiency - Automated operation increases productivity for high-volume jobs whilst maintaining consistent quality and reducing operator fatigue

- Manual mode precision - Provides careful control for delicate materials, specialty applications, and situations requiring precise pressure and speed adjustment

- Compact professional design - Okoboji's space-efficient construction fits comfortably in offices, schools, and workshops without overwhelming available workspace

- Versatile material compatibility - Processes various cold laminating films, pressure-sensitive adhesives, and protective materials for comprehensive document protection applications

- Reliable dual-mode performance - Robust construction ensures consistent operation in both electric and manual modes for long-term productivity and value

FREQUENTLY ASKED QUESTIONS

When should I use electric versus manual mode on this Okoboji laminator?

Use electric mode for consistent, high-volume processing of standard materials. Choose manual mode for delicate photographs, specialty films, thick materials, or when precise speed and pressure control is required for optimal results.

What materials work best with the 650mm width and 5mm thickness capacity?

Perfect for A2 documents, certificates, photographs, ID cards, maps, charts, presentation covers, lightweight mounting boards, and multiple A4 documents. The 5mm capacity handles most office and educational materials effectively.

How does dual-mode operation benefit busy office environments?

Dual modes provide operational flexibility throughout the day. Process routine documents quickly in electric mode, then switch to manual mode for special projects, delicate materials, or when precise control is needed without requiring separate machines.

Can this machine handle both standard and specialty laminating films?

Yes, the dual-mode design accommodates standard pressure-sensitive films, matte and gloss options, anti-glare films, and specialty protective materials. Manual mode provides precise control for handling sensitive or specialty films effectively.

What's the productivity difference between electric and manual modes?

Electric mode significantly increases processing speed for routine jobs, whilst manual mode allows careful handling of special materials. The combination provides optimal productivity whilst maintaining quality for diverse applications throughout the workday.

How do I maintain this dual-mode Okoboji laminator properly?

Clean rollers regularly, check electric motor components, ensure smooth manual operation, and maintain proper lubrication. The dual-mode design requires attention to both mechanical and electrical components for optimal performance.

Is this machine suitable for educational institutions with varying needs?

Absolutely, schools and training centres benefit from the flexibility of processing student certificates in electric mode whilst handling delicate historical documents or special projects in manual mode, providing comprehensive laminating capability.

How does the 650mm width compare to smaller desktop laminators?

The 650mm width significantly exceeds A3 capacity, allowing processing of larger documents, multiple items simultaneously, and materials that smaller units cannot handle, providing excellent versatility for diverse applications.

What power requirements does the electric mode have?

The electric operation requires standard electrical supply for motor operation. Okoboji provides detailed electrical specifications for proper installation. Manual mode operates independently of electrical supply for complete flexibility.

Does Okoboji provide training for both operation modes?

Yes, Okoboji offers comprehensive training covering both electric and manual operation modes, maintenance procedures, troubleshooting, and optimal material handling techniques to ensure maximum productivity and equipment longevity across India.

Customers also bought

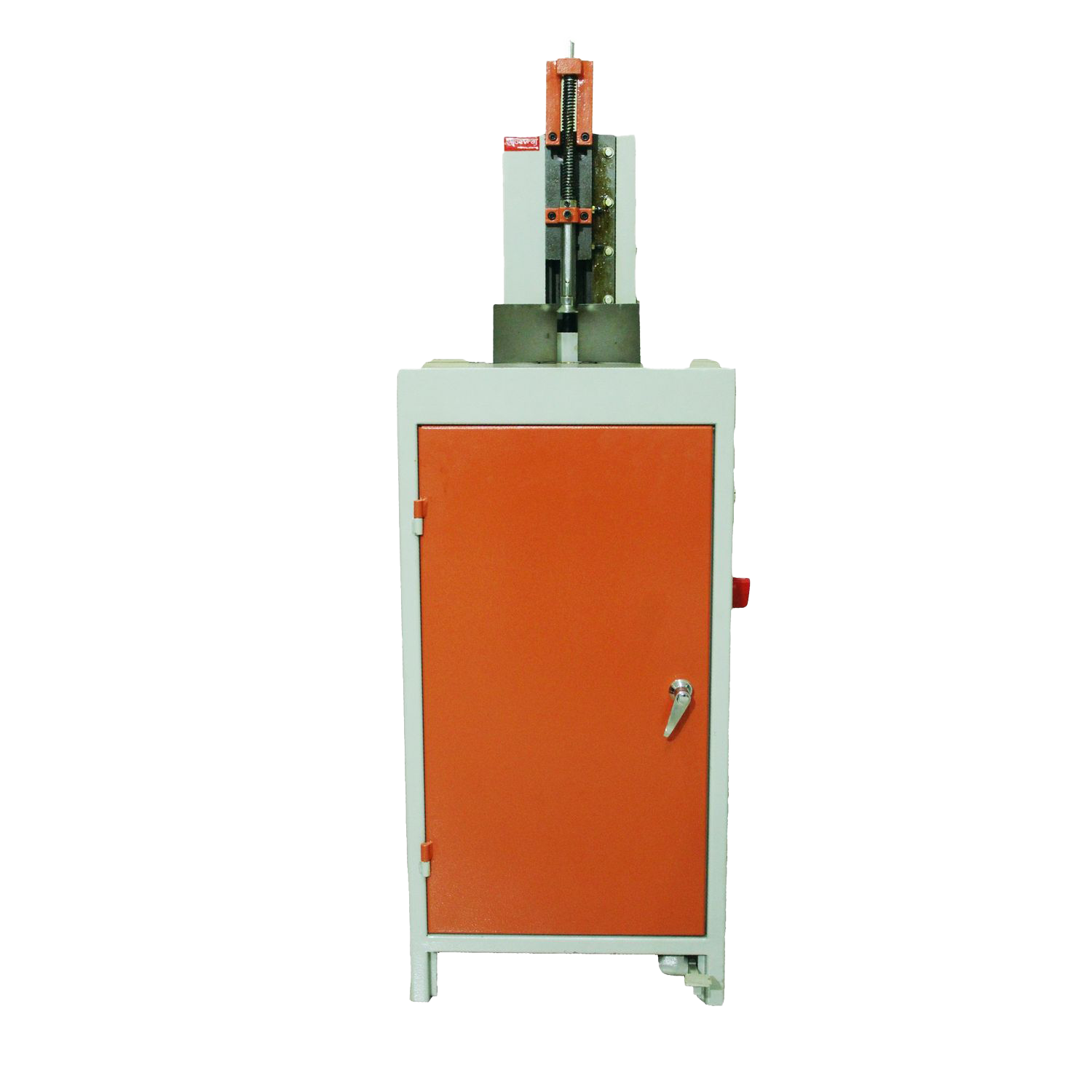

Okoboji Corner Cutter Electric Heavy Duty Orange

Okoboji Corner Cutter Electric Super HD Back Motor Grey

Okoboji Laminator Pouch 320 Knob