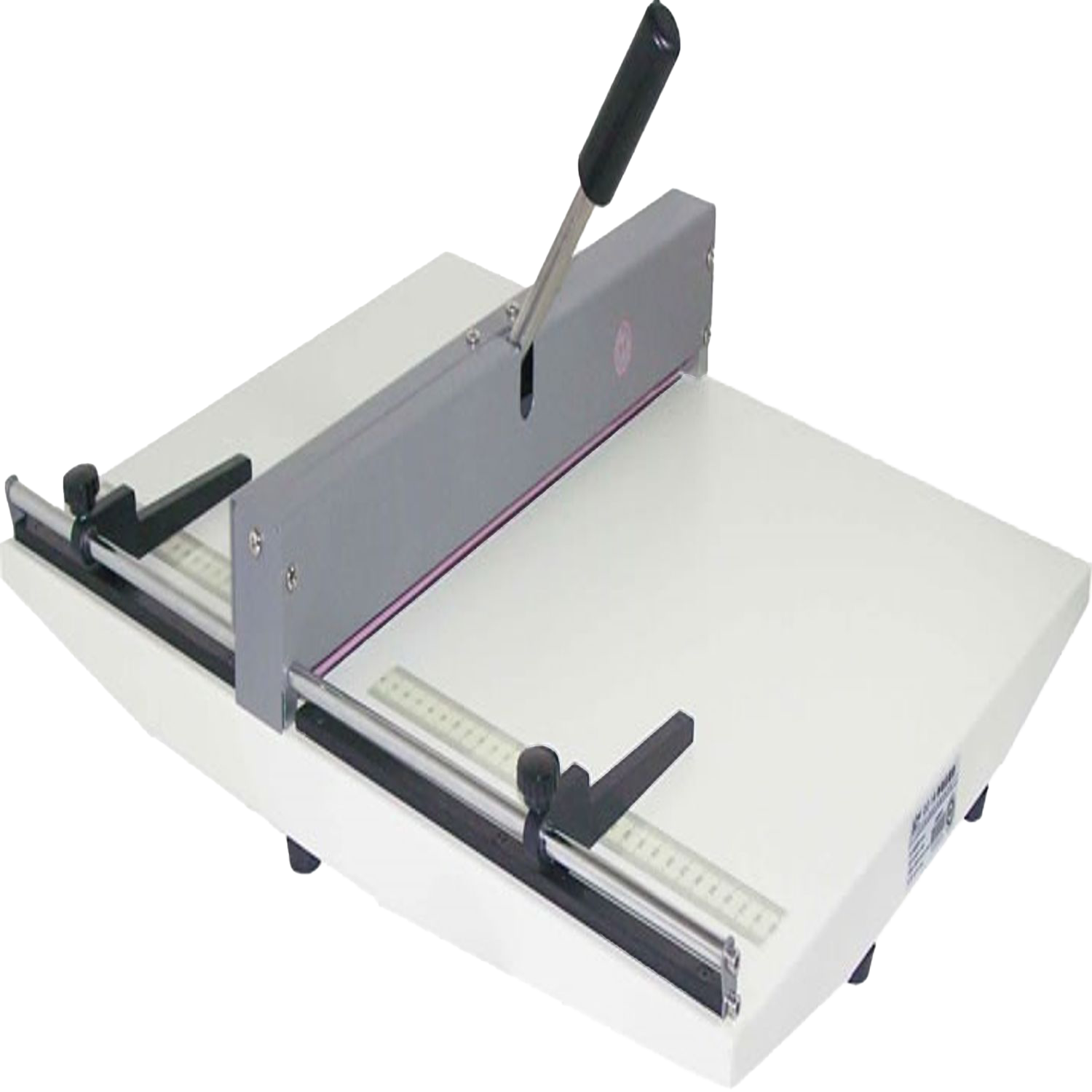

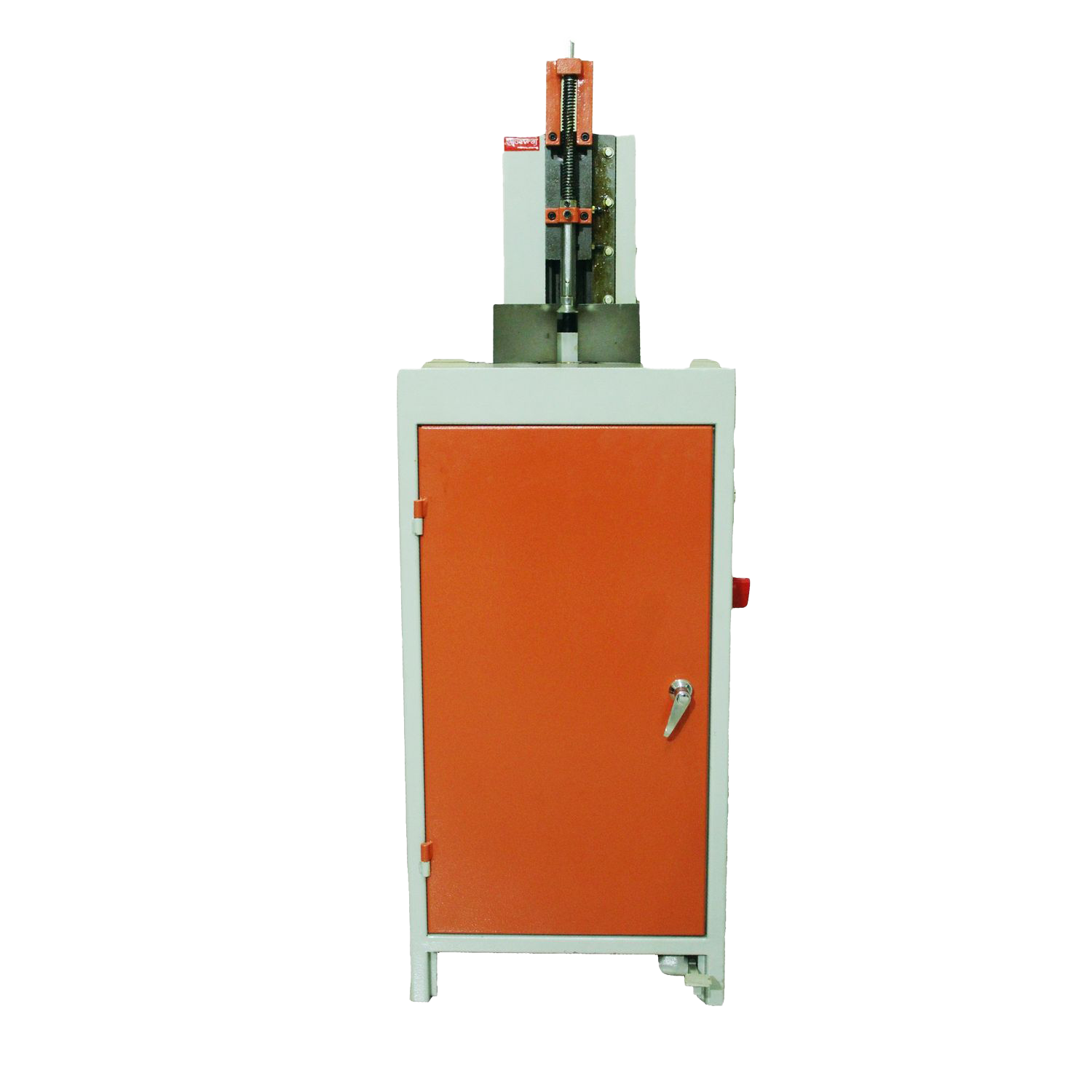

Okoboji Corner Cutter Manual Desktop M100

SPECIFICATIONS

PRODUCT VIDEO

PRODUCT DESCRIPTION

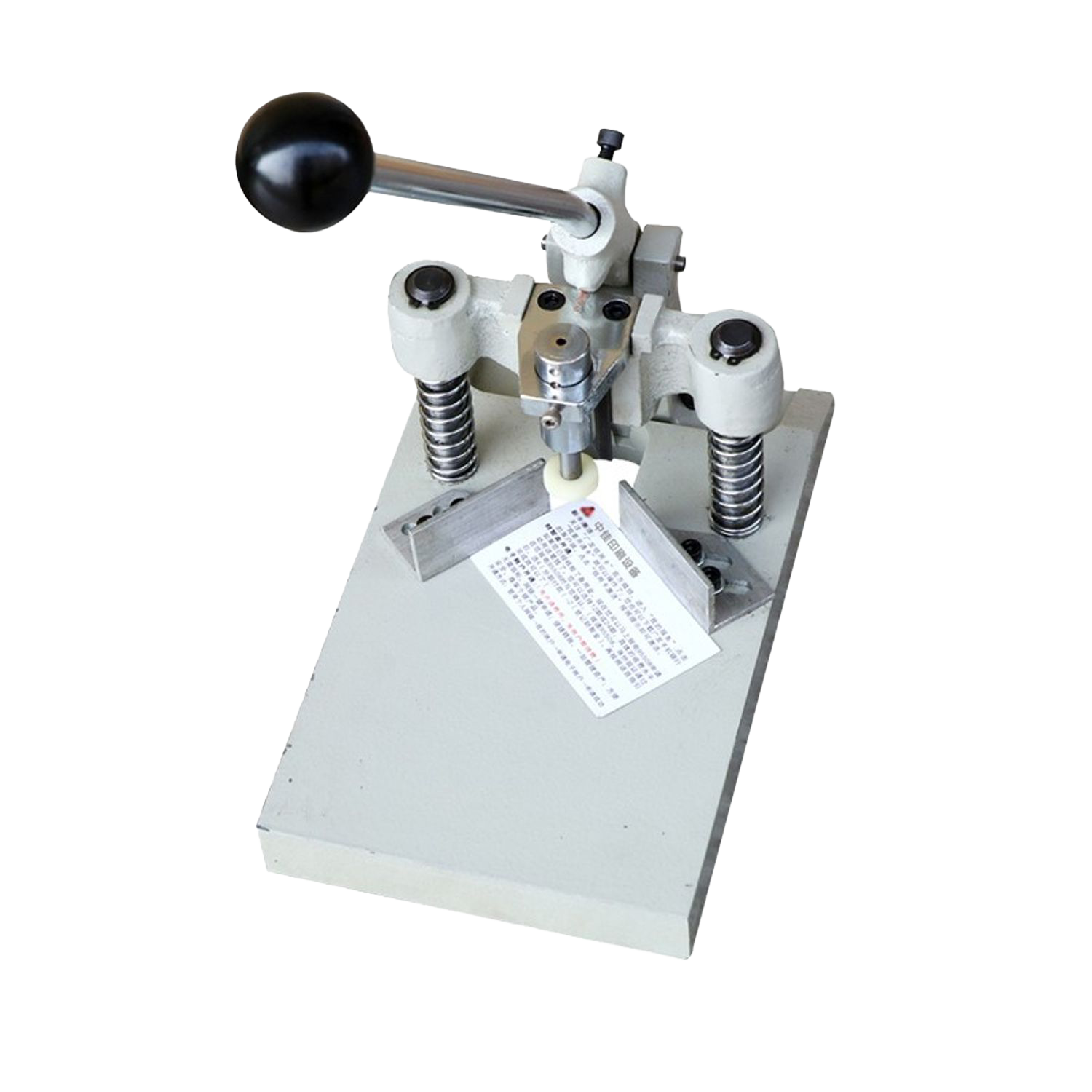

The Okoboji Corner Cutter Manual Desktop M100 delivers enhanced corner cutting capabilities through an improved manual operation system designed for demanding professional applications. This advanced manual corner cutter incorporates upgraded specifications including increased cutting thickness capacity and enhanced die configuration whilst maintaining the operational simplicity and cost-effectiveness that characterises manual corner cutting equipment. The M100 model represents a significant advancement over basic manual corner cutters, providing professional-quality results suitable for diverse commercial applications.

Featuring an enhanced cutting capacity of 3cm thickness, this desktop corner cutter accommodates thicker materials and multi-layer substrates commonly encountered in professional environments. The R6 (1/4 inch) cutting die provides optimal corner radius specifications for commercial applications whilst the comprehensive accessory package ensures accurate positioning and consistent cutting results. The upgraded M100 configuration optimises performance for businesses requiring reliable corner cutting capabilities with enhanced capacity specifications.

This professional manual corner cutter serves businesses requiring enhanced corner cutting capabilities without electrical power requirements. Applications include medium-volume printing operations, commercial document preparation, packaging operations, and professional services requiring reliable corner cutting with increased material thickness capacity compared to basic manual alternatives.

Upgrade Your Experience

Okoboji Corner Cutter Electric Heavy Duty Orange

Okoboji Corner Cutter Electric Raduis upto 20mm 5 Dye Raduis upto 20mm 5 Dye

Okoboji Corner Cutter Electric Super HD Back Motor Grey

Okoboji Corner Cutter Pneumatic Dual Head HD

KEY FEATURES

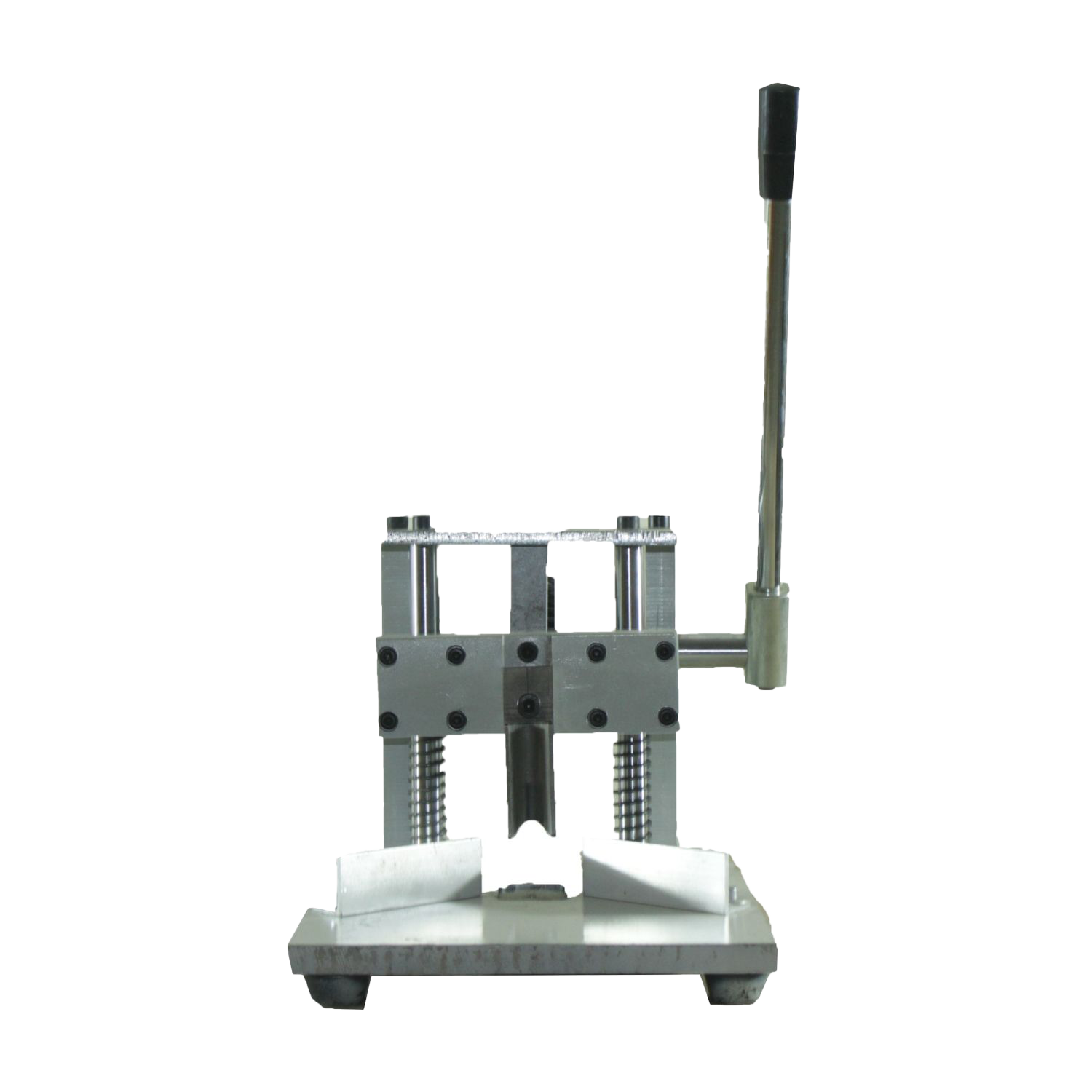

- Enhanced 3cm cutting thickness capacity accommodates thicker materials and multi-layer substrates commonly encountered in professional environments, expanding application possibilities beyond basic manual corner cutters.

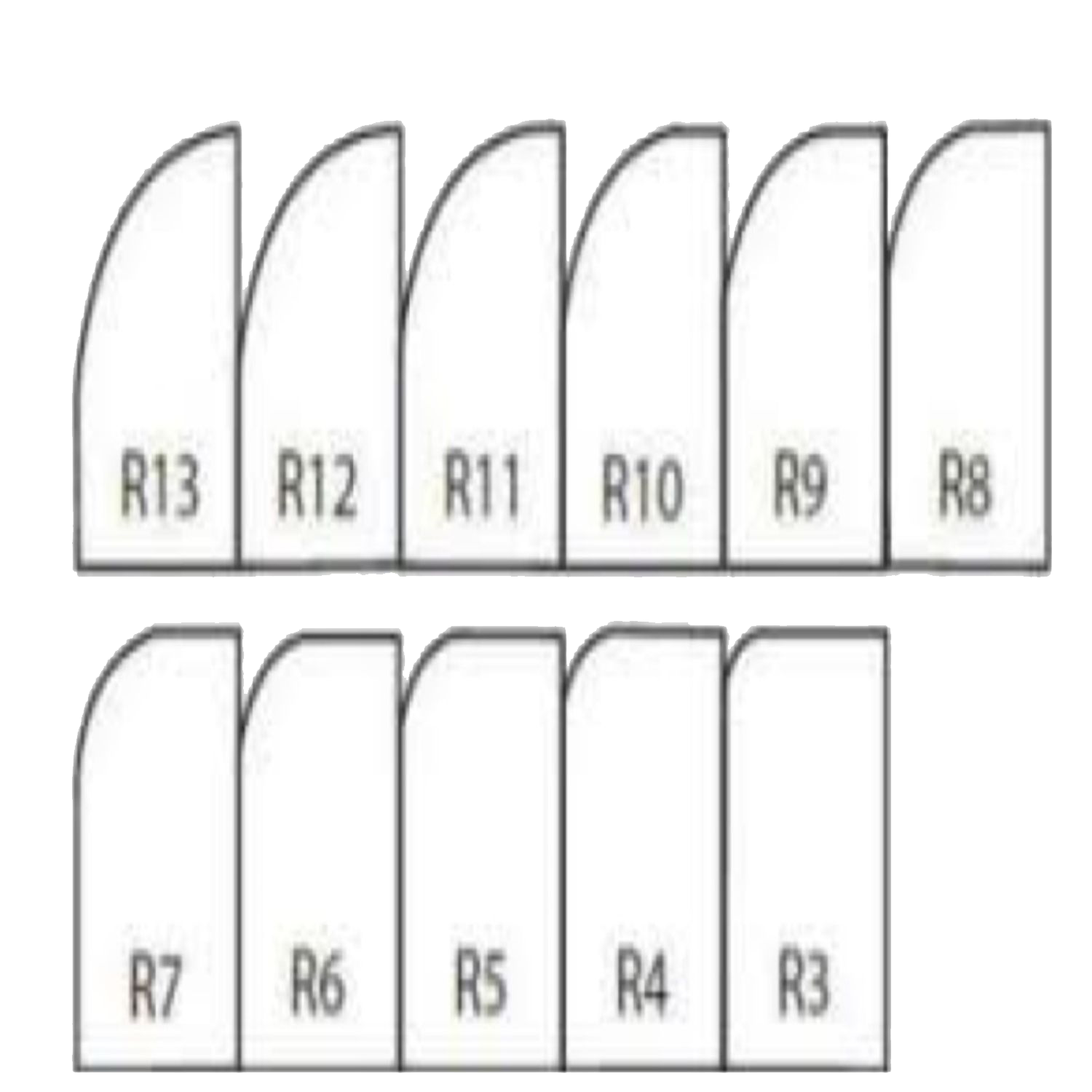

- Advanced R6 (1/4 inch) cutting die provides optimal corner radius specifications for commercial applications whilst maintaining precision cutting results suitable for professional document preparation and packaging operations.

- Comprehensive accessory package includes waste basket, L-guide system, plastic components, and radius alignment guide, ensuring complete operational capability and consistent cutting accuracy from initial installation.

- Professional desktop configuration optimises workspace efficiency whilst providing enhanced stability during operation, maintaining precision cutting results comparable to electric alternatives without power requirements.

- Multiple die compatibility accommodates 1/8, 1/4, 3/8 inch, and 45° straight cutting options, providing versatility for addressing diverse customer requirements within single Okoboji machine investment.

- Manual operation eliminates electrical power requirements whilst delivering enhanced cutting capacity, making it suitable for professional applications where electric alternatives prove impractical or unnecessary.

- Durable construction withstands demanding commercial usage whilst maintaining precision cutting capabilities throughout extended operational periods typical in professional Okoboji corner cutting applications.

- Cost-effective operation requires no electrical power, compressed air, or complex maintenance procedures whilst providing enhanced capacity specifications for professional corner cutting requirements.

FREQUENTLY ASKED QUESTIONS

How does the 3cm cutting capacity enhance operational capabilities compared to standard manual corner cutters?

The enhanced 3cm capacity enables processing of thicker materials, multi-layer substrates, and demanding applications that exceed the capabilities of basic manual corner cutters, expanding business opportunities.

What professional applications benefit from the M100's enhanced manual cutting capabilities?

Medium-volume printing operations, commercial document preparation, packaging services, and professional environments requiring reliable corner cutting with increased material thickness capacity benefit from M100 specifications.

Does the enhanced cutting capacity affect the manual operation force required?

The M100 incorporates engineered lever systems that optimise cutting force efficiency, maintaining manageable manual operation whilst accommodating increased material thickness capacity for professional applications.

What maintenance procedures ensure optimal performance for enhanced manual corner cutting equipment?

Regular cleaning of cutting mechanisms, periodic lubrication of pivot points, die inspection for sharpness, and proper accessory storage maintain optimal performance for enhanced manual corner cutting equipment.

How does the R6 cutting die serve professional corner cutting requirements?

The R6 (1/4 inch) die provides optimal corner radius specifications for commercial applications, offering professional appearance whilst maintaining compatibility with standard business document and packaging requirements.

Can the M100 handle continuous operation in professional environments effectively?

The enhanced construction and improved specifications enable reliable operation in professional environments whilst manual operation naturally regulates usage patterns suitable for sustained commercial applications.

What operator training considerations apply to enhanced manual corner cutting equipment?

Training covers proper cutting techniques for thicker materials, die selection procedures, force application methods, and safety protocols specific to enhanced capacity manual corner cutting operations.

How do the included accessories enhance accuracy for thicker material processing?

The L-guide system ensures proper alignment of thicker materials, waste basket manages increased debris, and radius alignment guide maintains positioning accuracy essential for consistent professional results.

What die options provide the greatest versatility for professional corner cutting applications?

The combination of 1/8, 1/4, and 3/8 inch dies plus 45° straight cutting option provides comprehensive coverage for most professional corner cutting requirements within commercial environments.

Does the desktop configuration provide adequate stability for enhanced cutting operations?

The engineered desktop design provides excellent stability during enhanced cutting operations whilst optimising workspace efficiency, maintaining professional accuracy comparable to larger corner cutting equipment.

Customers also bought

Okoboji Creasing and Perforation Rotary Electric A3

Okoboji Digital Foil Printer 250 X 350mm Automatic 3025XY

Okoboji Digital Foil Printer for Ribbon 150R