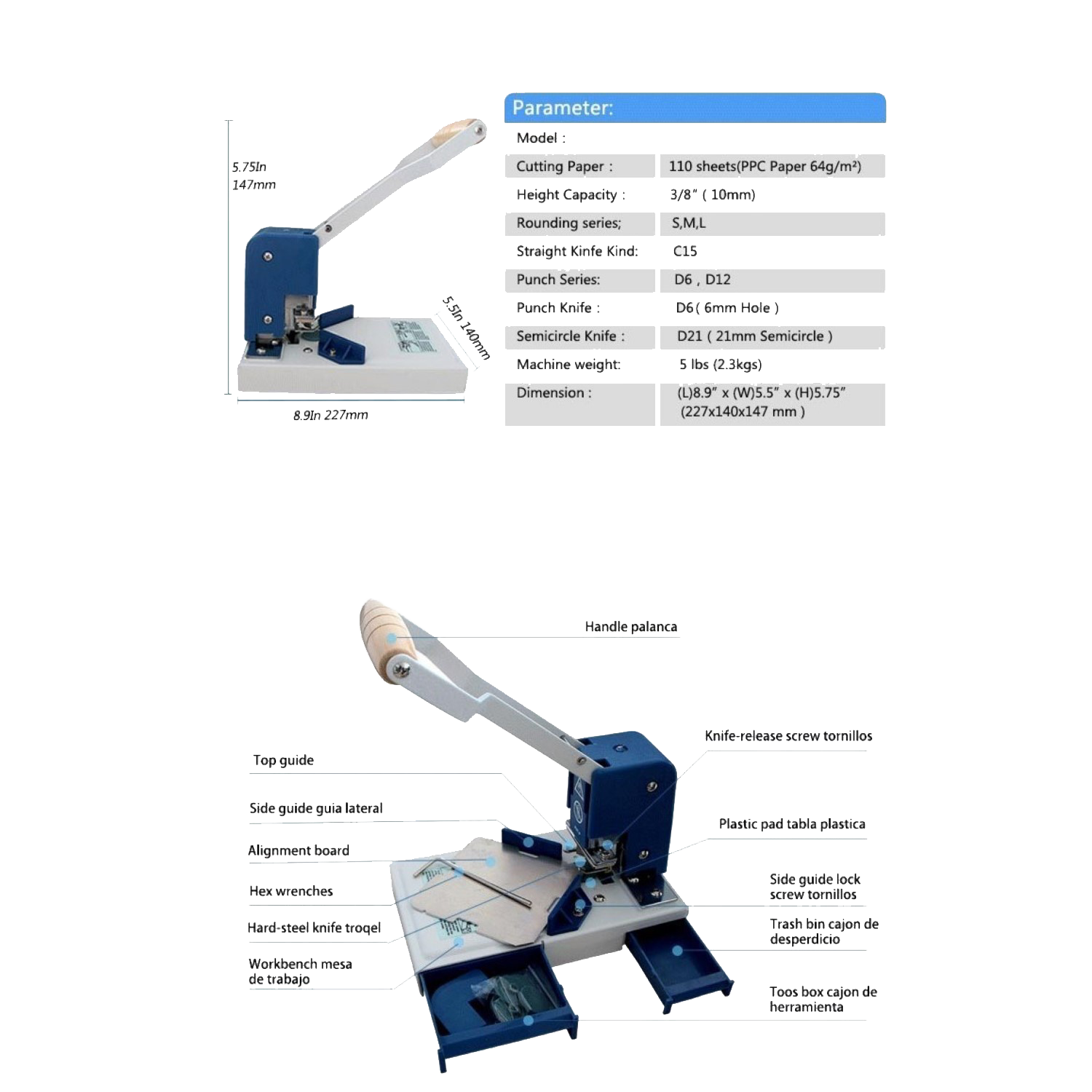

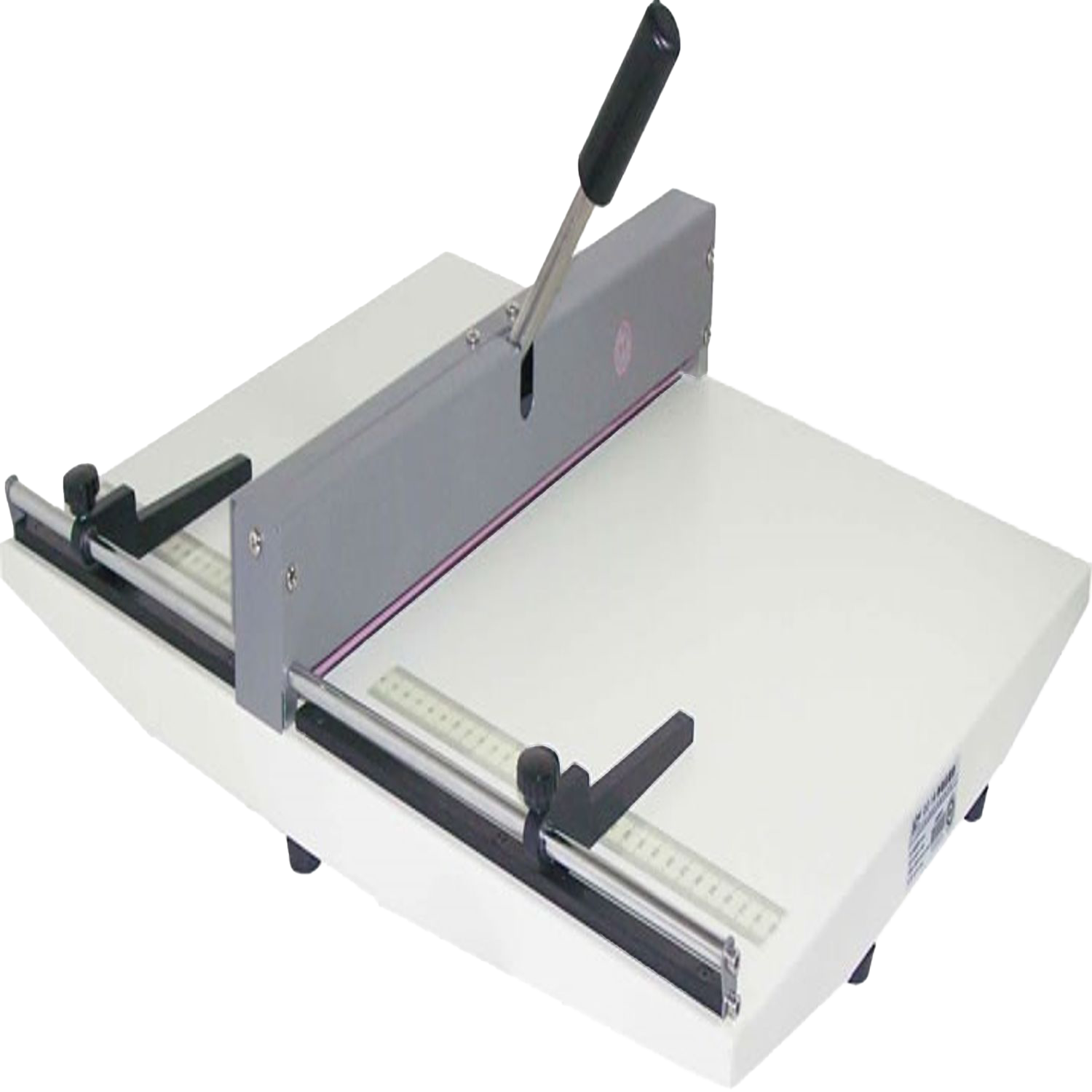

Okoboji Corner Cutter Manual S100

SPECIFICATIONS

PRODUCT VIDEO

PRODUCT DESCRIPTION

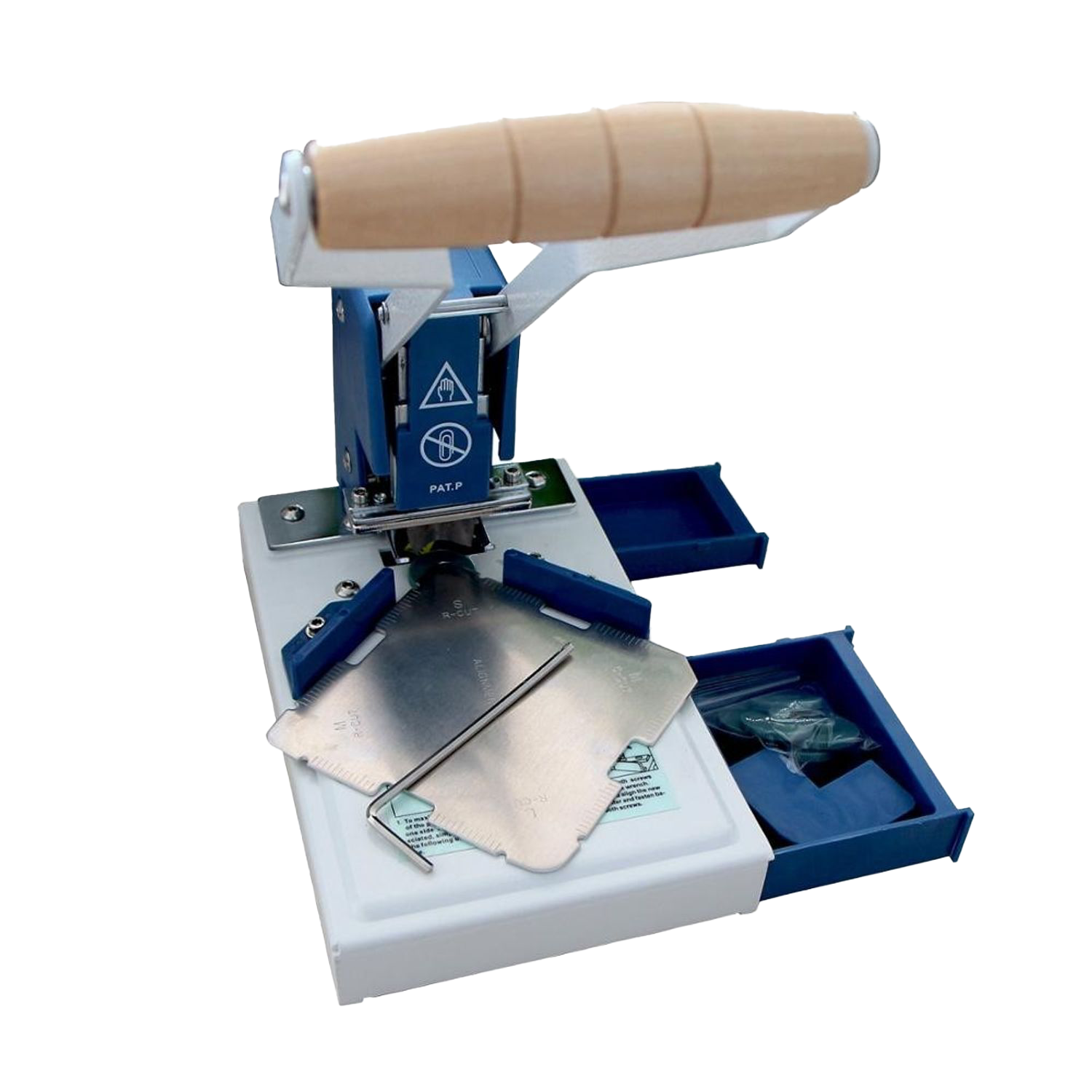

The Okoboji Corner Cutter Manual S100 represents an exceptional solution for businesses requiring precise corner cutting capabilities without the complexity and power requirements of electric alternatives. This compact manual corner cutter delivers professional-quality results through carefully engineered mechanical systems that provide consistent cutting force and accuracy across diverse applications. The S100 model serves as an ideal entry point for businesses beginning corner cutting operations or as a reliable backup system for established operations requiring portable cutting capabilities.

Designed with user-friendly operation principles, this manual corner cutter incorporates comprehensive accessories including waste basket, L-guide system, plastic parts, and radius alignment guide to ensure accurate positioning and clean cutting results. The included die selection provides immediate operational capability whilst the compact desktop configuration optimises workspace efficiency in environments where space constraints or power limitations make electric alternatives impractical.

This versatile Okoboji corner cutter serves diverse business applications including small printing operations, office environments, educational institutions, and craft businesses requiring reliable corner cutting capabilities. The manual operation eliminates electrical requirements whilst maintaining professional-quality results, making it particularly suitable for mobile applications, temporary setups, and environments where electrical corner cutters prove impractical.

Upgrade Your Experience

Okoboji Corner Cutter Electric Heavy Duty Orange

Okoboji Corner Cutter Electric Raduis upto 20mm 5 Dye Raduis upto 20mm 5 Dye

Okoboji Corner Cutter Electric Super HD Back Motor Grey

Okoboji Corner Cutter Pneumatic Dual Head HD

KEY FEATURES

- Compact desktop configuration optimises workspace utilisation whilst providing stable operation platform for accurate corner cutting results in space-constrained professional environments.

- Comprehensive accessory package includes waste basket, L-guide system, plastic components, and radius alignment guide, providing complete operational capability from initial installation.

- Multiple die options including 1/8, 1/4, and 3/8 inch sizes accommodate diverse corner cutting requirements, enabling operators to address varied customer specifications within single Okoboji machine investment.

- Manual operation eliminates electrical power requirements, reducing operational costs and enabling use in mobile applications, temporary setups, and locations without convenient electrical access.

- Professional 0.4 capacity specification handles standard commercial materials whilst maintaining precision cutting results suitable for business cards, documents, and lightweight packaging applications.

- Included L-guide system ensures accurate material positioning and consistent cutting results, reducing operator error and improving overall productivity in professional Okoboji corner cutting operations.

- Durable construction withstands regular commercial usage whilst maintaining precision cutting capabilities throughout extended operational periods typical in business environments.

- Cost-effective operation requires no electrical power, compressed air, or complex maintenance procedures, providing economical corner cutting solution for budget-conscious businesses.

FREQUENTLY ASKED QUESTIONS

What material types work best with the manual S100 corner cutter?

The Okoboji S100 effectively processes paper stocks, lightweight cardboard, business cards, laminated materials, and thin plastic sheets up to 0.4 inch capacity, making it ideal for office and light commercial applications.

How does manual operation compare to electric corner cutters for small businesses?

Manual operation provides cost-effective corner cutting without electrical requirements, making it suitable for small businesses, mobile applications, and environments where electric alternatives prove impractical or unnecessary.

What maintenance procedures ensure optimal performance for manual corner cutting equipment?

Regular cleaning of cutting area, periodic lubrication of pivot points, die inspection for sharpness, and proper storage of accessories maintain optimal performance for manual Okoboji corner cutting equipment.

Can the S100 handle high-volume corner cutting requirements effectively?

The S100 serves moderate-volume applications efficiently, though businesses requiring high-volume processing may benefit from electric alternatives whilst maintaining the S100 as backup or specialised equipment.

What operator training is required for manual corner cutting equipment?

Basic training covers proper material positioning, die selection, cutting technique, and safety procedures, typically requiring minimal time for competent operation of manual corner cutting equipment.

How do the included accessories enhance corner cutting accuracy and efficiency?

The L-guide ensures proper material alignment, waste basket collects debris, plastic parts protect cutting surfaces, and radius alignment guide improves positioning accuracy for consistent professional results.

What die sizes are immediately available, and can additional sizes be obtained?

The S100 includes 1/8 and 1/4 inch dies immediately, with 3/8 inch and 45° straight cutting options available, whilst additional die sizes can be obtained through Okoboji service centres.

Does the compact desktop configuration affect cutting stability or accuracy?

The engineered desktop design provides excellent stability during operation whilst optimising workspace efficiency, maintaining professional cutting accuracy comparable to larger corner cutting equipment.

What applications benefit most from manual corner cutting capabilities?

Office document preparation, small printing operations, craft businesses, educational institutions, and mobile services benefit from the flexibility and cost-effectiveness of manual Okoboji corner cutting equipment.

How does the S100 serve as backup equipment for electric corner cutting operations?

The manual S100 provides reliable backup capability during electric equipment maintenance, power outages, or mobile applications whilst maintaining compatible cutting quality for business continuity.

Customers also bought

Okoboji Creasing Machine Automatic 12.5" ACM12

Okoboji Paper Creaser Manual A3 Size H460

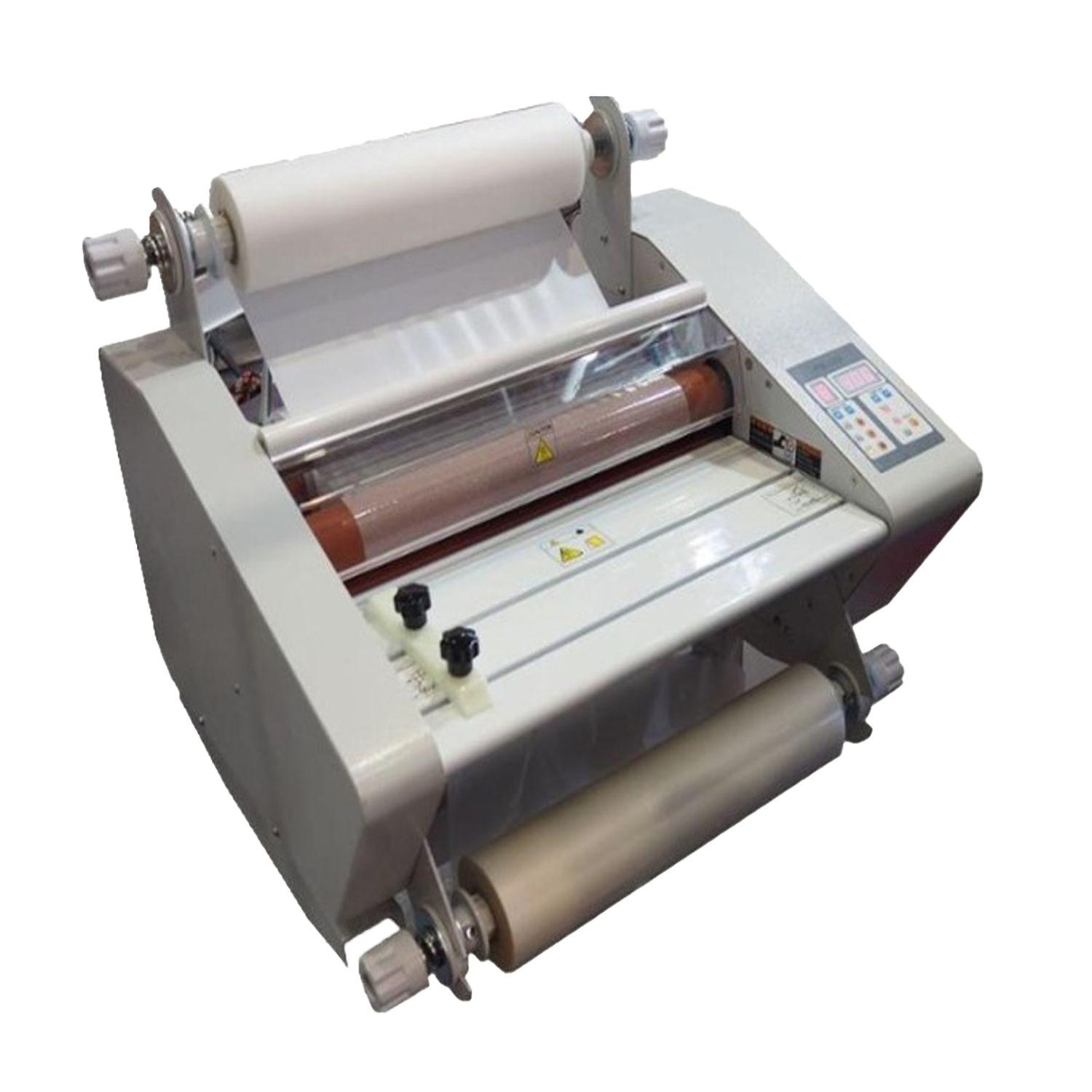

Okoboji Thermal Roll Laminator 358