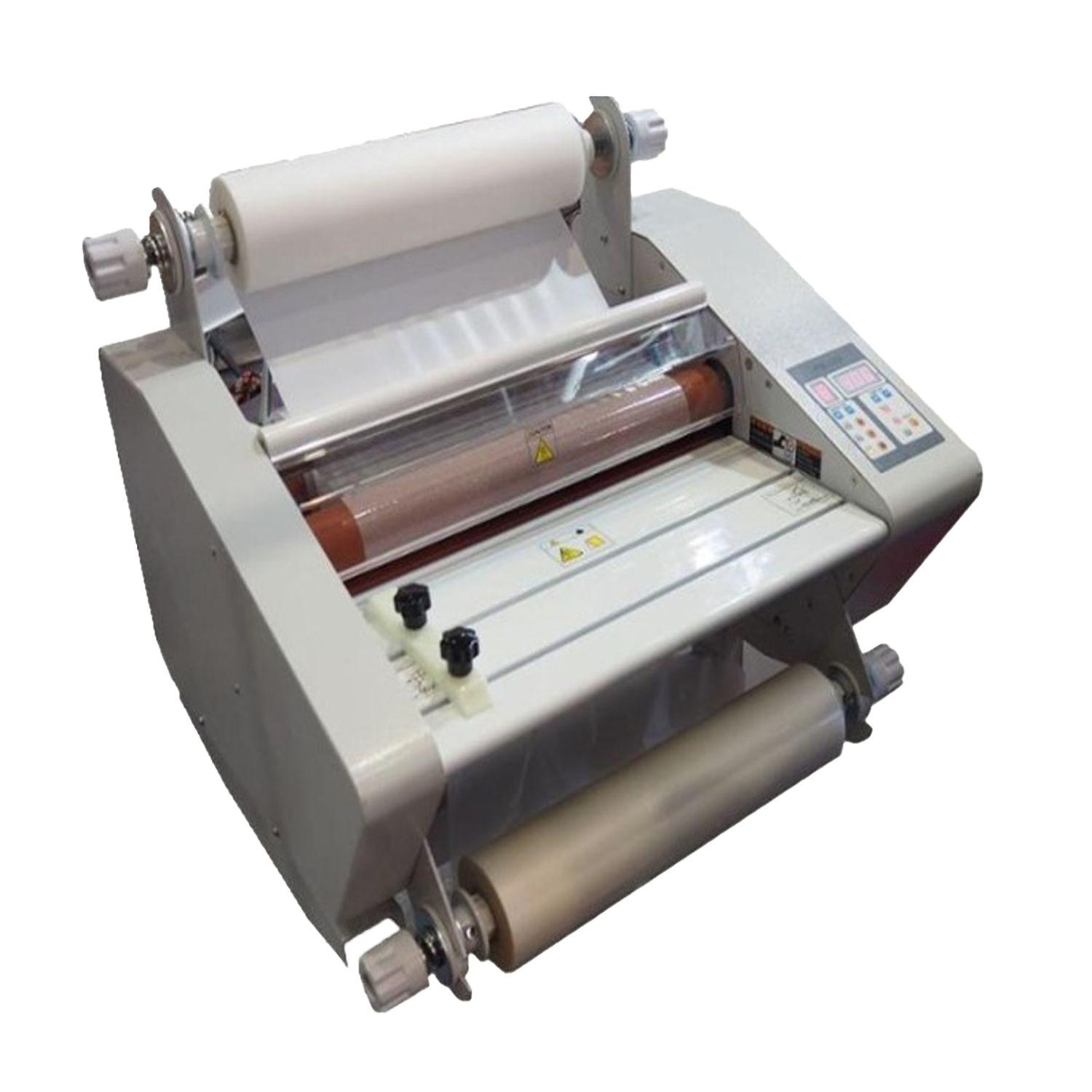

Okoboji Thermal Roll Laminator AutoSnap 520 mm

SPECIFICATIONS

PRODUCT VIDEO

PRODUCT DESCRIPTION

The Okoboji Thermal Roll Laminator AutoSnap 520mm represents the pinnacle of professional thermal lamination technology, incorporating advanced hydraulic pressure systems and precision engineering for the most demanding commercial and industrial applications. This sophisticated machine features an impressive 480mm maximum film width capacity, making it ideal for large-format graphics, architectural drawings, wide banners, and oversized promotional materials commonly required in India’s expanding advertising and construction industries. The AutoSnap designation reflects the machine’s intelligent automation features and precision control systems that ensure consistent professional results across diverse material types and thicknesses.

The revolutionary hydraulic pressure system delivers superior and uniform pressure distribution across the entire lamination width, while the massive 200mm diameter steel rollers provide exceptional heat retention and transfer characteristics. This combination enables processing speeds of up to 12,000mm per minute whilst maintaining optimal temperature control at 160°C maximum, making it suitable for high-volume production environments requiring both speed and quality. The substantial 240kg construction houses advanced components including AC motor drive systems, LED display controls, and sophisticated temperature management technology that ensures reliable operation during extended production runs.

With its generous 6mm maximum film thickness capacity and robust 4000W heating system, the AutoSnap 520 accommodates the most demanding lamination applications including heavy protective films, mounting materials, and specialised industrial substrates. This machine represents Okoboji’s commitment to providing Indian businesses with world-class lamination technology capable of meeting the most challenging requirements whilst delivering the precision, reliability, and performance essential for commercial success in competitive markets.

Upgrade Your Experience

Okoboji Okoboji Thermal Roll Laminator FM360 360mm

Okoboji Thermal Roll Laminator 1100mm FM1100

Okoboji Thermal Roll Laminator 358

Okoboji Thermal Roll Laminator Steel roller 360mm

KEY FEATURES

- Advanced hydraulic pressure system delivering superior uniform pressure distribution and consistent lamination quality across the full 480mm working width

- Impressive processing speeds up to 12,000mm/min with precise speed control enabling high-volume production whilst maintaining professional quality standards

- Massive 200mm diameter steel rollers providing exceptional heat retention, superior thermal transfer, and consistent temperature distribution for optimal results

- Professional 6mm maximum film thickness capacity accommodating heavy protective films, mounting materials, and specialised industrial lamination applications

- Robust 4000W heating system with 160°C maximum temperature ensuring adequate thermal capacity for demanding commercial and industrial lamination requirements

- Advanced LED display control system providing precise temperature monitoring, speed adjustment, and operational status information for professional operation

- Heavy-duty 240kg construction with 800×1200×1200mm dimensions providing exceptional stability and precision for large-format professional lamination applications

- Intelligent AutoSnap technology with electro-hydraulic pressure control delivering consistent professional results for India's most demanding commercial lamination requirements

FREQUENTLY ASKED QUESTIONS

What makes the Okoboji AutoSnap 520 suitable for industrial-scale lamination operations?

The AutoSnap 520 features hydraulic pressure control, 12,000mm/min processing speeds, 200mm steel rollers, 4000W heating power, and 240kg construction designed for continuous industrial operation.

How does the hydraulic pressure system improve lamination quality compared to standard machines?

Hydraulic pressure provides superior uniform distribution, consistent force across the 480mm width, precise pressure control, and enhanced adhesive activation for professional-quality results.

What advantages do the 200mm diameter steel rollers provide for large-format lamination?

Large steel rollers offer extended contact time, superior heat retention, enhanced thermal transfer, consistent pressure application, and improved lamination quality for wide materials.

Can the AutoSnap 520 handle high-volume production requirements effectively?

Yes, with speeds up to 12,000mm/min, 4000W heating capacity, hydraulic pressure control, and robust construction, it's designed for continuous high-volume commercial production.

What types of materials and applications benefit from the 6mm film thickness capacity?

Heavy protective films, mounting materials, rigid substrates, industrial laminates, outdoor signage materials, and specialised commercial applications requiring thick film protection.

How does the LED display system enhance operational control and monitoring?

The LED display provides real-time temperature monitoring, speed control, pressure settings, operational status, and diagnostic information for precise professional operation.

Is the 240kg weight and large dimensions necessary for the AutoSnap 520's performance?

Yes, the substantial construction houses hydraulic systems, large heating elements, steel rollers, and precision components whilst providing stability for high-speed operation.

What electrical infrastructure requirements should I consider for the AutoSnap 520 installation?

The machine requires stable 220V/50Hz power with adequate capacity for 4000W heating and 400W motor power, typically requiring dedicated electrical circuits.

How does Okoboji's AutoSnap technology differ from standard thermal lamination systems?

AutoSnap technology incorporates hydraulic pressure control, intelligent automation, precision temperature management, and advanced control systems for superior professional results.

What comprehensive support services does Okoboji provide for AutoSnap industrial lamination equipment?

Okoboji offers specialised installation, operator training, preventive maintenance programs, technical support, genuine parts supply, and dedicated service for industrial lamination systems.

Customers also bought

Okoboji Corner Cutter Electric DT WH08

Okoboji Corner Cutter Manual S100

Okoboji PVC Tubebind Automatic TBA