Okoboji Badge Magentic Mould Oval 39x31mm

Offers

EMI Offer

5% emi uifhddkjnf kN FknaklfnlKMNFLK:mflkmlkmlkMFlkmlkvmlkmvlkmlKVmlkmvlkmlvklkvmlkvmflkv

SPECIFICATIONS

PRODUCT VIDEO

PRODUCT DESCRIPTION

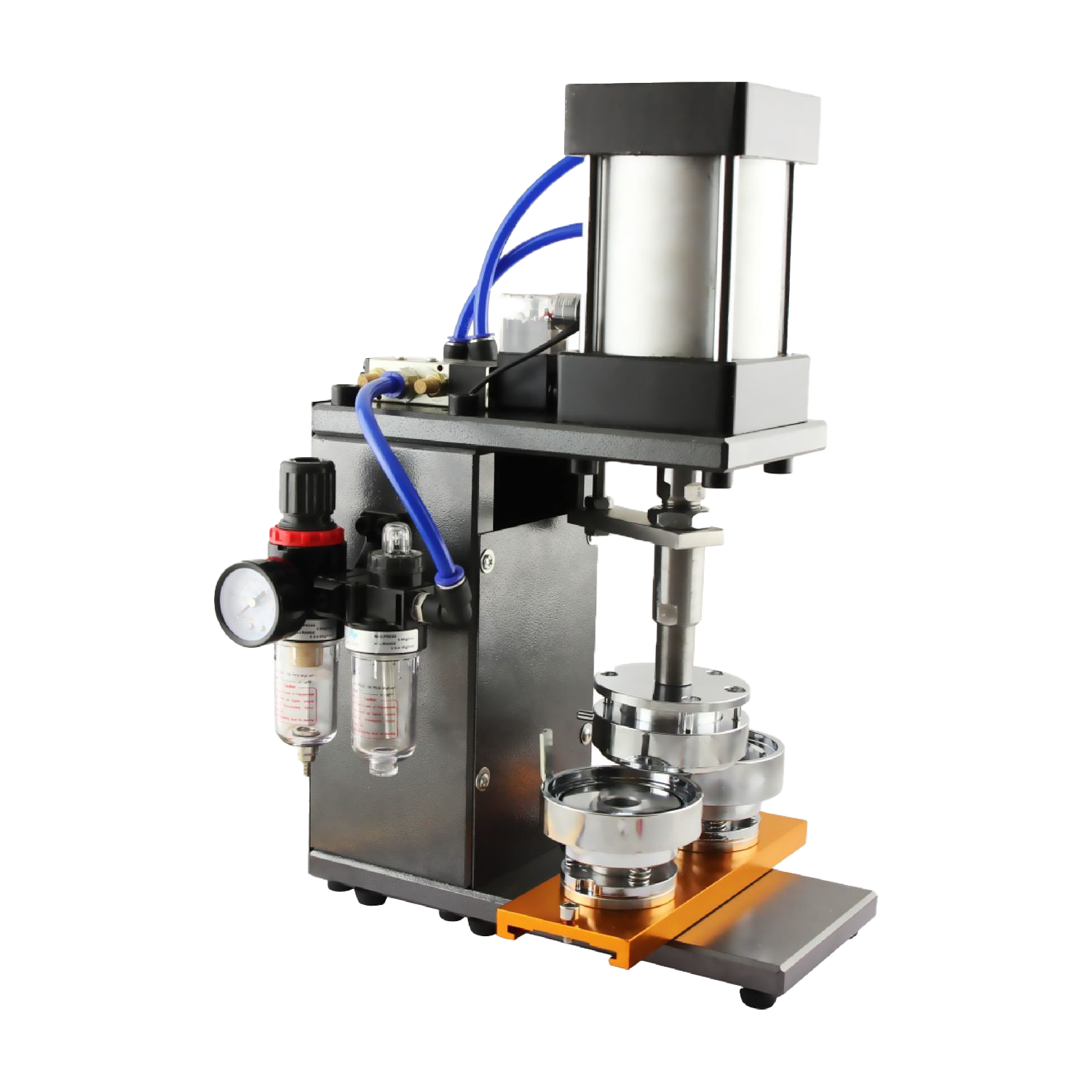

The Badge Magnetic Mould Oval 39x31mm represents a precision-engineered solution for professional badge manufacturing in India’s growing promotional products industry. This specialised mould component forms an essential part of badge-making machinery, enabling businesses to create distinctive oval-shaped badges measuring 39mm by 31mm with consistent quality and professional finish. The magnetic design facilitates rapid mould changes during production runs, significantly improving operational efficiency compared to traditional slide-based systems.

Manufactured from premium chrome-plated steel, this magnetic mould delivers exceptional durability and corrosion resistance essential for high-volume badge production environments. The chrome plating provides a smooth, non-stick surface that ensures clean badge release while maintaining dimensional accuracy across thousands of production cycles. Indian manufacturers, promotional product companies, corporate gift suppliers, and printing businesses will find this mould invaluable for producing corporate identity badges, event credentials, promotional merchandise, and custom-branded items that meet international quality standards whilst serving the specific requirements of the domestic market.

Upgrade Your Experience

Okoboji Badge Magentic Mould Square 35x35mm

Okoboji Badge Slide Mould Round 37mm

Okoboji Die Cutter for Badge Oval 57x45mm

Okoboji Die Cutter for Badge Round 37mm

Okoboji Die Cutter for Badge Square 55x55mm

Okoboji Punch for Badge Magnetic MA05

Okoboji Punch for Badge Pneumatic MAQ

Okoboji Punch for Badge Slide MA01

KEY FEATURES

- PVC Die Card Cutter Machine Model : Badge Square 35 35mm

- Size : 35*35mm

- Cut : 0.1-1mm

- Application : Steel Body + Manganese Steel Blade

- Material Compatibility : PVC Cards, Paper, Cardstock

- Operation Type : Manual

- Construction : Steel Body

- Blade Material : Manganese Steel

- Cutting Range : 0.1-1mm Thickness

- Format : Square Shape

FREQUENTLY ASKED QUESTIONS

What badge machines are compatible with this 39x31mm oval magnetic mould?

This Okoboji magnetic mould is specifically designed for compatibility with MA05, MA02, and MAQ badge making machines, ensuring seamless integration with your existing equipment.

How quickly can I change between different badge moulds during production?

The magnetic fastening system enables lightning-fast mould changes in seconds, dramatically improving production efficiency compared to traditional screw-type mountings.

What materials work best with this chrome plated steel mould for badge making?

This mould works excellently with standard badge making materials including paper, plastic films, metal foils, and laminated graphics typically used in Indian badge manufacturing.

How long will this magnetic badge mould last with regular commercial use?

Okoboji's chrome plated steel construction ensures exceptional durability, with many moulds lasting several years even under intensive daily production schedules.

Can this oval shape accommodate both text and logo designs effectively?

The 39x31mm oval dimensions provide excellent space for company logos, employee names, department information, or promotional messages whilst maintaining professional appearance.

What maintenance is required to keep the magnetic mould functioning properly?

Regular cleaning with mild detergent and ensuring magnetic surfaces remain debris-free will maintain optimal performance and extend the mould's operational life.

Does Okoboji provide technical support for badge mould operation and troubleshooting?

Yes, Okoboji offers comprehensive technical support to help customers optimise their badge production processes and resolve any operational challenges.

How does the magnetic system compare to traditional screw-mounted badge moulds?

Magnetic systems offer significantly faster changeover times, reduced operator fatigue, and improved production flexibility compared to traditional mounting methods.

What quality control measures ensure consistent badge production with this mould?

Precision engineering tolerances and high-grade steel construction ensure uniform badge dimensions and consistent quality throughout extended production runs.

Can this mould handle high-volume production requirements for large corporate orders?

Absolutely, the robust construction and efficient magnetic operation make this mould ideal for high-volume badge production in commercial manufacturing environments.

Customers also bought

Okoboji Corner Cutter Electric Raduis upto 20mm 5 Dye Raduis upto 20mm 5 Dye

Okoboji Corner Cutter Electric Super HD Back Motor Grey

Okoboji Wiro Binder W15 A4