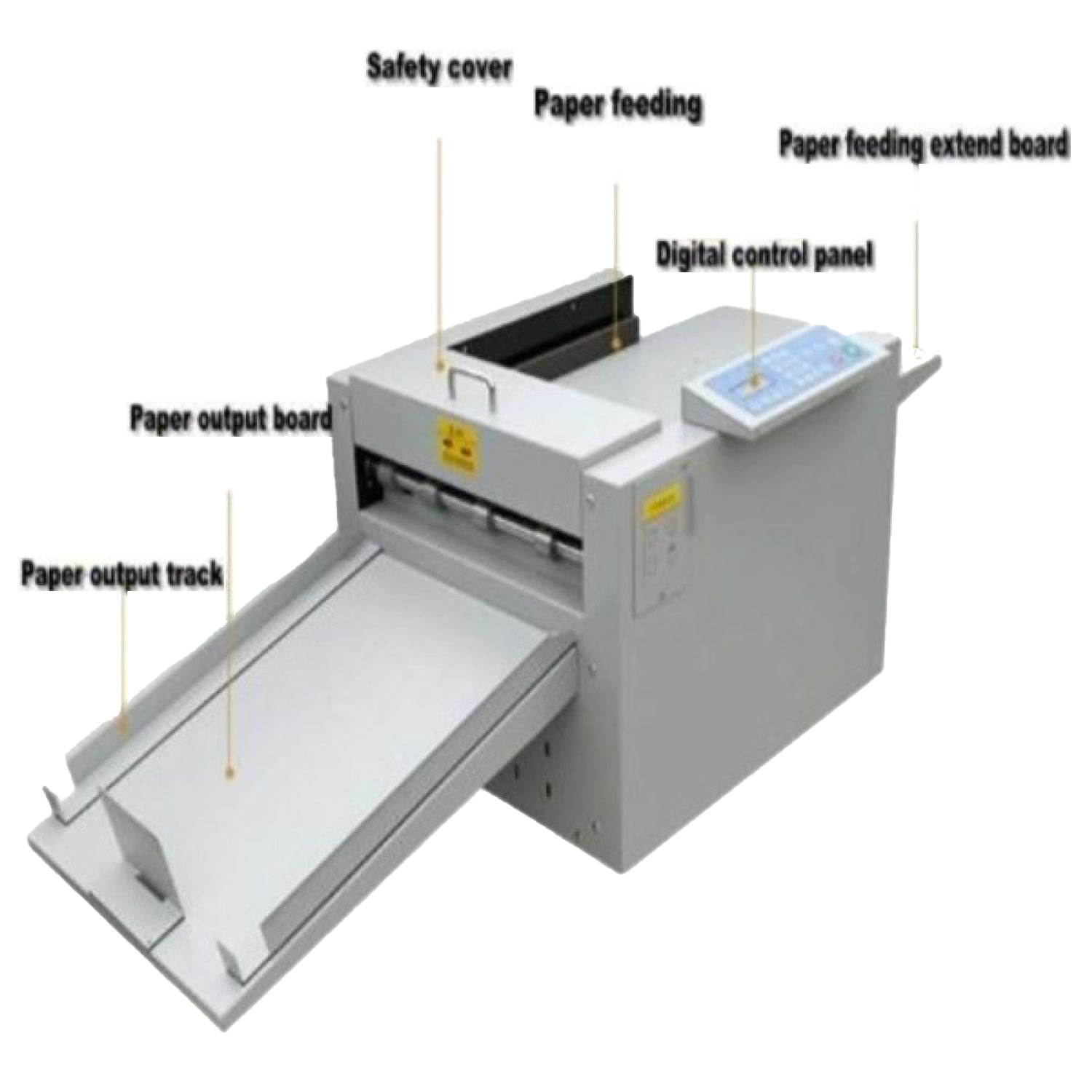

Okoboji Paper Creaser Automatic 13″ 330mm ACM13

SPECIFICATIONS

PRODUCT VIDEO

PRODUCT DESCRIPTION

The Okoboji ACM13 Automatic Paper Creaser represents cutting-edge technology in professional paper finishing equipment, specifically engineered for high-volume commercial printing and packaging operations. This robust 13-inch electric creasing machine delivers exceptional precision in creating clean, professional fold lines on various paper weights without compromising print quality or causing unsightly cracks in digitally printed materials. The 330mm maximum width capacity makes it ideal for processing A3-sized documents, brochures, catalogues, and packaging materials commonly used in Indian businesses.

This versatile machine excels in commercial printing environments, binderies, and packaging facilities where consistent, high-quality creasing is essential for professional presentation. The interchangeable die system allows operators to switch seamlessly between creasing and perforation functions, making it perfect for creating tear-off coupons, tickets, invoices, and professional marketing materials. With its manual feeding system, operators maintain complete control over paper positioning whilst benefiting from automated creasing precision, ensuring every fold meets professional standards demanded by modern businesses.

Upgrade Your Experience

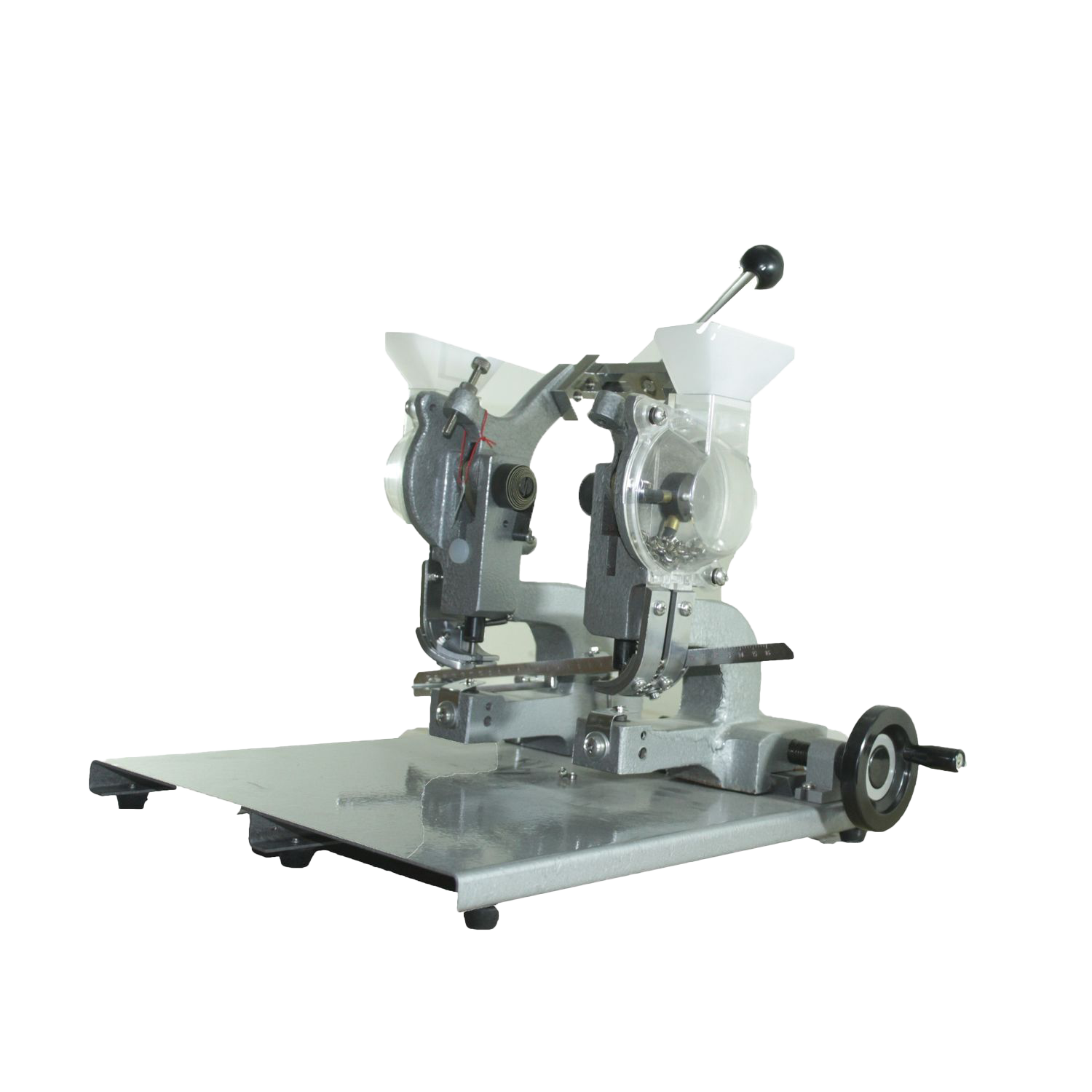

Okoboji Creasing and Perforation Rotary Electric A3

Okoboji Paper Creaser Automatic W auto pickup K330C

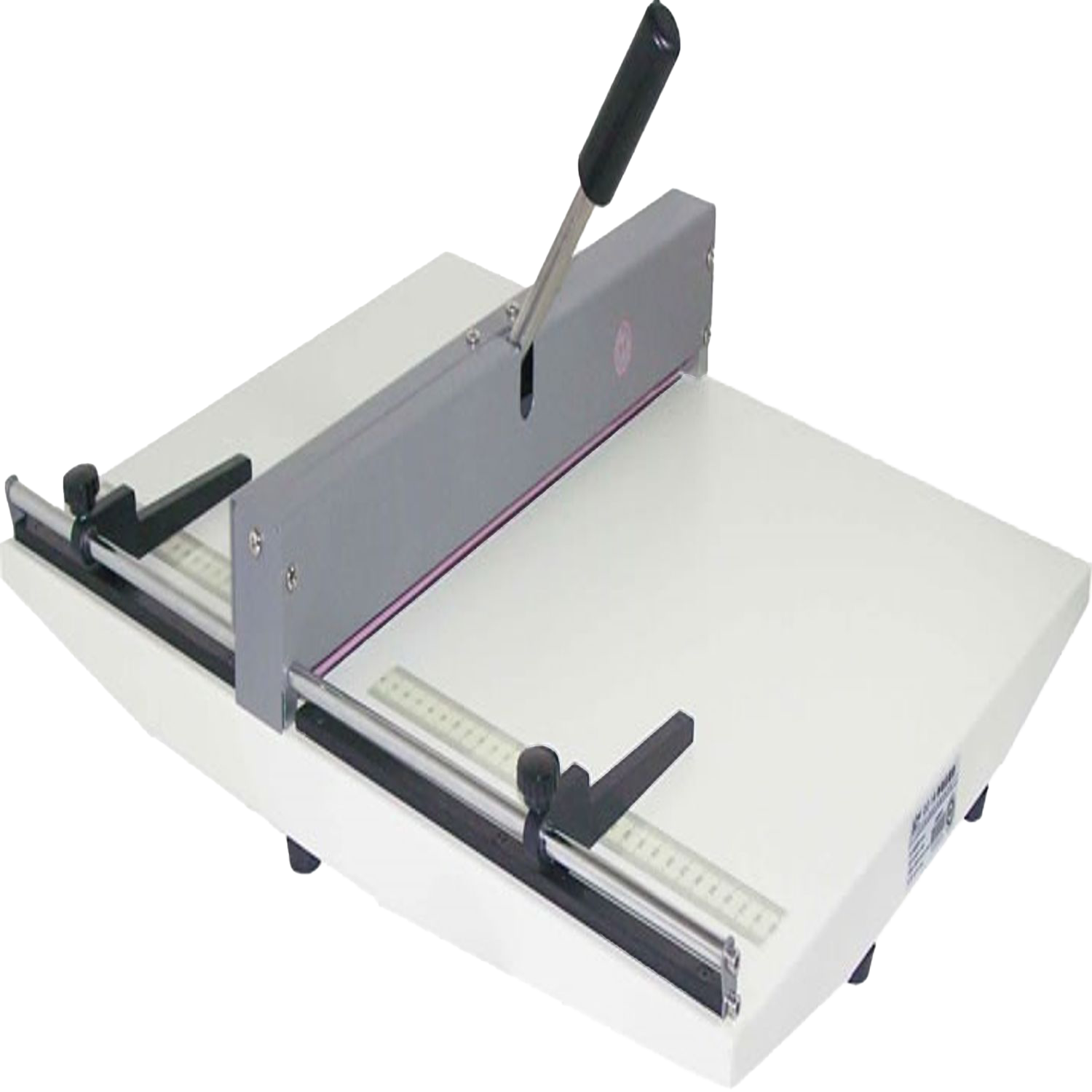

Okoboji Paper Creaser Manual A3 Size H460

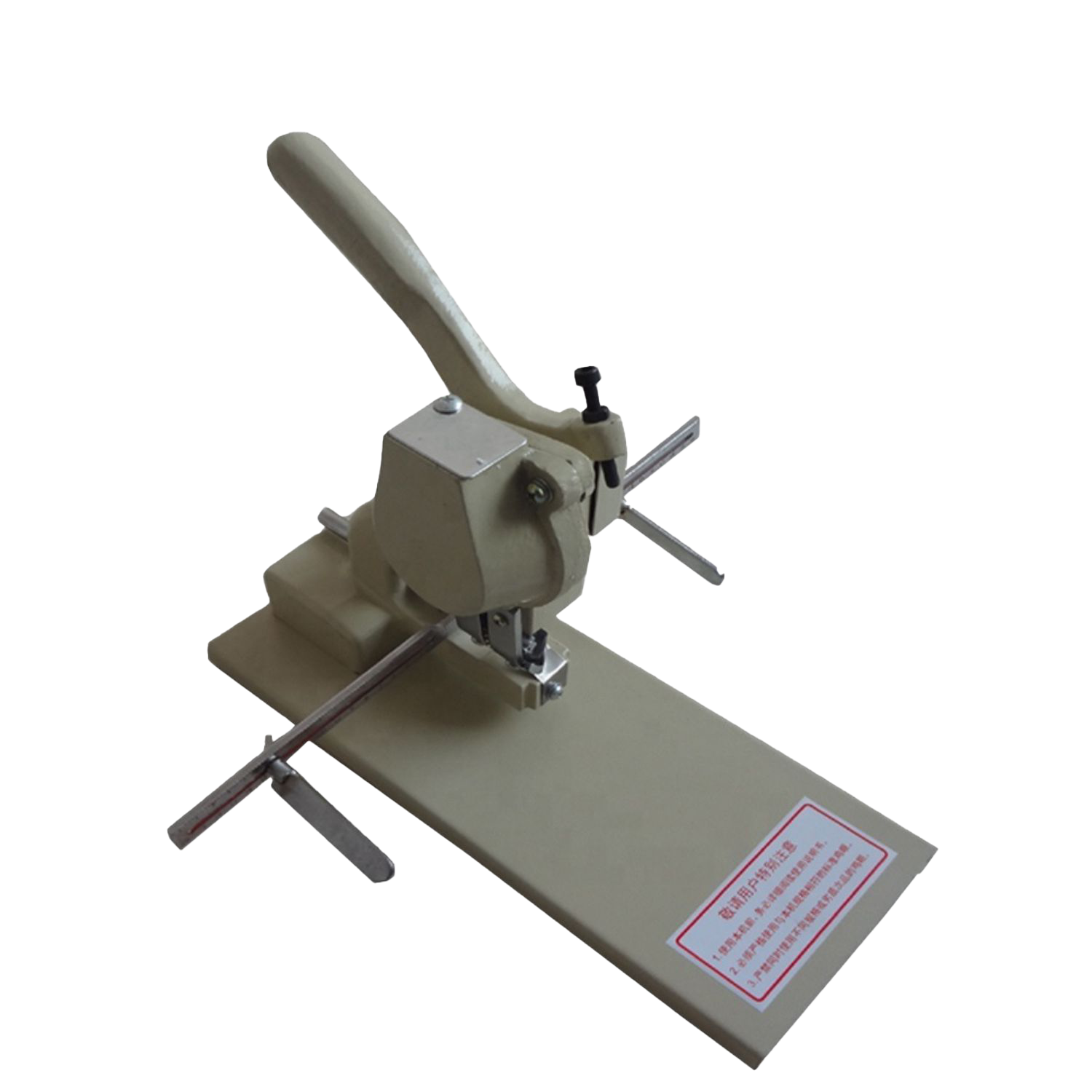

Okoboji Paper Creasing, Perforation Manual 460 2in1

KEY FEATURES

- Advanced Electric Motor System : Powered by precision-engineered motor delivering consistent creasing force across the entire 330mm width for uniform, professional results every time

- Interchangeable Die Technology : Quick-change creasing and perforation dies allow seamless switching between functions, maximising productivity and versatility for diverse applications

- Manual Feed Control : Operator-controlled feeding system ensures precise paper positioning whilst maintaining high throughput rates ideal for commercial printing operations

- Professional-Grade Construction : Heavy-duty steel frame and precision-machined components ensure years of reliable operation in demanding commercial environments

- Wide Format Capability : 330mm maximum width accommodates A3 documents, large brochures, and packaging materials commonly used in Indian business applications

- Okoboji Quality Assurance : Backed by comprehensive warranty and nationwide service support, ensuring minimal downtime and maximum productivity for your operations

- Crack-Free Creasing : Advanced creasing mechanism prevents toner cracking and paper fibre damage, maintaining print quality on digitally printed materials

- High-Volume Performance : Designed for continuous operation in busy commercial environments with consistent results throughout extended production runs

FREQUENTLY ASKED QUESTIONS

What paper weights can the Okoboji ACM13 handle effectively?

The ACM13 processes paper weights from 80gsm to 400gsm, including lightweight office paper, cardstock, cover stock, and packaging materials commonly used in Indian printing applications.

How quickly can I switch between creasing and perforation functions?

The interchangeable die system allows tool changes within 2-3 minutes, minimising downtime and maximising productivity during multi-function jobs.

Does this machine work with digitally printed materials without damaging toner?

Yes, the precision creasing mechanism is specifically designed to create clean folds without cracking toner or damaging digital prints, making it perfect for modern printing operations.

What maintenance is required for the Okoboji ACM13?

Regular cleaning, monthly lubrication of moving parts, and periodic die inspection ensure optimal performance. Okoboji provides comprehensive maintenance guidelines and local service support.

Can this machine handle coated and glossy papers?

Absolutely, the controlled pressure system works excellently with coated stocks, glossy papers, and laminated materials without causing surface damage or delamination.

What safety features are included in this machine?

The ACM13 includes emergency stop controls, safety guards, and operator protection features meeting international safety standards for commercial equipment.

How does this compare to manual creasing methods?

The electric system delivers 10-15 times faster processing speeds with superior consistency and reduced operator fatigue compared to manual scoring tools.

What warranty and service support does Okoboji provide?

nationwide service network with technical support and genuine spare parts availability across major Indian cities.

Is training required to operate this machine safely?

Basic operator training is recommended; the intuitive design allows skilled operators to achieve proficiency within hours of initial instruction.

What industries benefit most from the ACM13 model?

Commercial printing, packaging, binderies, corporate print centres, educational institutions, and government printing facilities requiring high-quality finishing operations.

Customers also bought

Okoboji Eyelet Manual Dual Head 4mm DJS4 4mm

Okoboji Eyelet Manual Single Head 5.5mm DJC4

Okoboji Hole Punch Electric Drill 2 Head HD WYT50