Okoboji Badge Slide Mould Round 25mm

SPECIFICATIONS

PRODUCT VIDEO

PRODUCT DESCRIPTION

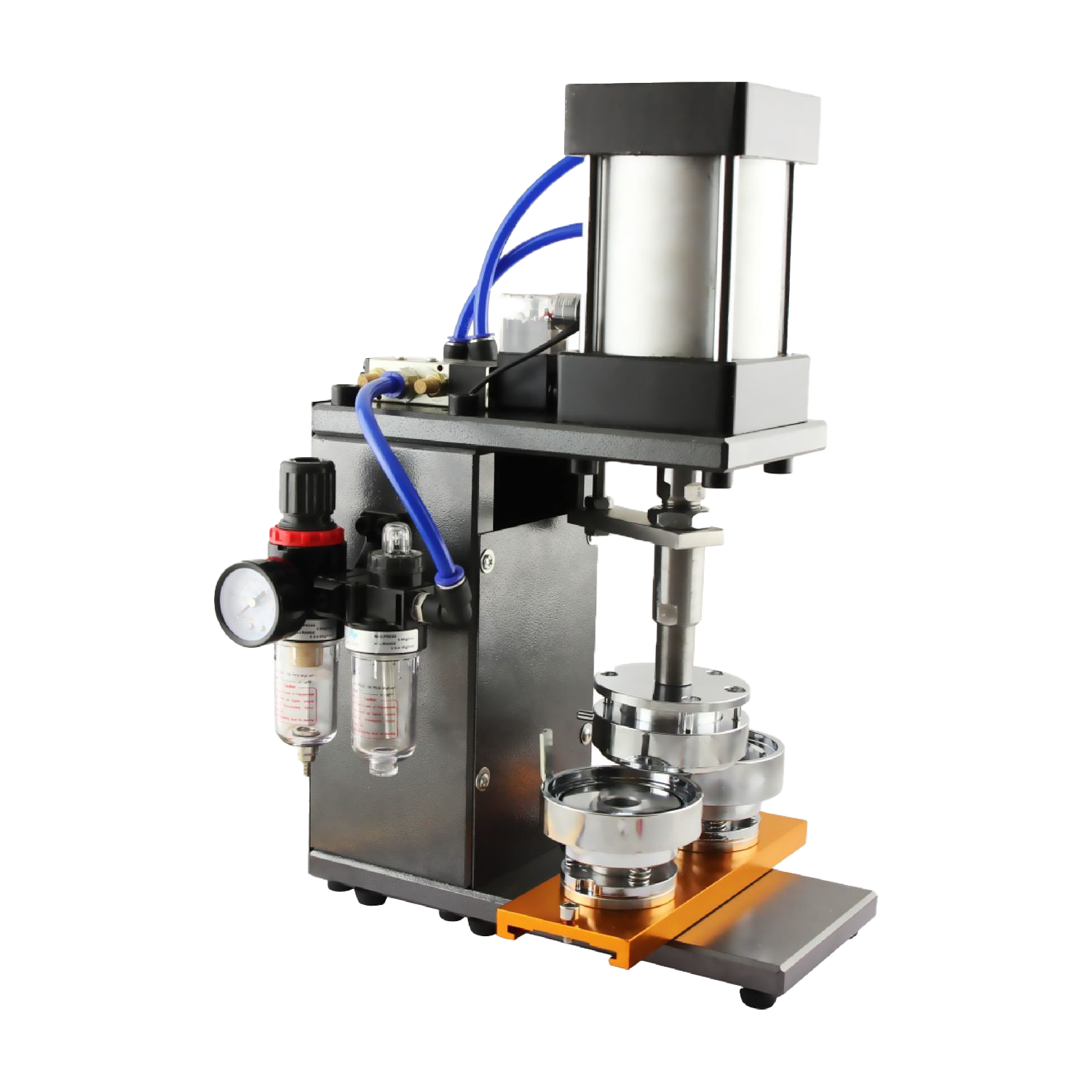

The Okoboji Badge Slide Mould Round 25mm introduces precision compact badge manufacturing to India’s diverse identification and promotional badge industry, combining the efficiency of small-format production with advanced plastic slide plate technology. This expertly engineered chrome plated steel mould delivers exceptional performance in applications requiring discrete, professional badges that maintain high visual impact whilst remaining subtle and elegant. The 25mm round format creates perfectly proportioned compact badges ideal for minimalist corporate identification, security applications, or promotional items where understated professionalism is paramount.

Specifically designed for compatibility with MA01 and MA03 badge punch machines, this compact mould addresses the growing demand for smaller, more refined badge designs in India’s professional markets. The innovative plastic slide plate system enables fast track operation with smooth changeovers, ensuring efficient production workflows even with smaller components. Whether producing discrete employee identification badges, security access credentials, membership badges, or elegant promotional items, this professional-grade mould delivers consistently excellent results that demonstrate Okoboji’s commitment to precision engineering and customer satisfaction across all badge size requirements.

Upgrade Your Experience

Okoboji Badge Magentic Mould Oval 39x31mm

Okoboji Badge Magentic Mould Round 44mm

Okoboji Badge Magentic Mould Square 55x55mm

Okoboji Die Cutter for Badge Round 25mm

Okoboji Die Cutter for Badge Square 35x35mm

Okoboji Punch for Badge Magnetic MA05

Okoboji Punch for Badge Pneumatic MAQ

Okoboji Punch for Badge Slide MA01

KEY FEATURES

- Compact 25mm round format creates discrete, professional badges perfect for minimalist corporate identification and security applications.

- Premium chrome plated steel construction ensures exceptional durability and maintains pristine appearance throughout intensive commercial production environments.

- Advanced plastic slide plate system enables fast track operation with smooth, precise mould changes that optimise production efficiency significantly.

- Precision engineering guarantees perfect small round badge formation with consistent dimensions and professional finish quality throughout extended production runs.

- Universal compatibility with MA01 and MA03 badge punch machines provides maximum production flexibility and optimal equipment utilisation for diverse operations.

- Okoboji's proven manufacturing excellence delivers reliable, high-performance tooling that gives Indian badge producers competitive advantages in specialised markets.

- Innovative slide track technology ensures smooth operation with small components, reducing handling challenges and improving production consistency.

- Professional-grade construction supports high-volume commercial badge production with quality standards that meet demanding corporate client requirements.

FREQUENTLY ASKED QUESTIONS

What advantages does the compact 25mm size offer for specific badge applications?

The small format provides discrete identification perfect for security badges, membership cards, minimalist corporate identification, and applications requiring subtle, professional appearance.

How does the plastic slide plate system benefit small badge production operations?

The smooth slide operation provides precise control essential for small components, ensuring accurate positioning and consistent quality throughout compact badge production.

What design considerations work best with the compact 25mm round format?

Simple logos, clear typography, minimalist designs, and focused messaging work exceptionally well with the compact format, creating elegant, professional badges.

Can this Okoboji slide mould maintain precision during high-volume small badge production?

Yes, the precision-engineered construction and refined slide system ensure consistent badge formation with uniform dimensions throughout demanding commercial production requirements.

What badge materials are most suitable for this compact slide mould system?

The mould works excellently with high-quality papers, security laminates, thin plastic films, and protective coatings optimised for small-format badge applications.

How does the slide track operation ensure accuracy during small badge manufacturing?

The precision-machined slide track provides exact positioning crucial for small badges where dimensional accuracy and alignment are particularly critical for professional appearance.

What maintenance procedures ensure optimal performance of this compact slide mould?

Regular cleaning of slide tracks, careful lubrication of precision components, and periodic inspection of small parts will ensure optimal performance and extended service life.

Does Okoboji provide specialised guidance for optimising small badge production workflows?

Okoboji offers technical support including design recommendations, production guidance, and operational tips specifically for compact badge manufacturing applications.

How does this compact slide mould compare to larger alternatives for efficiency and cost-effectiveness?

Compact moulds offer faster cycle times, reduced material waste, and efficient production particularly advantageous for high-volume small badge applications.

What quality control measures ensure consistent small badge production with this compact mould?

Strict manufacturing tolerances, precision machining processes, and specialised testing protocols guarantee reliable small badge formation and professional results consistently.

Customers also bought

Okoboji Binder Comb C20

Okoboji Handheld Corner Cutter All in One CC085

Okoboji Handheld Slot Punch A112