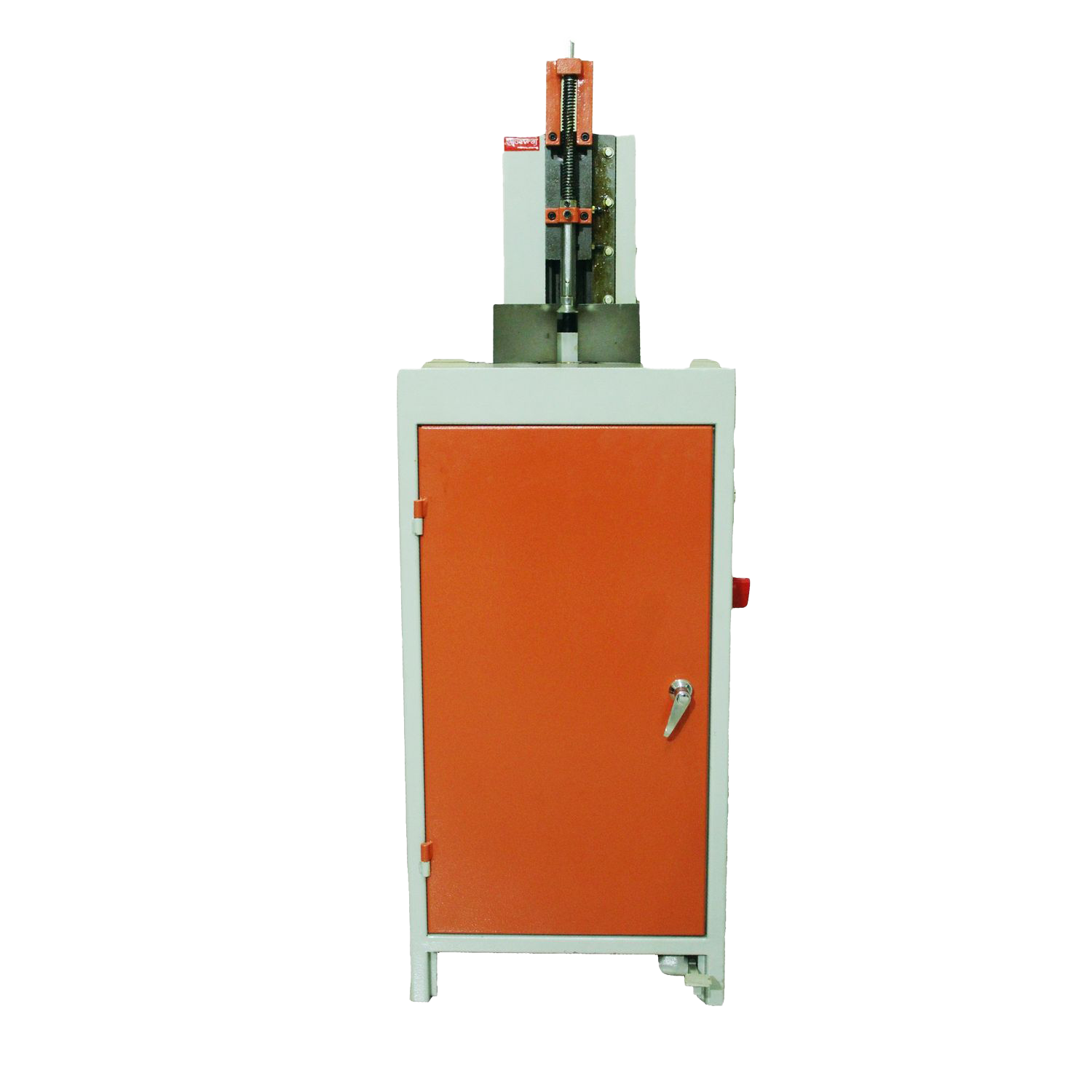

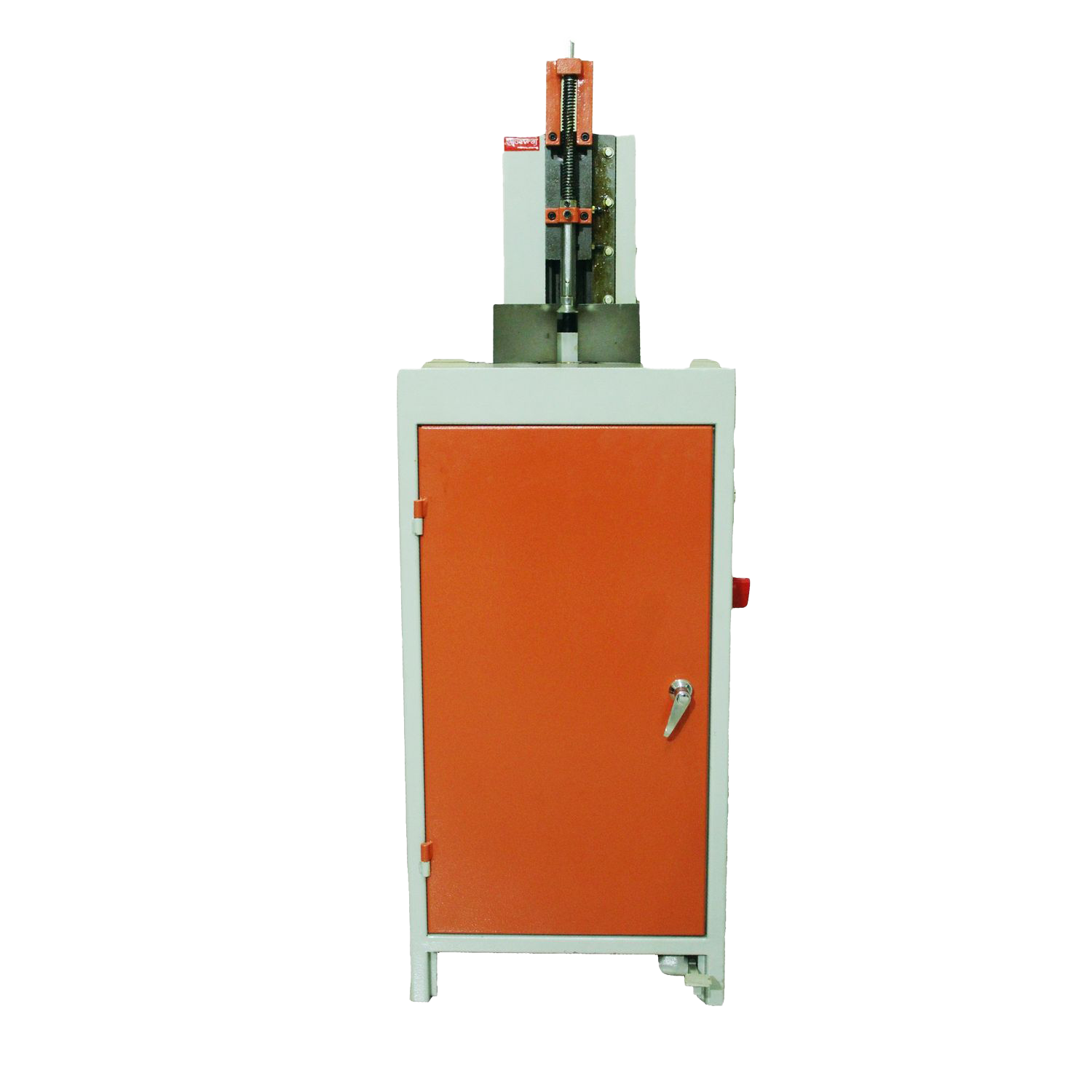

Okoboji Corner Cutter Electric Heavy Duty Orange

SPECIFICATIONS

PRODUCT VIDEO

PRODUCT DESCRIPTION

The Okoboji Electric Heavy Duty Corner Cutter in vibrant orange represents the pinnacle of industrial corner cutting technology designed for demanding commercial environments. This stand-alone heavy-duty machine combines robust construction with exceptional cutting capabilities, processing materials up to 80mm thickness with remarkable precision and speed. The distinctive orange colour coding makes it easily identifiable in busy workshop environments whilst reflecting its heavy-duty industrial heritage and robust performance characteristics.

Engineered specifically for high-volume operations, this electric corner cutter features an R8-R12 five-knife system that provides optimal radius options for business cards, industrial documents, and commercial materials. The powerful 180W motor delivers consistent performance at 1400 rpm, maintaining an efficient working rate of 56 cuts per minute even under continuous operation. Okoboji’s commitment to industrial-grade quality ensures this heavy-duty corner cutter withstands the rigorous demands of manufacturing environments, printing facilities, and commercial operations throughout India.

Upgrade Your Experience

Okoboji Corner Cutter Electric Raduis upto 20mm 5 Dye Raduis upto 20mm 5 Dye

Okoboji Corner Cutter Electric Super HD Back Motor Grey

Okoboji Corner Cutter Manual Desktop M100

Okoboji Manual Hand Held Corner Cutter

KEY FEATURES

- Heavy-duty industrial construction designed specifically for demanding commercial environments and continuous high-volume corner cutting operations.

- Stand-alone operation capability provides flexibility in workshop placement and integration with existing production workflows and machinery setups.

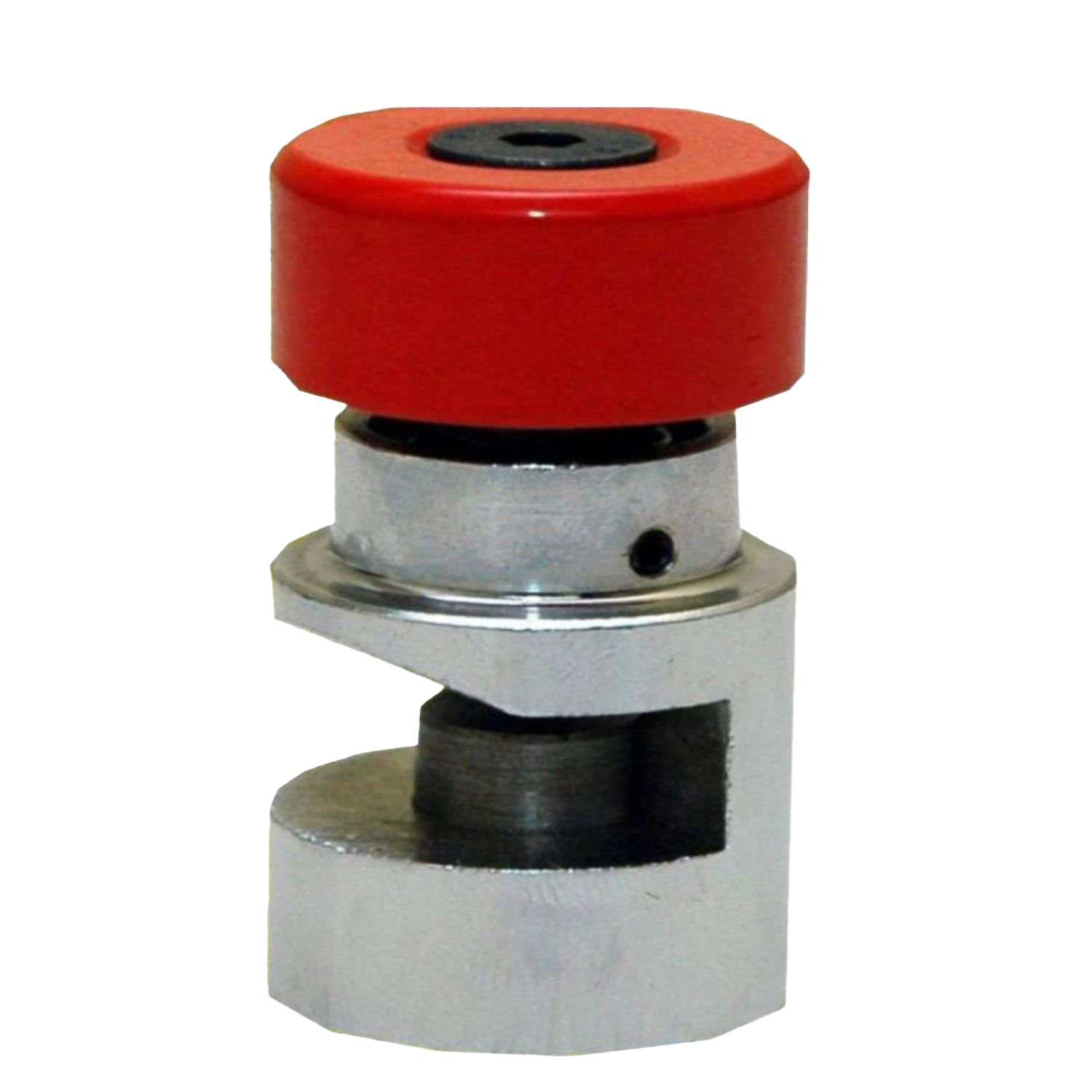

- R8-R12 five-knife radius system optimised for industrial applications requiring larger corner radius specifications and professional finish quality.

- Robust 180W motor with 1400 rpm operation ensures reliable performance under heavy workloads and sustained commercial usage patterns.

- 80mm maximum cutting thickness accommodates substantial material stacks and thick industrial documents requiring professional corner finishing.

- Distinctive orange colour coding enhances workshop visibility and safety compliance whilst reflecting the machine's heavy-duty industrial classification.

- Consistent 56 cuts per minute working rate maintains productivity levels essential for commercial operations and manufacturing deadlines.

- Okoboji's proven reliability and engineering excellence ensures minimal downtime and maximum return on investment for business operations.

FREQUENTLY ASKED QUESTIONS

What makes this Okoboji corner cutter specifically heavy-duty compared to standard models?

The heavy-duty designation reflects its robust construction, enhanced motor capabilities, and engineering designed for continuous commercial operation under demanding industrial conditions and high-volume processing requirements.

Why is the R8-R12 knife system particularly suitable for industrial applications?

The R8-R12 range provides larger radius options ideal for industrial documents, commercial materials, and applications requiring substantial corner rounding that enhances durability and professional appearance.

How does the stand-alone design benefit commercial operations?

Stand-alone operation provides placement flexibility, eliminates dependency on other equipment, simplifies maintenance access, and allows integration into existing production workflows without workspace constraints.

What is the significance of the orange colour in industrial equipment?

The orange colour coding follows industrial standards for visibility and safety identification, making the machine easily recognizable in busy workshops whilst indicating its heavy-duty classification and operational status.

Can this heavy-duty corner cutter handle continuous 8-hour operation cycles?

Yes, the robust 180W motor and heavy-duty construction are specifically engineered for sustained commercial operation, including full-day production cycles in industrial and manufacturing environments.

What materials work best with the R8-R12 knife configuration?

This knife system efficiently processes thick cardstock, industrial documents, laminated materials, heavy paper stocks, and commercial printing materials requiring larger radius corner cuts.

How does Okoboji ensure reliability in heavy-duty industrial applications?

Okoboji employs rigorous quality control, industrial-grade components, comprehensive testing, and proven engineering practices to deliver machines that withstand demanding commercial use throughout India.

What power infrastructure is required for this heavy-duty electric corner cutter?

The machine operates on standard commercial electrical supply with its 180W motor, making it compatible with most industrial facilities without requiring specialized power installations or modifications.

How does the 56 cuts per minute rate impact commercial productivity?

This processing speed significantly reduces labour costs, eliminates bottlenecks in production workflows, and ensures efficient material processing that meets commercial deadlines and volume requirements.

What support does Okoboji provide for industrial customers using this equipment?

Okoboji offers comprehensive technical support, industrial maintenance programs, genuine spare parts availability, and customer service designed specifically for commercial and industrial equipment users.

Customers also bought

Okoboji Digital Foil Printer 250 X 350mm Automatic 3025XY

Okoboji Digital Foil Printer 57 X 250mm X axis 8025

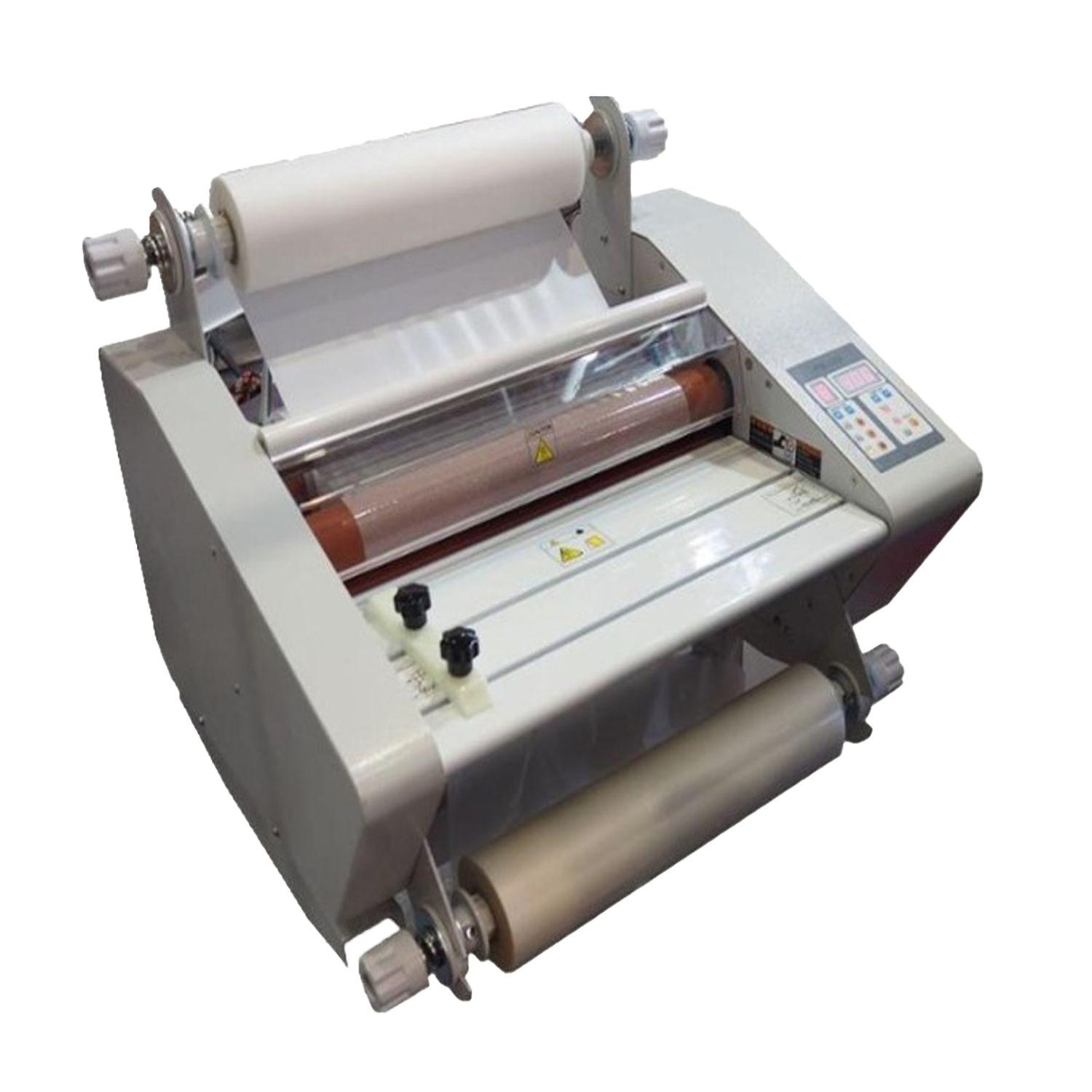

Okoboji Thermal Roll Laminator 3816