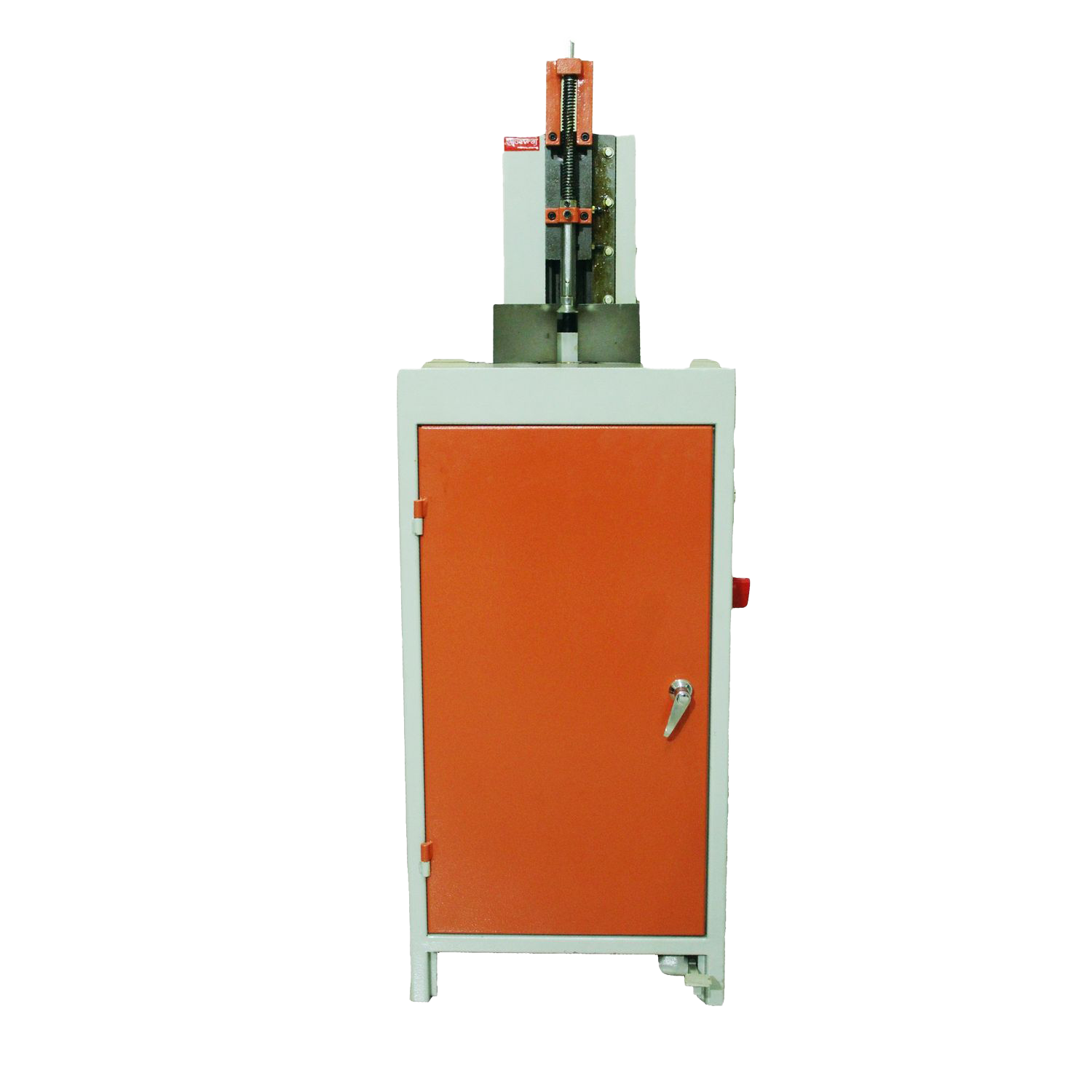

Okoboji Corner Cutter Electric Super HD Back Motor Grey

SPECIFICATIONS

PRODUCT VIDEO

PRODUCT DESCRIPTION

The Okoboji Corner Cutter Electric Super HD Back Motor Grey represents the premium tier of electric corner cutting technology, featuring an innovative rear-mounted motor configuration that optimises performance, reduces vibration, and enhances operational stability. This super heavy-duty corner cutter incorporates advanced engineering principles to deliver exceptional cutting precision and reliability in the most demanding commercial applications. The distinctive grey finish reflects the professional-grade construction and premium specifications that characterise this top-tier Okoboji model.

The revolutionary back motor design fundamentally improves the machine’s centre of gravity, reducing operational vibration and enhancing cutting precision compared to conventional front-mounted motor configurations. This engineering advancement enables more accurate corner cutting results, particularly when processing challenging materials or achieving demanding precision requirements. The super HD designation indicates enhanced construction specifications, reinforced components, and superior motor performance designed for the most intensive commercial applications.

This premium corner cutting machine serves businesses requiring the highest levels of cutting precision, operational reliability, and advanced engineering features. Industries such as high-end packaging, precision document preparation, specialised manufacturing, and premium commercial services benefit from the enhanced capabilities and superior construction quality offered by this flagship Okoboji model.

Upgrade Your Experience

Okoboji Corner Cutter Electric Heavy Duty Orange

Okoboji Corner Cutter Electric Raduis upto 20mm 5 Dye Raduis upto 20mm 5 Dye

Okoboji Corner Cutter Manual S100

Okoboji Corner Cutter Pneumatic Dual Head HD

KEY FEATURES

- Innovative back motor configuration optimises machine balance, reduces operational vibration, and enhances cutting precision compared to conventional front-mounted motor designs in professional applications.

- Super heavy-duty construction incorporates premium materials and reinforced components designed for the most demanding commercial applications requiring exceptional reliability and extended operational lifespan.

- Advanced 80mm cutting capacity handles challenging materials and thick substrates whilst maintaining precision results throughout intensive daily usage patterns typical in high-volume operations.

- Professional grey finish reflects premium construction quality whilst providing enhanced durability and professional appearance suitable for high-end commercial environments.

- Superior 180W motor delivers consistent cutting force at 1400 rpm with enhanced reliability and reduced maintenance requirements compared to standard motor configurations.

- Precision engineering ensures exceptional cutting accuracy and consistency, meeting the demanding quality standards required for premium commercial Okoboji corner cutting applications.

- Stand-alone design with optimised weight distribution provides exceptional stability during operation whilst maintaining efficient workspace utilisation for professional environments.

FREQUENTLY ASKED QUESTIONS

What advantages does the back motor configuration provide over conventional designs?

The Okoboji back motor design improves weight distribution, reduces operational vibration, enhances cutting precision, and provides better access to cutting area whilst maintaining superior stability during operation.

How does the super HD construction differ from standard heavy-duty corner cutters?

Super HD construction incorporates premium materials, reinforced components, enhanced motor specifications, and superior engineering designed for the most demanding commercial applications requiring exceptional reliability.

What specific industries benefit most from this premium corner cutting equipment?

High-end packaging, precision document preparation, specialised manufacturing, premium commercial services, and applications requiring exceptional cutting accuracy benefit from this flagship Okoboji model.

Does the grey finish provide functional benefits beyond aesthetic appeal?

The professional grey finish offers enhanced durability, reduced visible wear, improved resistance to workplace conditions, and maintains professional appearance throughout extended commercial usage.

What maintenance advantages result from the back motor configuration?

The rear-mounted motor design provides easier access for maintenance procedures, reduces exposure to cutting debris, and simplifies routine service tasks whilst maintaining optimal performance.

How does the super HD model justify its premium pricing for commercial applications?

Enhanced construction quality, superior cutting precision, reduced maintenance requirements, extended operational lifespan, and exceptional reliability provide superior long-term value for demanding applications.

What operator training considerations apply to premium corner cutting equipment?

Comprehensive training covers advanced operational techniques, precision calibration procedures, enhanced maintenance protocols, and quality control methods specific to premium Okoboji equipment.

Can this super HD corner cutter handle continuous operation in high-volume environments?

Yes, the super heavy-duty construction and enhanced motor specifications enable reliable continuous operation suitable for high-volume commercial environments requiring consistent performance.

What technical support is available for premium corner cutting equipment?

Okoboji provides priority technical support including expedited service response, comprehensive maintenance guidance, and specialised assistance for premium equipment installations.

How does the back motor design affect workspace requirements and installation?

The optimised design maintains compact footprint whilst improving stability and accessibility, requiring standard workspace allocation whilst providing enhanced operational benefits for professional environments.

Customers also bought

Okoboji Digital Foil Printer 350mm High Speed 360C

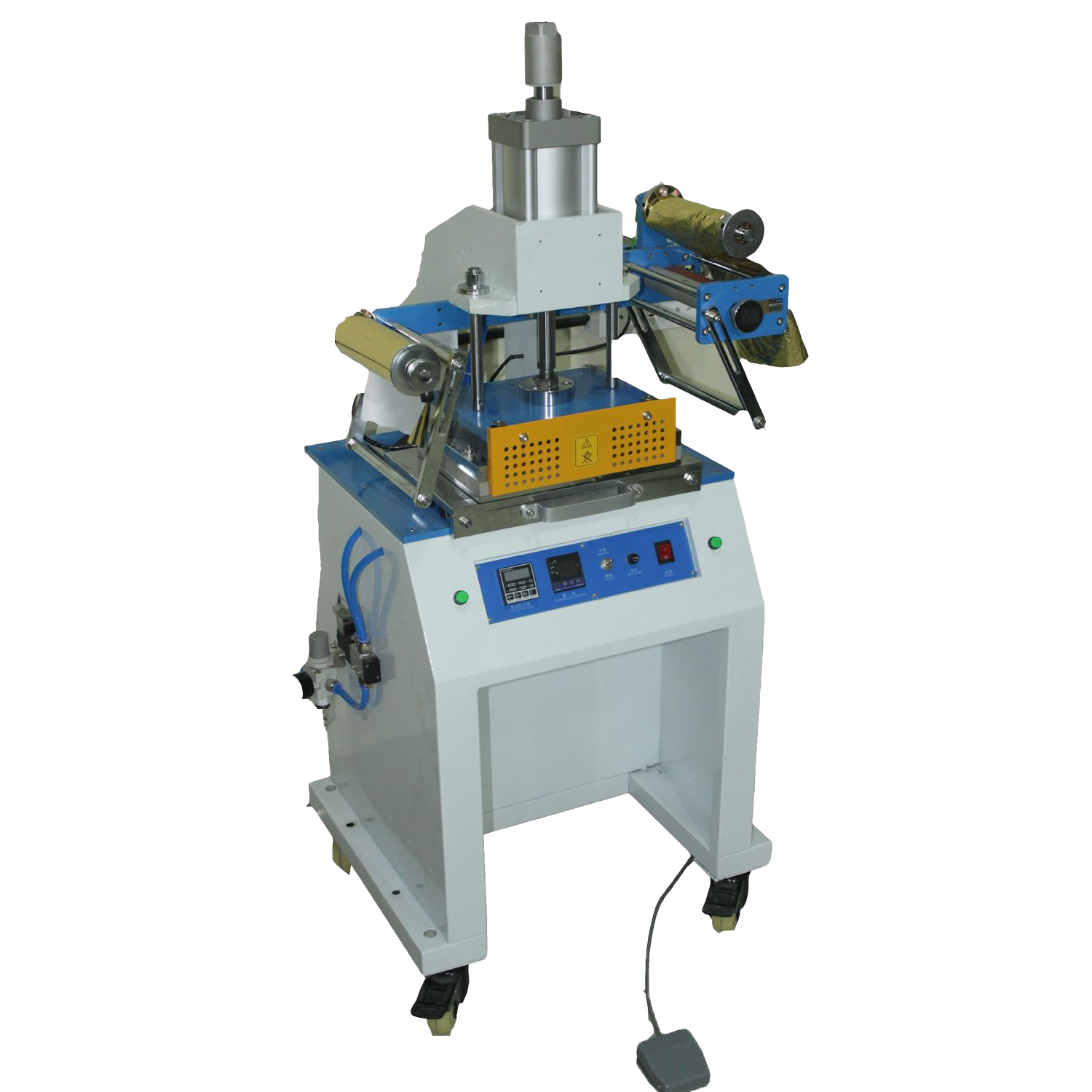

Okoboji Hot Stamping 9" X 12" FSA4

Okoboji Paper Creaser Automatic W auto pickup K330C