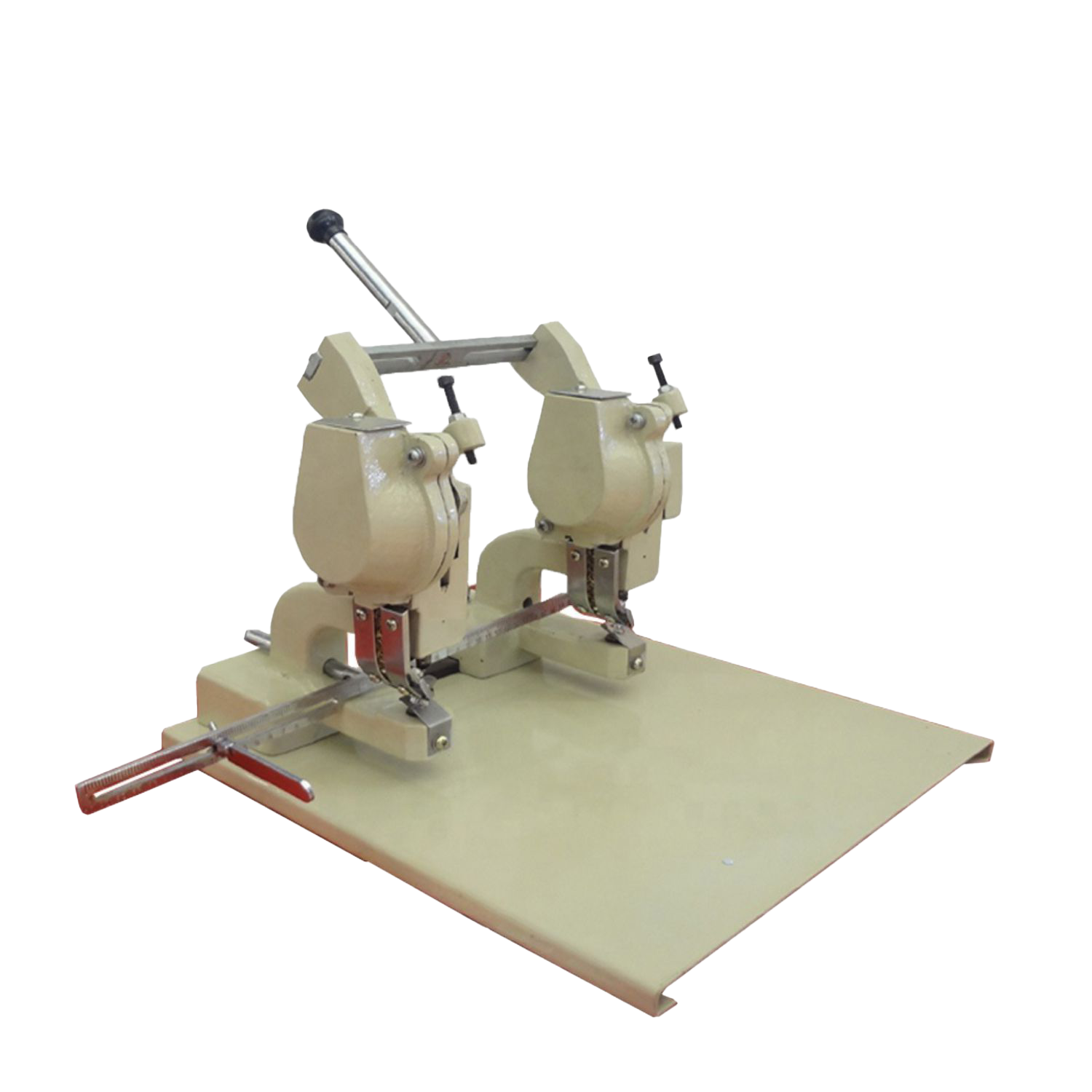

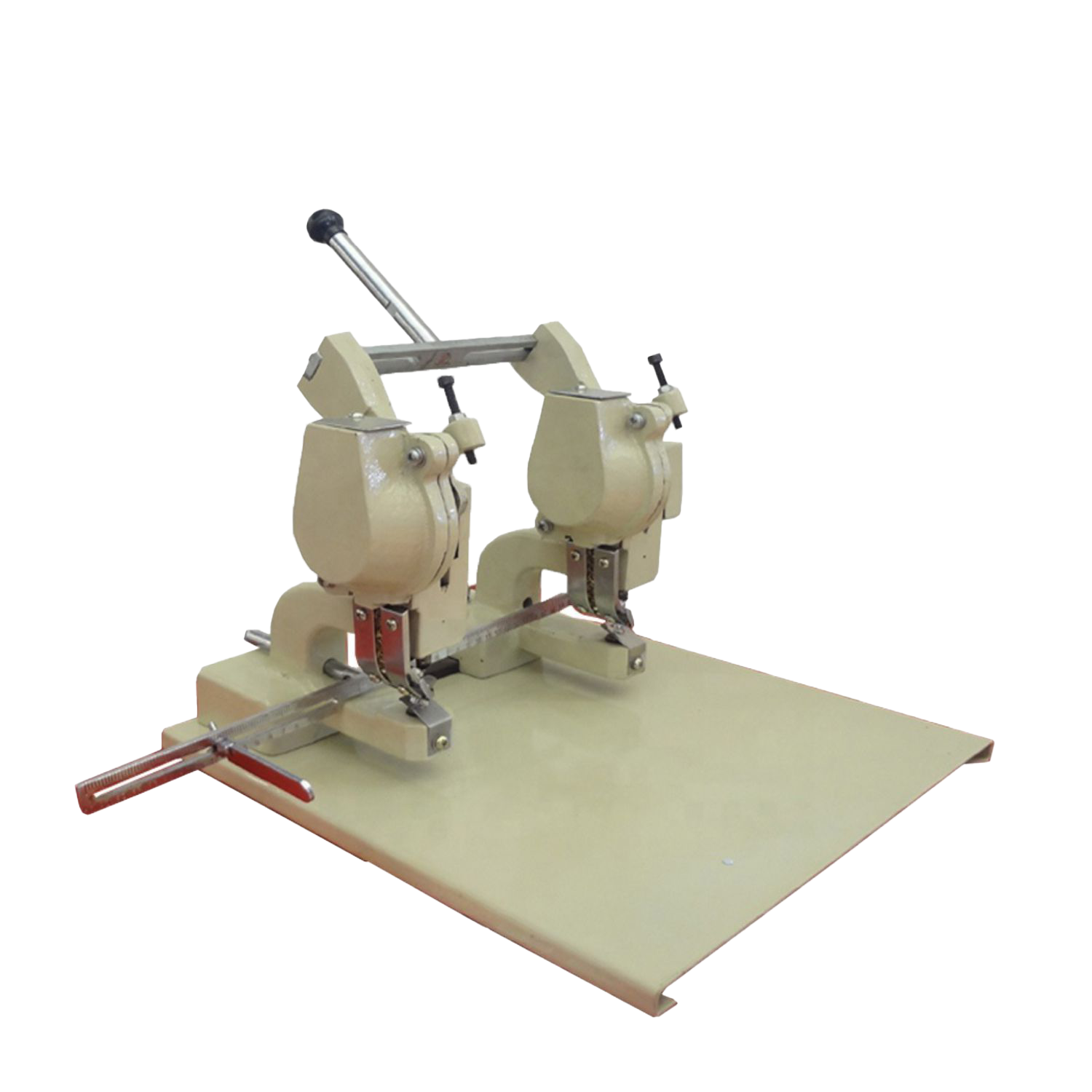

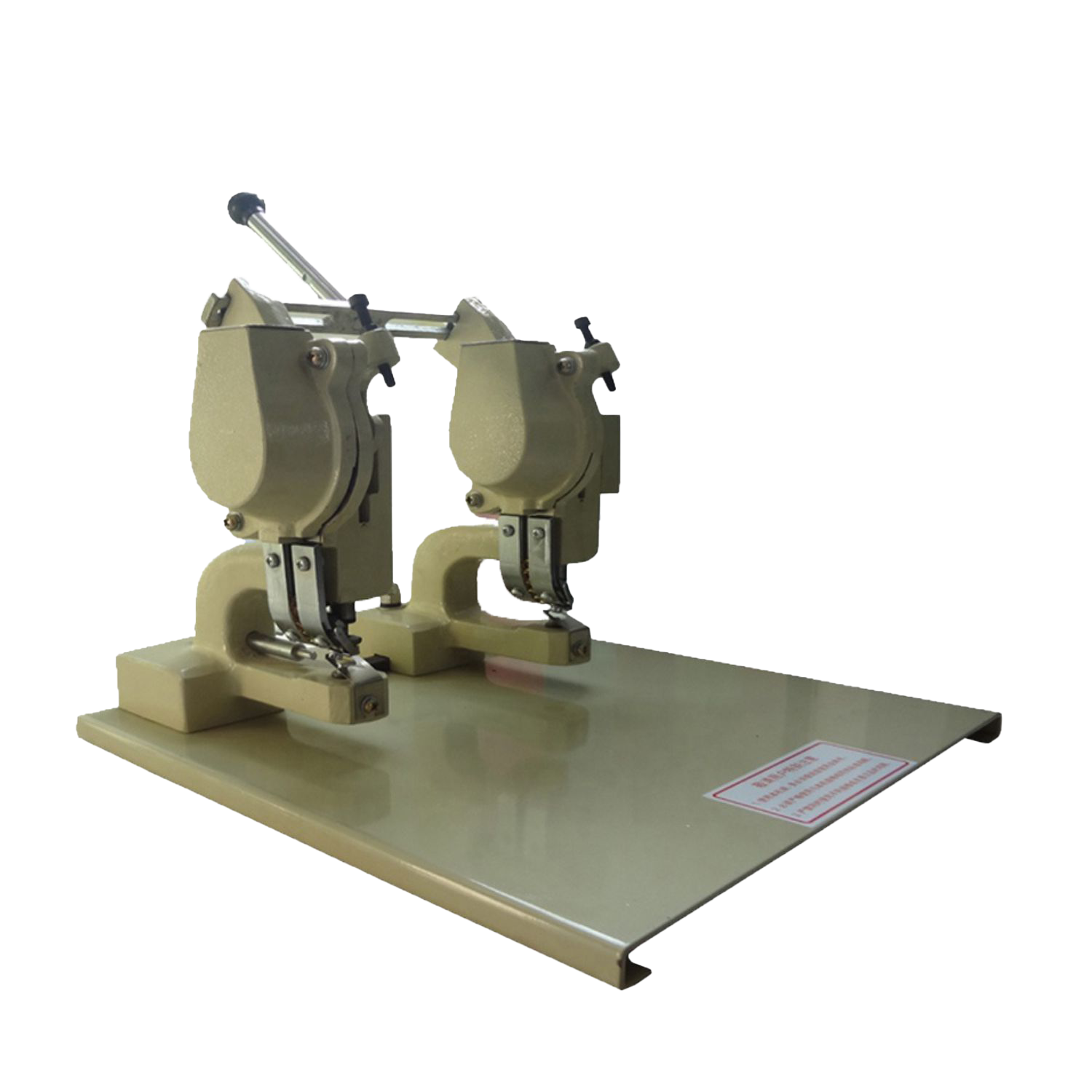

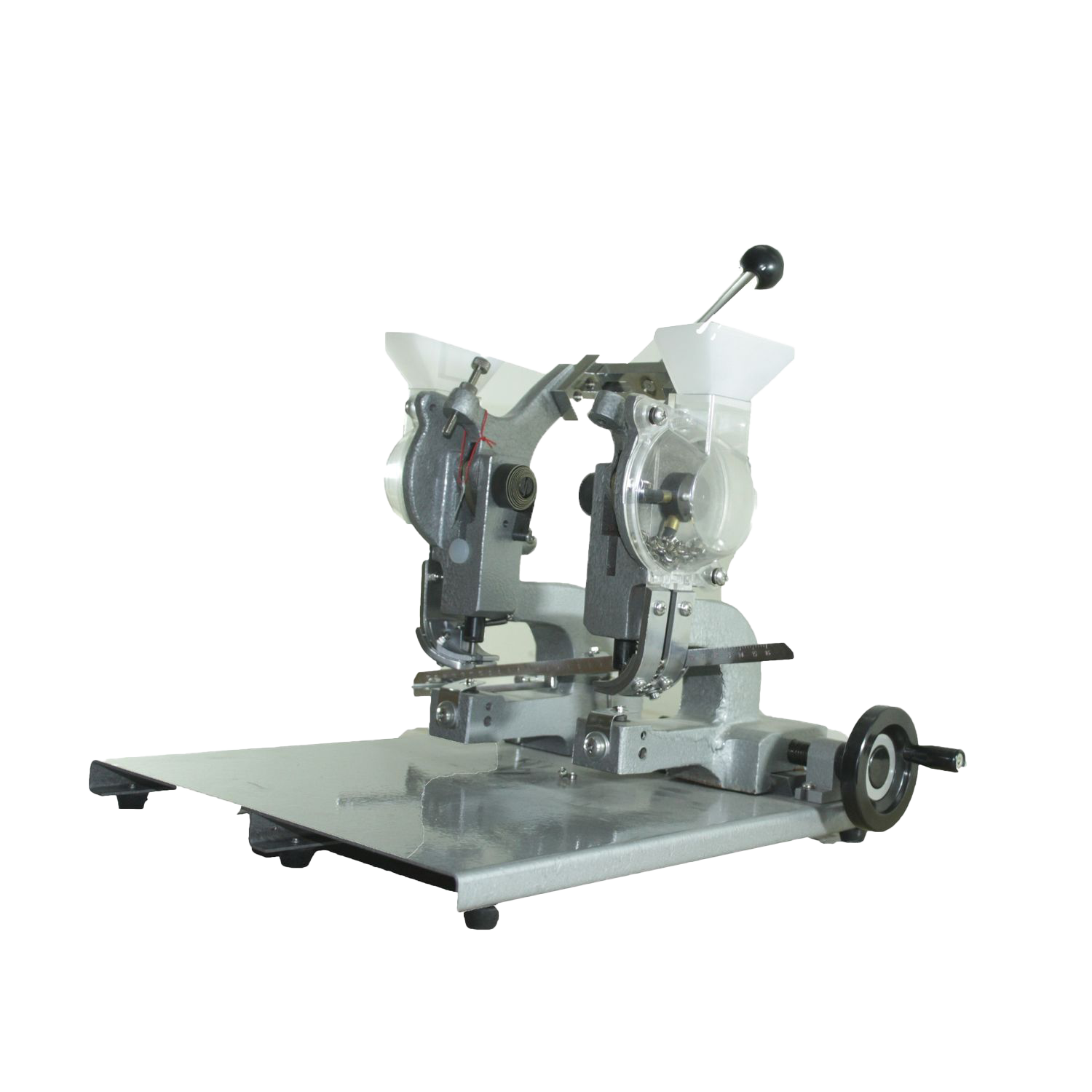

Okoboji Eyelet Manual Dual Head 5.5mm DJS4

SPECIFICATIONS

PRODUCT VIDEO

PRODUCT DESCRIPTION

The Okoboji Manual Dual Head 5.5mm DJS4 Eyelet Machine delivers superior manual eyeleting performance for applications requiring larger eyelet sizes combined with the efficiency benefits of dual-head operation. This machine represents the pinnacle of manual eyelet technology, specifically engineered for businesses that need robust, reliable eyeleting capabilities for heavy-duty materials and applications where 5.5mm eyelets provide optimal strength and durability.

Designed with the demands of industrial manufacturing in mind, this Okoboji machine excels in applications involving thicker materials, heavy-duty textiles, tarpaulins, and leather goods where larger eyelets are essential for structural integrity and longevity. The dual-head configuration ensures maximum productivity whilst the manual operation provides the precise control necessary for consistent, high-quality results across demanding applications.

The robust construction and thoughtful engineering make this Okoboji system particularly valuable for Indian manufacturers working with diverse materials and requiring the flexibility to operate independently of electrical infrastructure. The substantial build quality and precision engineering ensure reliable performance throughout extended production runs whilst maintaining the operational cost advantages that manual systems provide.

Upgrade Your Experience

Okoboji Eyelet Electric 5.5mm Dual Head

Okoboji Eyelet Manual Dual Head 4mm DJS4 4mm

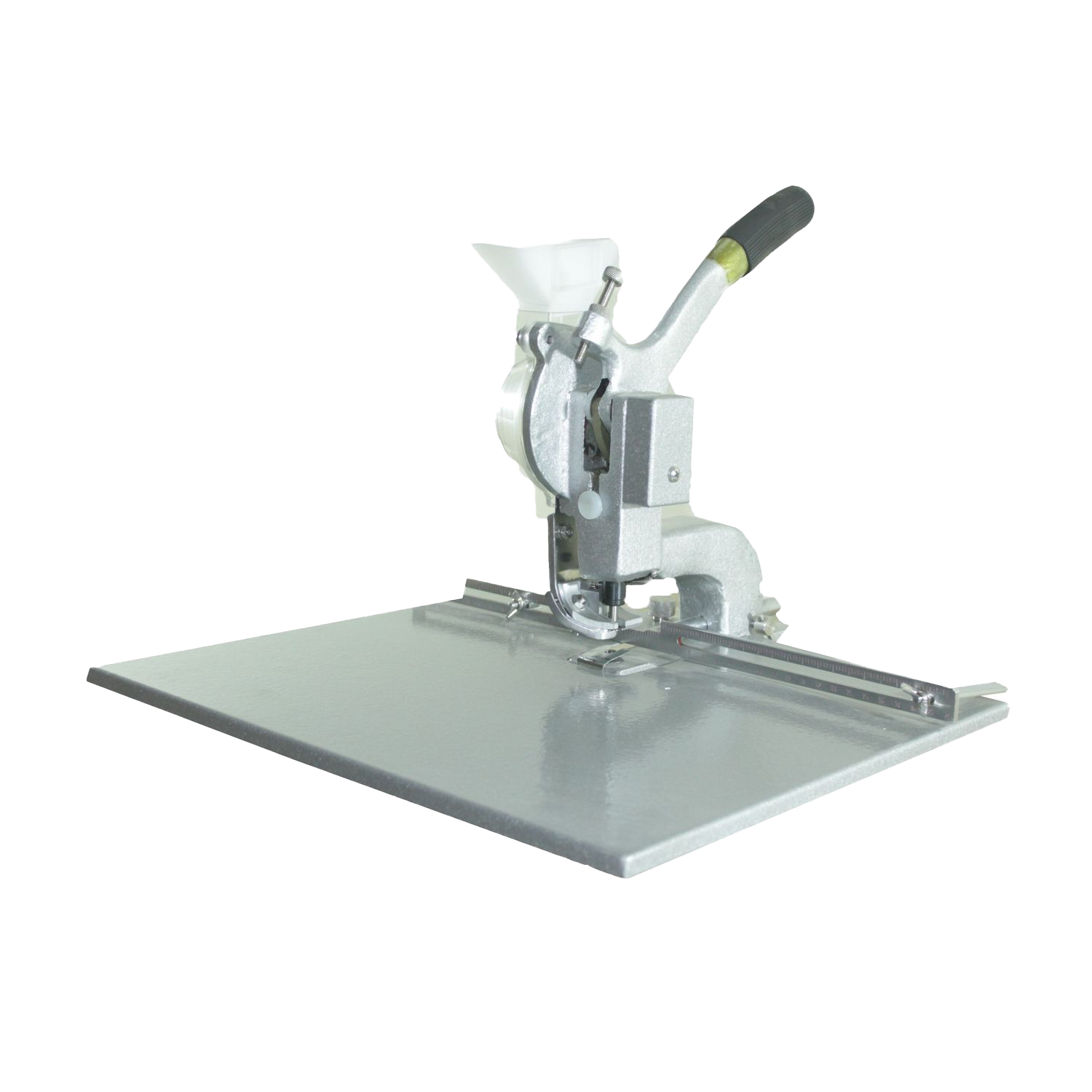

Okoboji Eyelet Manual Single Head 4mm DJC4 4mm

Okoboji Eyelet Manual Single Head Foot Pedal 5.5mm DJJ4

KEY FEATURES

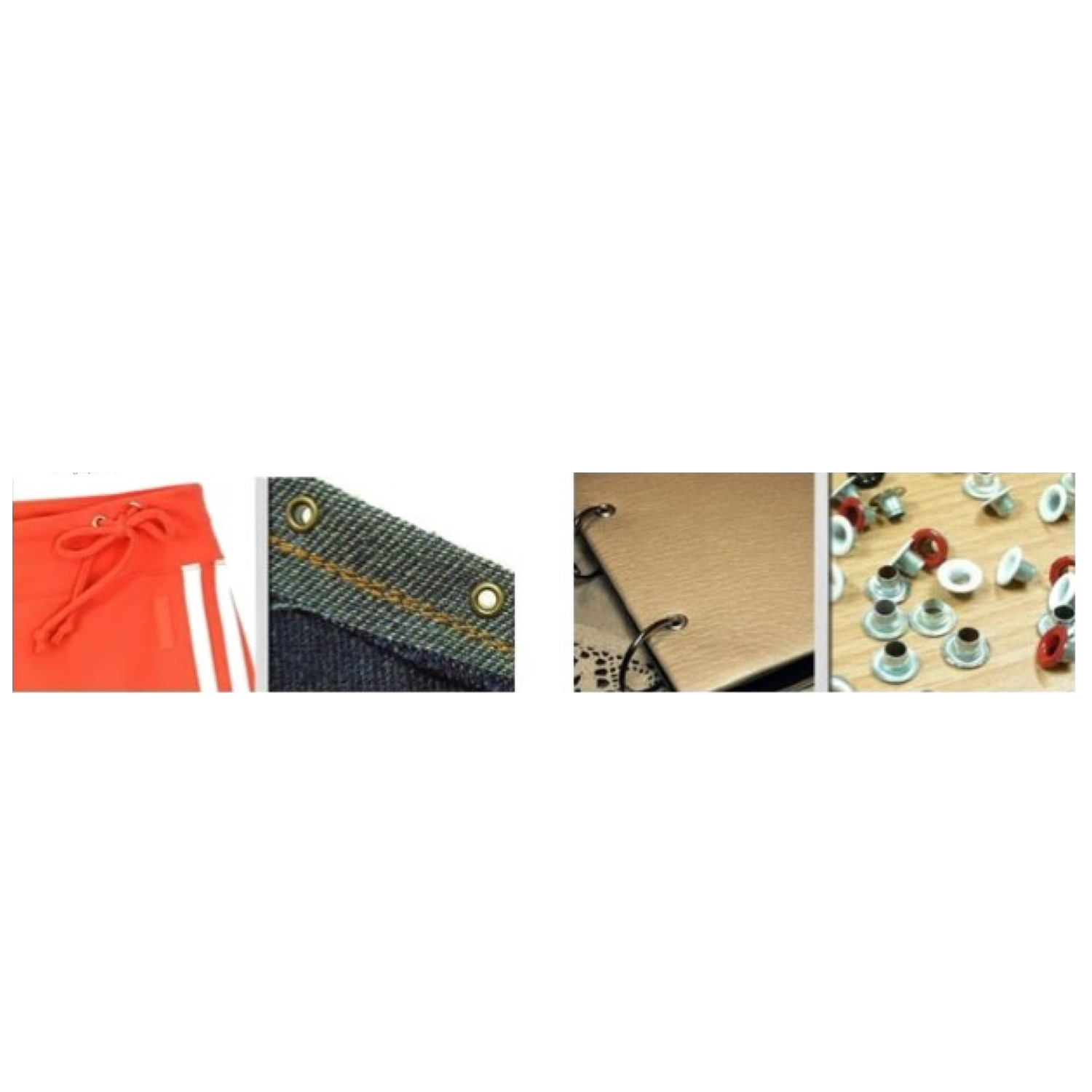

- 5.5mm Large Eyelet Capacity : Okoboji's 5.5mm eyeleting capability provides superior holding strength for heavy-duty applications, making this machine ideal for tarpaulins, heavy textiles, industrial materials, and applications requiring robust eyelet connections.

- Enhanced Dual Head Productivity : Advanced dual-head design doubles production output compared to single-head alternatives, enabling simultaneous installation of two large eyelets that significantly improves manufacturing efficiency for demanding applications.

- Industrial Manual Construction : Heavy-duty 28kg construction with precision engineering ensures reliable operation throughout demanding production environments, whilst manual operation provides superior control over eyeleting pressure and positioning.

- Extended Operation Capacity : Substantial 1200-grain eyelet container capacity minimises production interruptions during large-scale manufacturing runs, maintaining consistent workflow throughout extended production schedules with this Okoboji system.

- Versatile Working Range : Adjustable vertical travel (60-165mm) and hold setting range (80-130mm) accommodate diverse material thicknesses and applications, providing flexibility for varied manufacturing requirements across multiple industries.

- Foot-Operated Efficiency : Manual foot operation keeps operators' hands free for precise material handling whilst providing excellent control over eyeleting force, ensuring consistent quality results throughout extended production periods.

- Power-Independent Operation : Manual operation eliminates electrical dependency, making this Okoboji machine perfect for locations with unreliable power, remote facilities, or businesses seeking to minimise operational power costs.

- Professional Grade Results : Delivers consistently precise 5.5mm eyelet installation that meets industrial quality standards, ensuring product durability and professional appearance across demanding applications requiring larger eyelet sizes.

FREQUENTLY ASKED QUESTIONS

What applications benefit most from the 5.5mm eyelet size compared to smaller alternatives?

The 5.5mm size is ideal for tarpaulins, heavy canvas, industrial textiles, leather goods, and applications requiring superior holding strength. This Okoboji machine excels where larger eyelets provide better durability and load distribution.

How does the dual head configuration improve efficiency for large eyelet applications?

Dual head operation doubles productivity by installing two 5.5mm eyelets simultaneously, significantly reducing production time for large-scale applications. This Okoboji design is particularly valuable for heavy-duty manufacturing requiring numerous large eyelets.

What material thickness range can this Okoboji machine handle effectively?

The machine accommodates materials up to 3mm thickness with adjustable working travel from 60-165mm. This range covers most industrial applications including heavy leather, multiple fabric layers, and thick canvas materials commonly used in demanding applications.

How does manual operation benefit precision work with larger eyelets?

Manual control allows operators to adjust pressure and positioning precisely for each eyelet, ensuring optimal installation in varying materials. This Okoboji manual system provides superior control compared to automated alternatives for specialised applications.

What are the operational cost advantages of this manual Okoboji system?

Manual operation eliminates electricity costs, reduces maintenance complexity, and provides independence from power infrastructure. This makes the Okoboji machine extremely cost-effective for businesses prioritising low operational expenses with reliable performance.

How long does operator training typically take for this dual head machine?

Training usually requires 3-4 days covering dual head coordination, material handling techniques, machine adjustments, and safety procedures. The manual nature makes this Okoboji machine intuitive for operators experienced with manual machinery.

Can this machine handle continuous heavy-duty production schedules?

Yes, the robust 28kg construction and heavy-duty components enable sustained operation throughout standard industrial shifts. The manual operation eliminates motor fatigue issues, making this Okoboji machine ideal for continuous production requirements.

What maintenance schedule ensures optimal performance for this manual machine?

Weekly lubrication of moving parts, daily cleaning, and monthly mechanical inspections maintain optimal performance. The manual operation significantly reduces maintenance complexity compared to electric alternatives, making this Okoboji system very reliable.

How does the 1200-grain capacity affect production workflow?

The large capacity provides approximately 2-4 hours of continuous operation depending on production speed, minimising interruptions and maintaining smooth workflow. This capacity is particularly valuable for large-scale production runs with this Okoboji machine.

What technical support does Okoboji provide for manual dual head machines?

Okoboji offers comprehensive support including installation assistance, operator training, maintenance guidance, spare parts availability, and technical troubleshooting. Our service team understands the specific requirements of manual dual head operations.

Customers also bought

Okoboji Hole Punch Electric Drill 2 Head HD WYT50

Okoboji Hole Punch Manual 4 Head WY290C

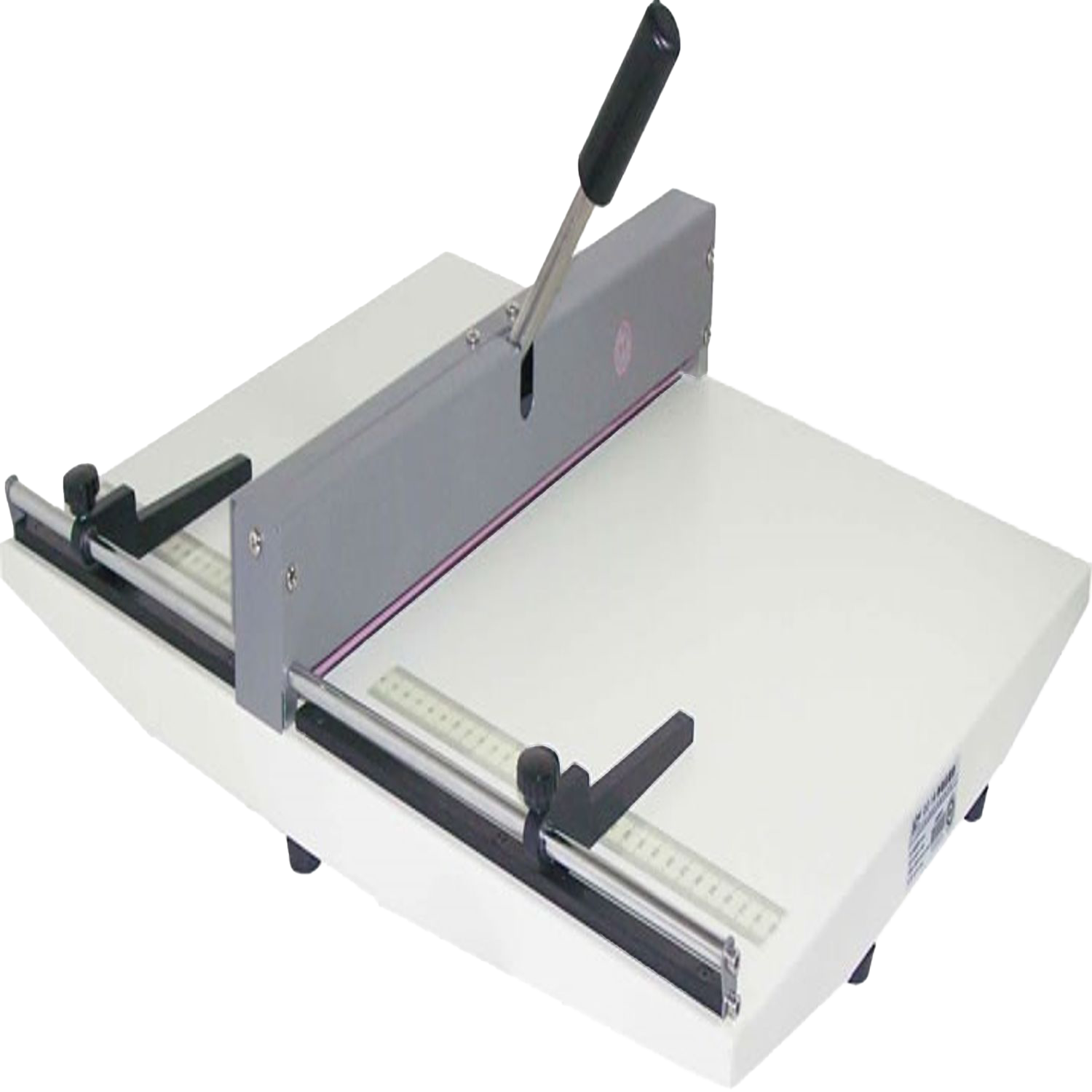

Okoboji Paper Creaser Manual A3 Size H460