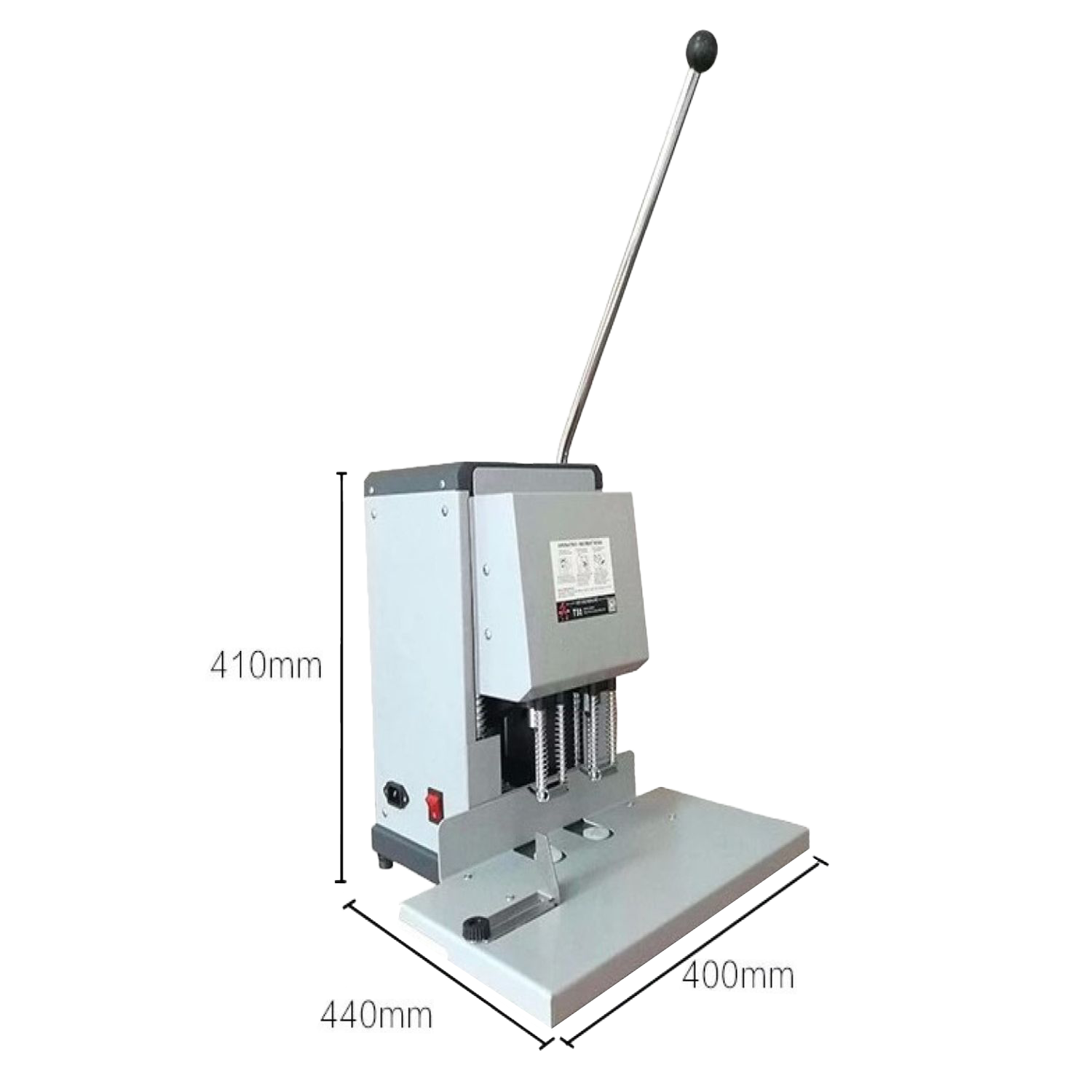

Okoboji Hole Punch Electric Drill 2 Head HD WYT50

SPECIFICATIONS

PRODUCT VIDEO

PRODUCT DESCRIPTION

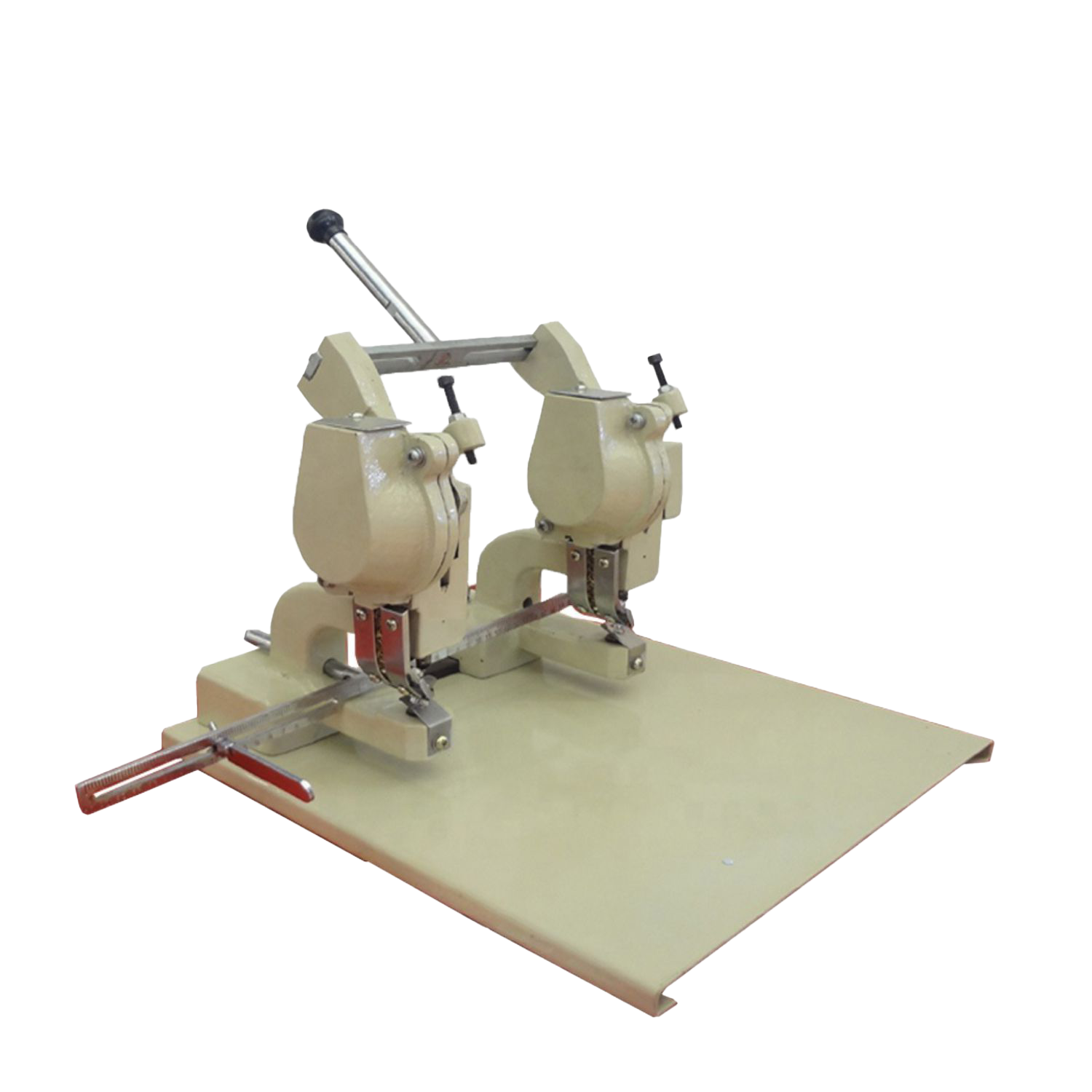

The Okoboji Electric Drill 2 Head HD WYT50 revolutionises high-volume document processing for Indian printing houses, educational institutions, and commercial binding operations. This sophisticated dual-head electric punch machine delivers exceptional productivity with an impressive 500-page punching capacity (50mm total thickness), making it the perfect solution for large-scale document preparation, textbook binding, and commercial printing applications. The precision-engineered dual-head design creates uniform hole spacing of 80mm and 70mm, ensuring consistent results that meet professional binding standards required in educational and commercial environments across India.

Advanced electric operation eliminates the physical strain associated with manual punching while delivering significantly faster processing speeds essential for meeting tight production deadlines. The adjustable hole diameter range of 3-6mm accommodates various binding systems from spiral binding to ring binders, making this versatile machine suitable for diverse applications including course materials, training manuals, and commercial documentation. The generous 400x210mm work plate accommodates various document sizes while the adjustable margin feature (8-35mm) ensures precise hole placement for different paper formats. At 25.5kg, this professional-grade equipment provides the stability and durability required for continuous commercial operation while maintaining the precision standards that educational and commercial customers demand from Okoboji equipment.

Upgrade Your Experience

Okoboji Handheld Punch Single T35

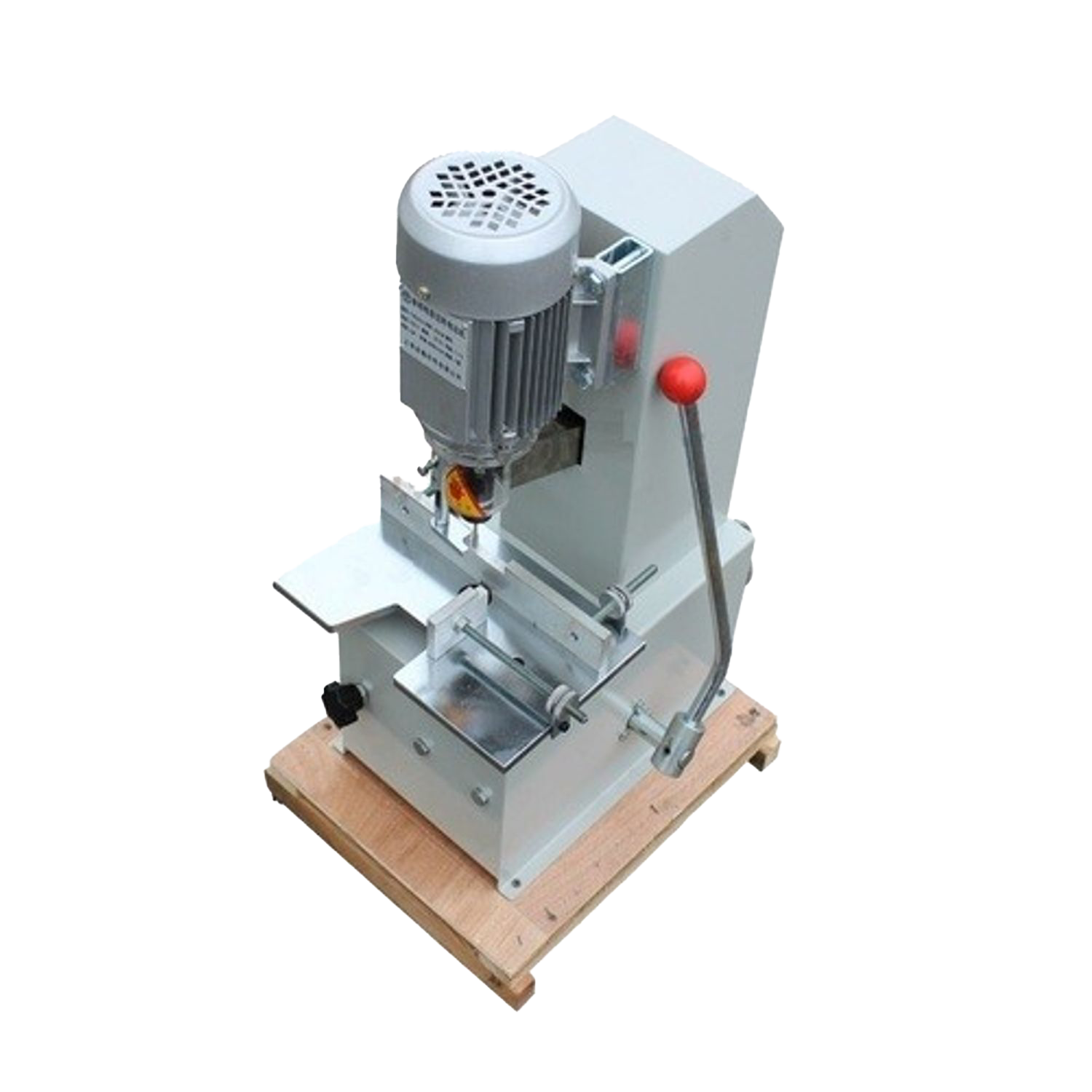

Okoboji Hole Punch Electric Drill 1 Head HD

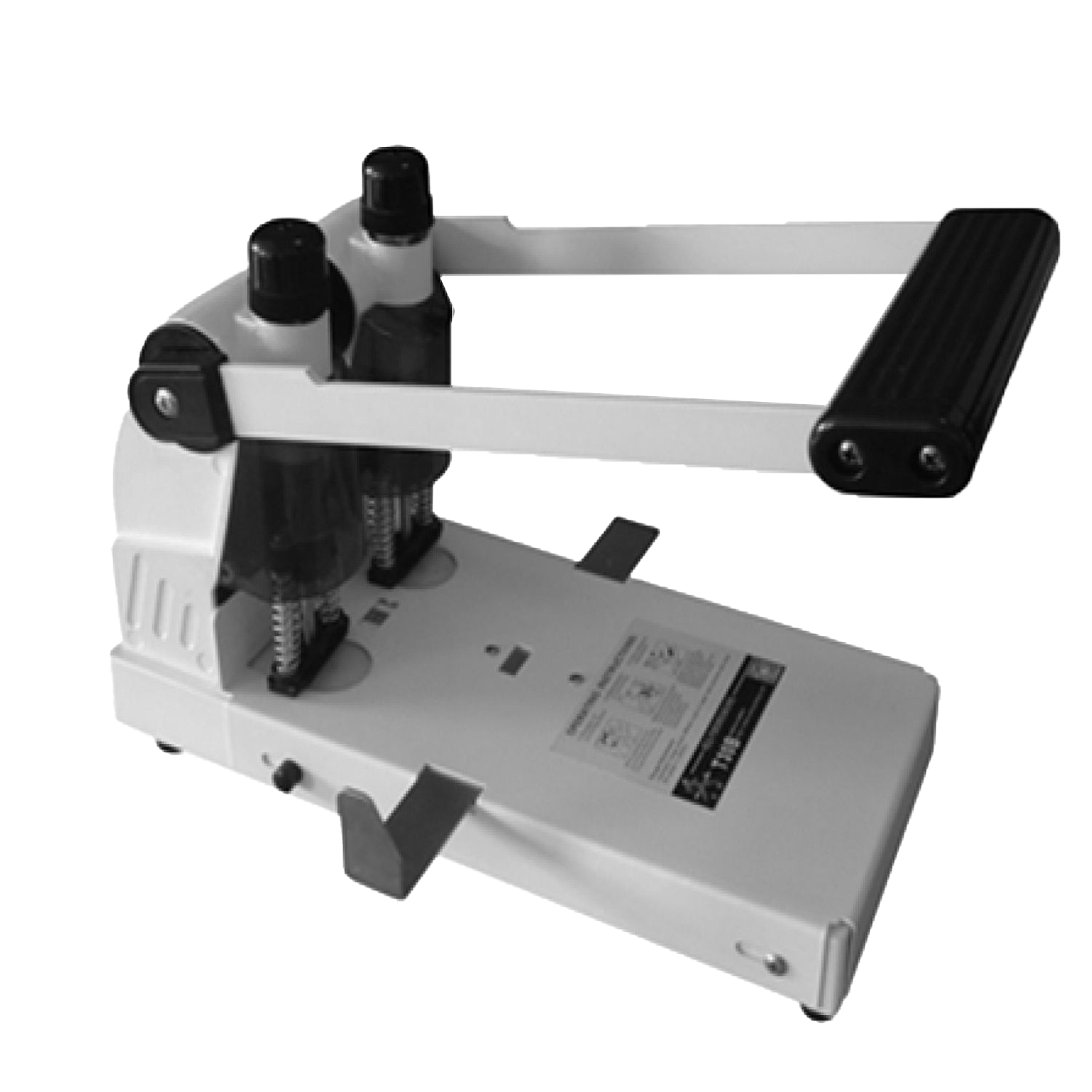

Okoboji Hole Punch Manual 2 Head WYT30B

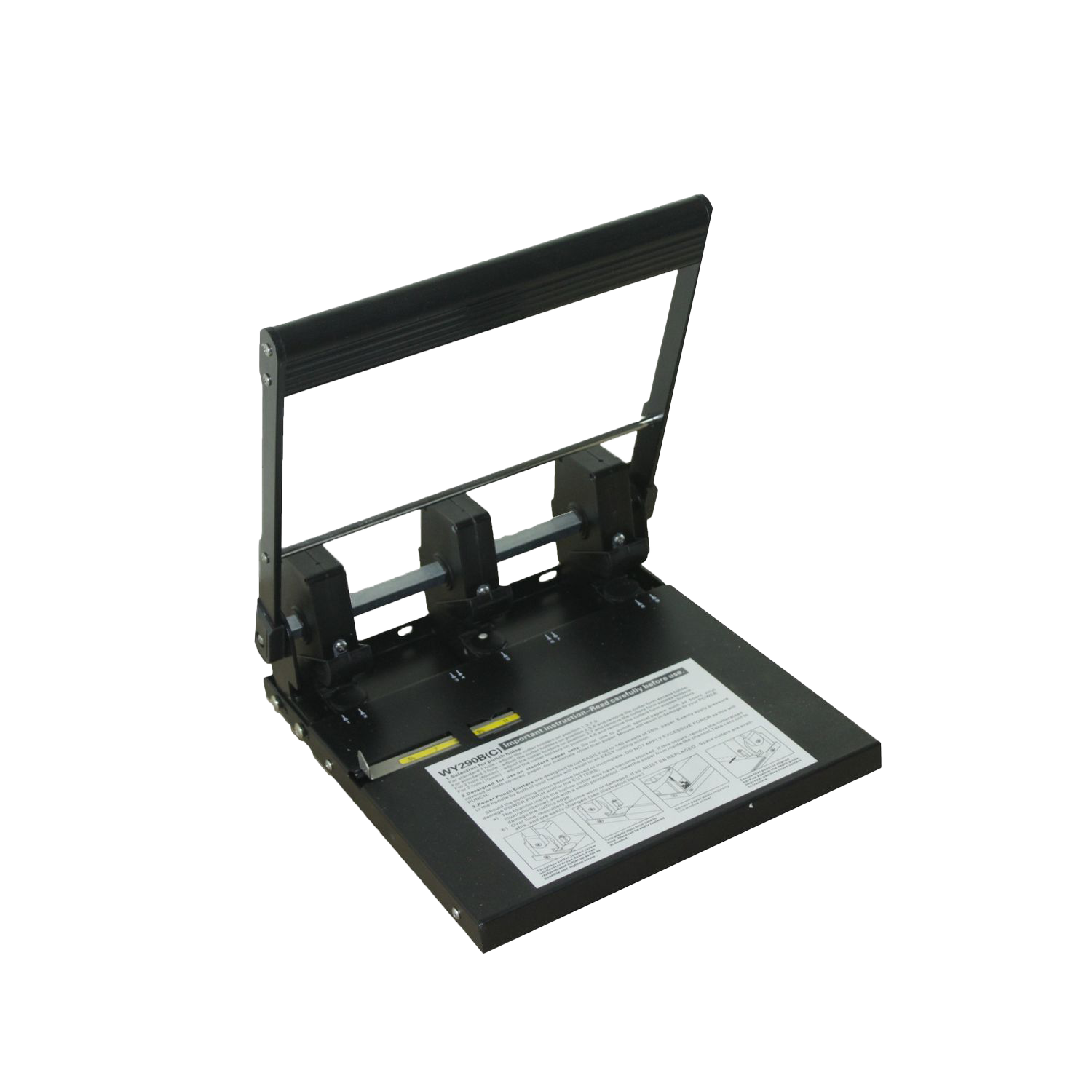

Okoboji Hole Punch Manual 3 Head WY290B

KEY FEATURES

- High-capacity dual-head design processes up to 500 pages simultaneously, dramatically increasing productivity for commercial binding and educational material preparation

- Precision hole spacing configuration of 80mm and 70mm ensures consistent, professional results compatible with standard binding systems used across Indian institutions

- Adjustable diameter range (3-6mm) accommodates spiral binding, ring binders, and various binding methods commonly required in educational and commercial applications

- Generous 400x210mm work plate handles multiple document sizes including A4, legal, and custom formats while ensuring stable, accurate positioning during operation

- Professional electric operation eliminates manual strain and fatigue while delivering consistent, high-speed punching performance for demanding commercial environments

- Flexible margin adjustment (8-35mm) ensures precise hole placement for different document formats and binding requirements, reducing waste and improving efficiency

- Robust 25.5kg construction provides stability and vibration control during high-volume operation while maintaining portability for workspace flexibility

- Okoboji commercial-grade reliability delivers consistent performance backed by comprehensive service support and proven durability for intensive daily use

FREQUENTLY ASKED QUESTIONS

Can the Okoboji WYT50 handle the volume requirements of a commercial printing operation?

Yes, with 500-page capacity and electric operation, this machine is specifically designed for commercial printing houses, educational institutions, and high-volume binding operations requiring consistent daily productivity.

How do the dual holes spacing options (80mm and 70mm) benefit different binding applications?

The dual spacing options accommodate various binding standards, ring binder sizes, and custom applications, ensuring compatibility with different document formats and binding system requirements.

What maintenance schedule is recommended for continuous commercial operation?

Regular cleaning of punch mechanisms, lubrication of moving parts, and electrical connection inspection ensure optimal performance. Okoboji provides detailed maintenance schedules for commercial applications.

Is this electric punch suitable for different paper weights and binding cover materials?

The 50mm capacity handles various paper weights, light cardstock, and thin binding covers. For heavy covers, consult Okoboji technical support for specific material recommendations.

How does the electric operation improve efficiency compared to manual alternatives?

Electric operation eliminates operator fatigue, provides consistent punching force, reduces processing time significantly, and enables continuous operation for high-volume production requirements.

What power consumption and electrical requirements should be considered for installation?

This electric punch operates on standard Indian electrical supply. Consider dedicated circuits for continuous operation and consult with qualified electricians for proper installation.

Can the work plate accommodate oversized documents or non-standard paper formats?

The 400x210mm work plate handles most standard documents. For oversized materials, proper positioning and multiple punching operations can accommodate larger format requirements.

Are safety features included to protect operators during high-volume operation?

Yes, the design includes safety features for operator protection. Proper training on safety procedures and adherence to operational guidelines ensure safe, efficient use.

How does Okoboji support service and technical assistance for commercial customers?

Okoboji provides comprehensive commercial support including installation assistance, operator training, maintenance schedules, and rapid parts availability for minimal downtime.

What is the expected return on investment for commercial binding operations?

The increased productivity, reduced labour costs, and consistent quality typically provide rapid return on investment for commercial operations, especially with high-volume daily requirements.

Customers also bought

Okoboji Eyelet Manual Dual Head 5.5mm DJS4

Okoboji Eyelet Manual Single Head Foot Pedal 5.5mm DJJ4

Okoboji Paper Cutter Digital Electric 490mm LCD