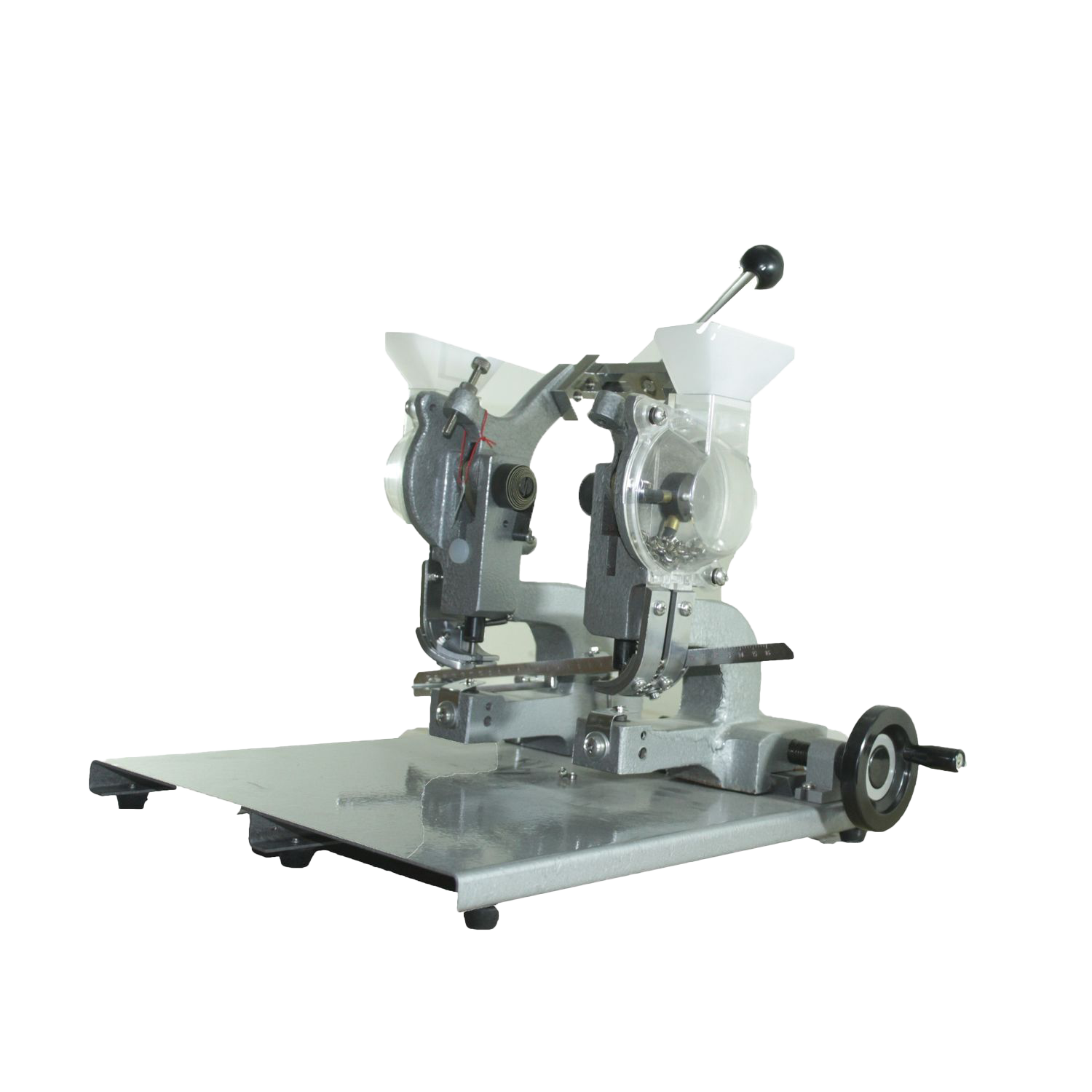

Okoboji Paper Creaser Automatic W auto pickup K330C

SPECIFICATIONS

PRODUCT VIDEO

PRODUCT DESCRIPTION

The Okoboji K330C represents the pinnacle of automated paper finishing technology, featuring advanced computerised controls and automatic pickup feeding system designed for high-volume commercial and industrial applications. This sophisticated creasing and perforating machine transforms workflow efficiency by eliminating manual feeding requirements, allowing operators to focus on quality control whilst the machine automatically processes large quantities of documents with exceptional precision. The 230W power system delivers consistent performance across extended production runs, making it indispensable for commercial printing facilities, large binderies, and packaging operations requiring superior throughput capabilities.

This premium automatic machine excels in demanding environments where productivity and consistency are paramount. The computerised control system ensures repeatable results across thousands of sheets, whilst the auto-pickup mechanism handles various paper weights and sizes with remarkable reliability. Perfect for processing invoices, brochures, packaging materials, and commercial documents, the K330C significantly reduces labour costs whilst improving output quality. The robust 140kg construction guarantees stability during high-speed operations, whilst the comprehensive safety systems protect operators and maintain consistent production standards throughout demanding commercial applications.

Upgrade Your Experience

Okoboji Creasing Machine Automatic 12.5" ACM12

Okoboji Paper Creaser Automatic 13" 330mm ACM13

Okoboji Paper Creasing, Perforation Manual 460 2in1

Okoboji Paper Half Cutting 600mm HC600

KEY FEATURES

- Computerised Control System : Advanced digital controls with programmable settings ensure consistent, repeatable results across large production runs with minimal operator intervention

- Automatic Pickup Feeding : Revolutionary auto-feed mechanism eliminates manual sheet feeding, dramatically increasing productivity whilst reducing operator fatigue and labour costs

- High-Performance 230W Motor : Powerful electric drive system delivers consistent creasing force and reliable operation throughout extended commercial production schedules

- Industrial-Grade Construction : Massive 140kg steel frame ensures vibration-free operation and exceptional stability during high-speed processing in demanding environments

- Dual Function Capability : Seamlessly switches between precision creasing and micro-perforation functions, maximising versatility for diverse commercial applications

- Okoboji Commercial Support : Professional-grade warranty with dedicated technical support and nationwide service network ensuring minimal downtime for critical operations

- Large Format Processing : Accommodates wide range of paper sizes and weights, perfect for commercial printing, packaging, and large-format document finishing

- Safety-First Design : Comprehensive safety systems including emergency stops, protective guards, and operator safety features meeting international commercial equipment standards

FREQUENTLY ASKED QUESTIONS

How many sheets per hour can the Okoboji K330C process automatically?

The auto-pickup system processes 3000-5000 sheets per hour depending on paper weight and complexity, dramatically outperforming manual feeding systems.

What paper sizes and weights are compatible with the automatic feeding system?

The K330C handles paper weights from 80gsm to 350gsm in sizes from A5 to A3+, with automatic adjustment for different material thicknesses.

How reliable is the computerised control system for consistent results?

The digital control system maintains precision within 0.1mm across thousands of sheets, ensuring professional consistency throughout large production runs.

What happens if a paper jam occurs during automatic operation?

Intelligent sensors detect jams immediately, automatically stopping the machine and indicating the problem location, allowing quick resolution without damage.

Can the K330C handle different types of creasing and perforation in one job?

Yes, the computerised system allows programming multiple crease patterns and perforation styles within a single production run for complex applications.

What electrical requirements are needed for the K330C installation?

Standard AC220V power supply with stable voltage (±10% tolerance) and appropriate earthing for safe operation of the 230W motor system.

How does Okoboji ensure service support for this advanced machine?

Comprehensive warranty with certified technicians, remote diagnostic capabilities, and guaranteed spare parts availability across India's major commercial centres.

Is operator training required for the computerised controls?

Professional training is recommended for optimal performance; Okoboji provides comprehensive operator certification programmes for commercial users.

What safety certifications does this machine meet?

The K330C meets international safety standards including CE certification and local Indian electrical safety requirements for commercial equipment.

How does the automatic pickup system handle different paper finishes?

Advanced pickup technology works effectively with coated, uncoated, textured, and laminated papers without marking or damaging surface finishes.

Customers also bought

Okoboji Eyelet Manual 2 Head Foot Pedal EPDM2

Okoboji Eyelet Manual Dual Head 4mm DJS4 4mm

Okoboji Hole Punch Electric Drill 3 Head HD WYWB830