Okoboji Paper Cutter Digital Hydraulic 520mm AirBed

SPECIFICATIONS

PRODUCT VIDEO

PRODUCT DESCRIPTION

The Okoboji Digital Hydraulic Paper Cutter 520mm AirBed represents the pinnacle of cutting technology, combining advanced hydraulic operation with innovative AirBed technology and sophisticated touchscreen control systems. This premium cutting machine delivers exceptional performance through revolutionary air cushion technology that enhances material handling whilst maintaining the precision and power of hydraulic operation. The innovative AirBed system transforms traditional cutting processes by providing superior material support and alignment, ensuring consistent professional results across demanding commercial applications.

This state-of-the-art cutting system addresses the most complex requirements of modern printing businesses and commercial operations through intelligent automation and advanced material handling technology. The revolutionary AirBed technology provides uniform material support across the cutting surface, reducing material distortion whilst improving cutting precision and operational efficiency. Whether processing delicate materials, large format printing, or high-volume commercial projects, the Okoboji AirBed hydraulic cutter delivers unparalleled performance that exceeds industry standards whilst maintaining the reliability and durability essential for demanding business environments.

Upgrade Your Experience

Okoboji Paper Cutter Digital Electric 720mm

Okoboji Paper Cutter Digital Hydraulic 490mm

Okoboji Paper Cutter Digital Hydraulic 520mm

Okoboji Paper Cutter Digital Hydraulic 680mm

KEY FEATURES

- Revolutionary AirBed technology provides uniform material support and enhanced cutting precision through advanced air cushion material handling systems.

- Premium touchscreen interface delivers comprehensive operational control and sophisticated cutting parameter customisation for optimal performance across applications.

- Advanced hydraulic operation system combines powerful cutting force with gentle material handling through innovative air cushion technology.

- Enhanced 520mm cutting width with AirBed support accommodates diverse materials whilst maintaining exceptional precision and alignment.

- Professional-grade 380kg construction ensures exceptional stability during hydraulic operations whilst providing robust long-term reliability.

- Okoboji's cutting-edge AirBed engineering delivers superior material handling and precision cutting performance in demanding commercial environments.

- Comprehensive infrared safety protection ensures operator security during powerful hydraulic operations with advanced air cushion systems.

- Sophisticated material support technology reduces handling stress whilst improving cutting quality and operational efficiency significantly.

FREQUENTLY ASKED QUESTIONS

What specific advantages does AirBed technology provide for professional cutting applications?

AirBed technology creates uniform material support through air cushioning, reducing material distortion whilst improving cutting precision and handling efficiency.

How does the air cushion system enhance cutting quality compared to traditional cutting surfaces?

The air cushion provides consistent support across the entire cutting surface, eliminating material sag and ensuring precise cuts across delicate materials.

What types of materials benefit most from Okoboji's AirBed cutting technology?

Delicate papers, thin materials, large format prints, and precision applications requiring minimal material stress achieve superior results with AirBed support.

How does the touchscreen interface integrate with the AirBed system for optimal operation?

The touchscreen controls both hydraulic parameters and air pressure settings, enabling precise customisation for various materials and cutting requirements.

What maintenance requirements apply to the AirBed system and hydraulic components?

Regular air system inspection, hydraulic fluid monitoring, and touchscreen calibration maintain optimal performance with comprehensive maintenance schedules provided.

Can the AirBed pressure be adjusted for different material types and thicknesses?

Yes, the touchscreen interface allows precise air pressure adjustment to accommodate various material types whilst maintaining optimal support and precision.

How does the 450kg construction contribute to stability during AirBed operations?

The substantial weight ensures exceptional stability during hydraulic and air cushion operations, maintaining precise alignment and consistent cutting accuracy.

What safety features protect operators when using this advanced AirBed cutting system?

Comprehensive infrared safety systems, hydraulic pressure monitoring, and air system controls ensure complete operator protection during sophisticated operations.

What technical training does Okoboji provide for this premium AirBed cutting technology?

Advanced training covers AirBed operation, touchscreen controls, hydraulic systems, and optimisation techniques for maximum productivity and precision.

Is this AirBed cutting machine suitable for processing high-value or delicate printing materials?

Yes, the gentle air cushion support and precise hydraulic control make it ideal for valuable materials requiring careful handling and exceptional cutting quality.

Customers also bought

Okoboji Glue Binding Machine B40M

Okoboji Paper Creaser Automatic 13" 330mm ACM13

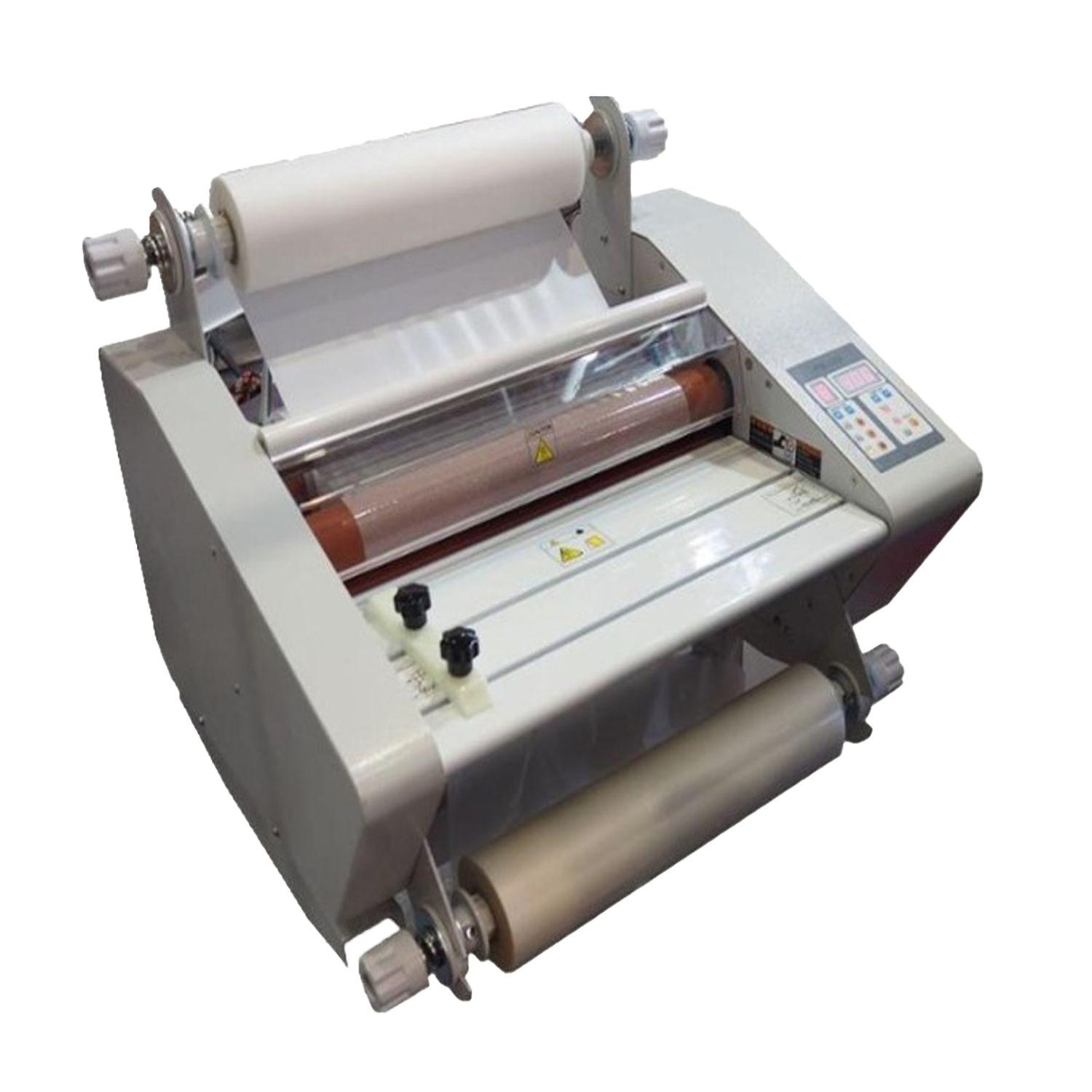

Okoboji Okoboji Thermal Roll Laminator FM360 360mm