Okoboji Corner Cutter Electric Raduis upto 20mm 5 Dye Raduis upto 20mm 5 Dye

SPECIFICATIONS

PRODUCT VIDEO

PRODUCT DESCRIPTION

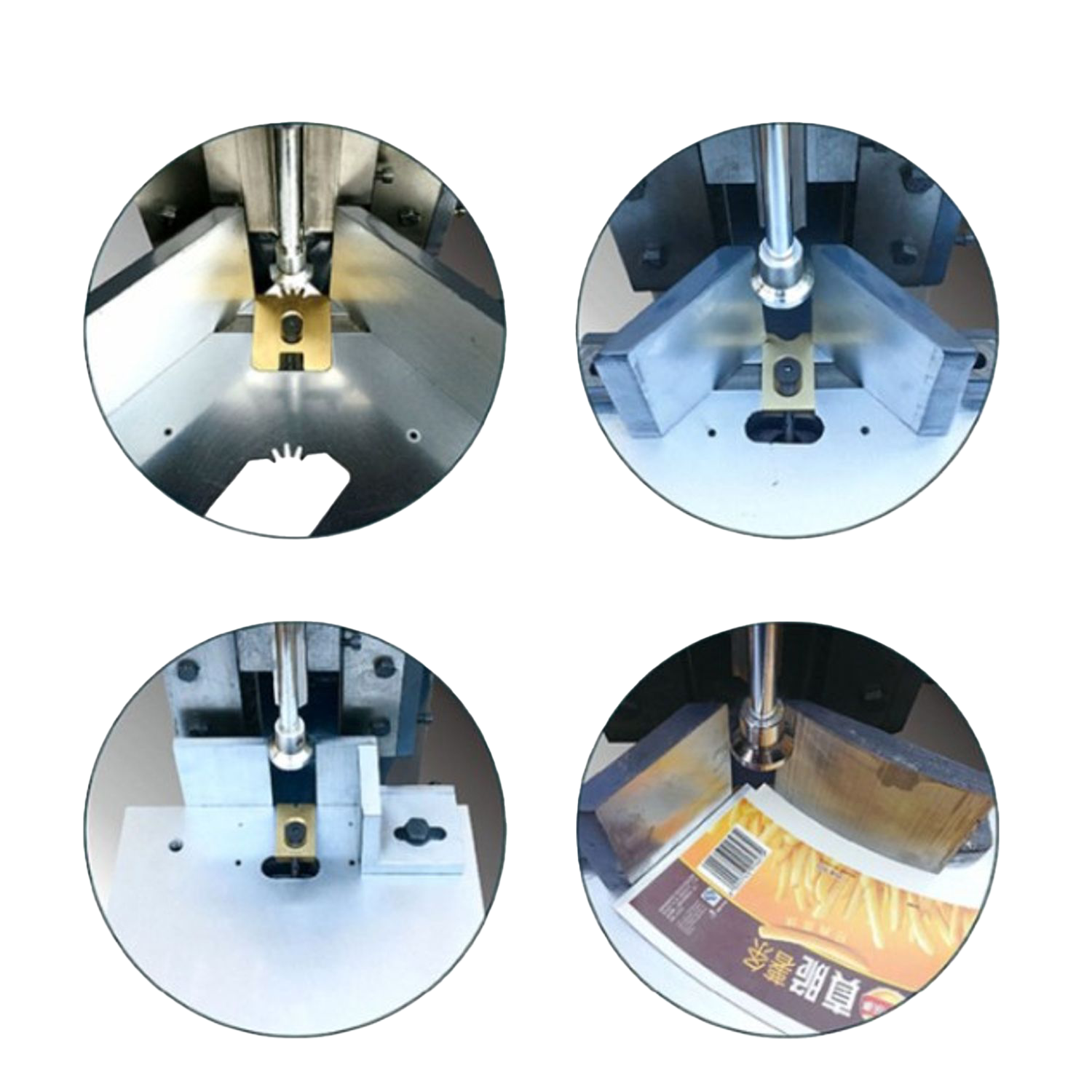

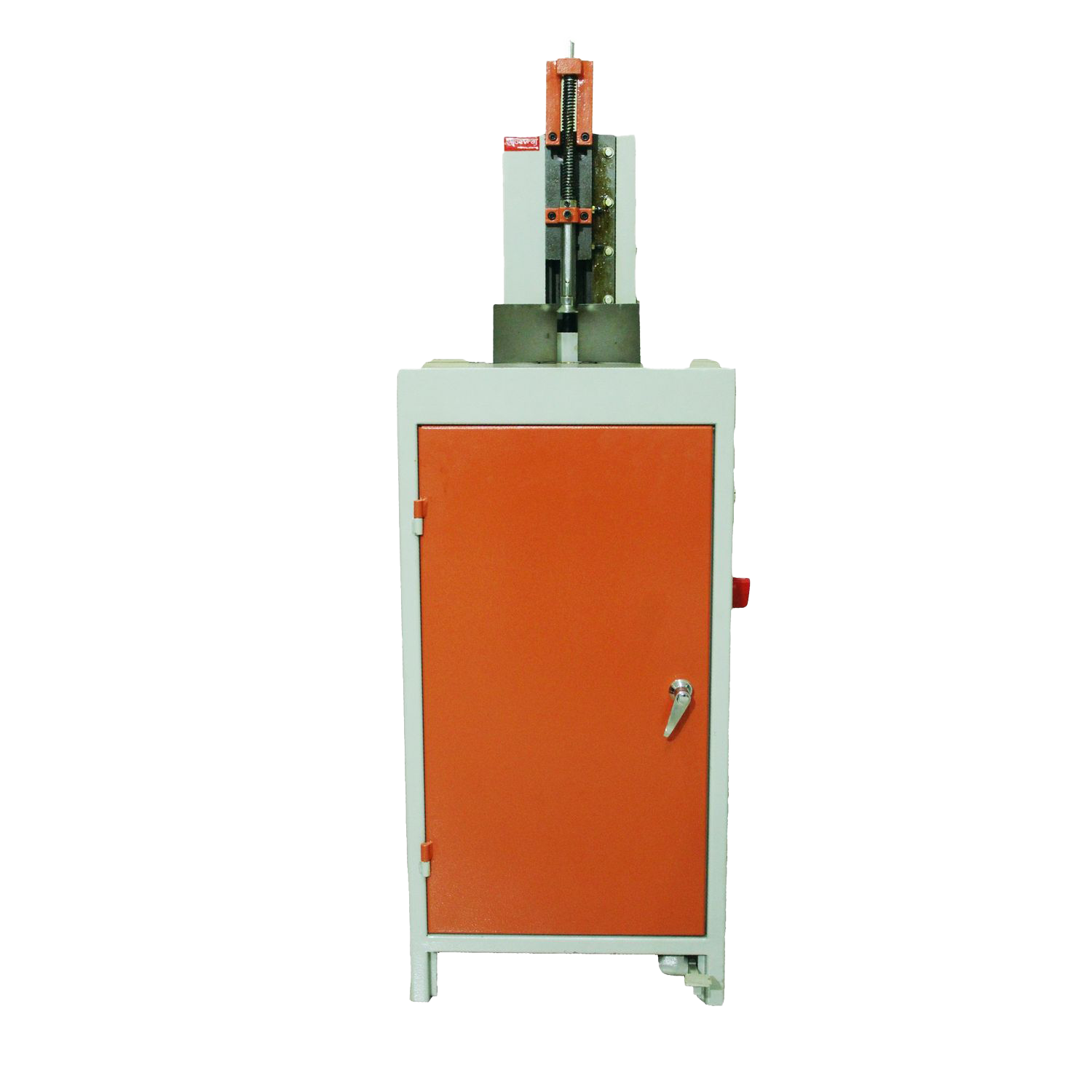

The Okoboji Corner Cutter Electric Radius up to 20mm 5 Die represents an advanced corner cutting solution specifically engineered for applications requiring larger corner radius specifications and enhanced versatility in professional cutting operations. This sophisticated electric corner cutter extends the boundaries of conventional corner cutting capabilities by accommodating radius specifications up to 20mm, making it invaluable for specialised applications in packaging, display materials, and custom document preparation where standard corner cutting equipment proves insufficient.

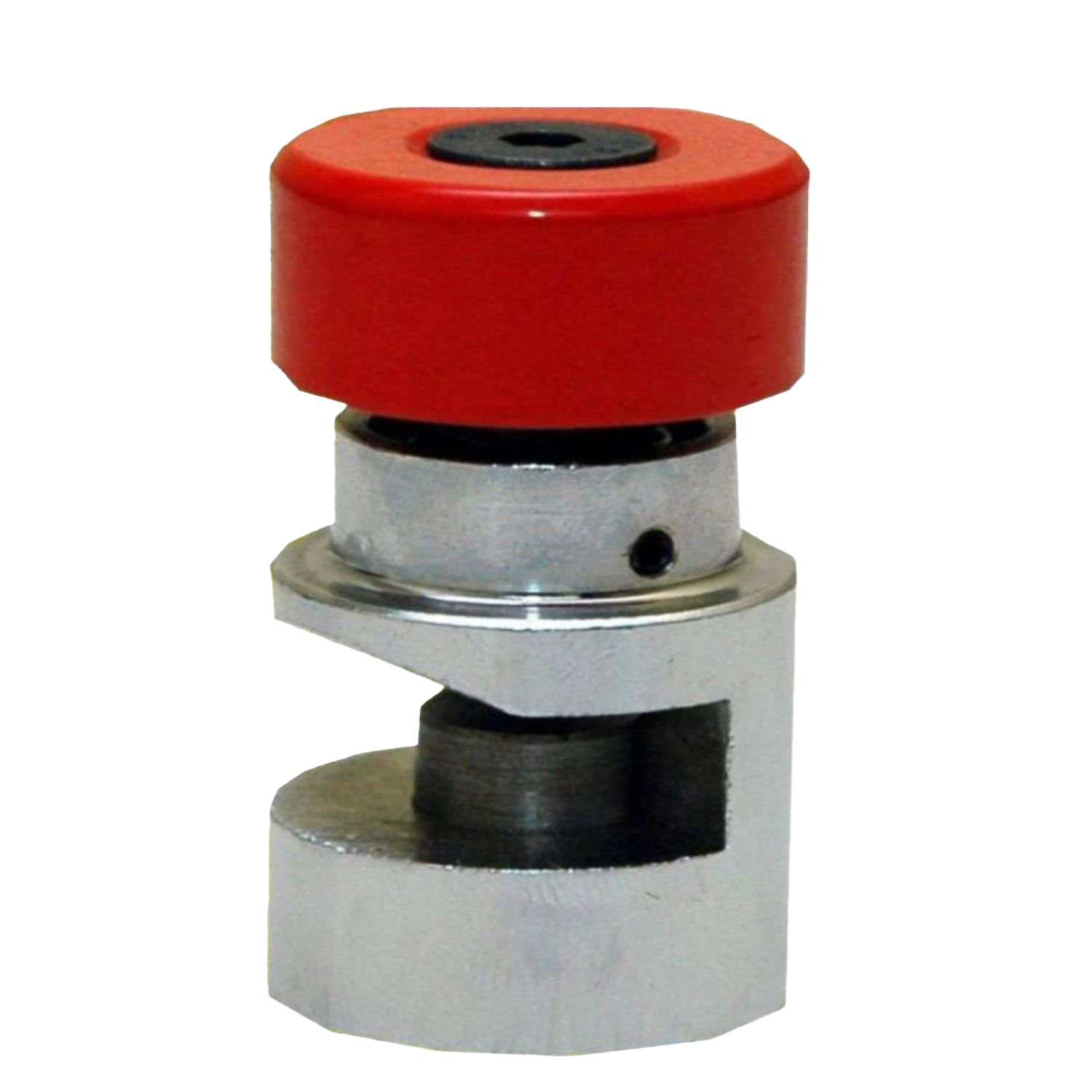

The comprehensive five-die system incorporated within this corner cutting machine provides operators with extensive flexibility for addressing diverse customer requirements and project specifications. This enhanced die configuration enables businesses to tackle a broader range of corner cutting applications whilst maintaining the precision and consistency that characterises professional Okoboji equipment. The ability to achieve larger radius corners opens new possibilities for creative packaging design, premium document finishing, and specialised commercial applications.

This advanced corner cutter serves businesses requiring specialised corner cutting capabilities that extend beyond standard commercial applications. Industries such as high-end packaging, display material preparation, architectural drafting, and custom document services benefit significantly from the expanded radius capabilities and comprehensive die selection offered by this Okoboji model.

Upgrade Your Experience

Okoboji Corner Cutter Electric Heavy Duty Orange

Okoboji Corner Cutter Electric Super HD Back Motor Grey

Okoboji Corner Cutter Manual Desktop M100

Okoboji Manual Hand Held Corner Cutter

KEY FEATURES

- Extended radius capability up to 20mm enables specialised corner cutting applications not achievable with standard equipment, opening new possibilities for creative packaging and premium document finishing.

- Comprehensive five-die system provides exceptional versatility for addressing diverse customer requirements, enabling operators to tackle varied projects within a single Okoboji machine investment.

- Professional 80mm cutting capacity accommodates thick materials and multi-layer substrates commonly encountered in high-end packaging and specialised commercial applications.

- Advanced R8-R12 knife configuration optimises performance for larger radius cutting operations whilst maintaining precision results across diverse material types and thicknesses.

- Reliable 180W motor delivers consistent cutting force at 1400 rpm, ensuring dependable operation even when processing challenging materials or achieving demanding radius specifications.

- Rapid processing speed of 56 cuts per minute maintains productivity levels whilst accommodating the enhanced complexity of larger radius corner cutting operations.

- Precision engineering ensures accurate radius specifications consistently across all cutting operations, meeting demanding quality standards for professional Okoboji corner cutting applications.

- Versatile material compatibility enables processing of diverse substrates including thick cardboard, specialty papers, laminated materials, and custom packaging components requiring precise corner finishing.

FREQUENTLY ASKED QUESTIONS

What specific applications benefit from the 20mm radius corner cutting capability?

High-end packaging, display materials, architectural drawings, premium document finishing, custom folders, and specialised commercial applications requiring larger corner radius specifications benefit from this enhanced Okoboji capability.

How does the five-die system enhance operational versatility compared to standard corner cutters?

The comprehensive die selection enables operators to address diverse customer requirements, tackle varied project specifications, and accommodate different radius needs within a single machine investment, improving business flexibility.

What materials perform best with larger radius corner cutting operations?

Thick cardboard, specialty papers, laminated materials, plastic sheets, and custom packaging components respond excellently to larger radius cutting, providing smooth, professional-quality corner finishing results.

Can this corner cutter maintain precision when processing maximum 80mm thickness materials?

Yes, the robust motor specifications and precision engineering ensure consistent accuracy even when processing maximum thickness materials, maintaining professional quality standards throughout demanding applications.

What training considerations apply to operating advanced radius corner cutting equipment?

Operator training covers die selection procedures, radius specification guidelines, material positioning techniques, and quality control methods specific to larger radius cutting operations requiring enhanced precision.

How does the 20mm radius capability compare to standard corner cutting equipment limitations?

Standard corner cutters typically accommodate radius specifications up to 10-12mm, while this Okoboji model extends capabilities to 20mm, effectively doubling the range of achievable corner finishing options.

What maintenance procedures ensure optimal performance for advanced corner cutting operations?

Regular die inspection, precision calibration checks, motor maintenance, lubrication of moving parts, and cleaning procedures maintain peak performance for demanding radius cutting applications.

Does the enhanced radius capability affect cutting speed or productivity levels?

The 56 cuts per minute speed maintains efficient productivity whilst accommodating the enhanced complexity of larger radius operations, ensuring cost-effective operation for specialised applications.

What quality control measures help maintain consistent radius specifications?

Regular calibration checks, die condition monitoring, test cutting procedures, and dimensional verification ensure consistent radius accuracy meeting professional Okoboji quality standards.

How does this advanced model justify its investment for specialised corner cutting applications?

The unique 20mm radius capability enables businesses to tackle specialised projects, serve demanding customers, and differentiate services whilst maintaining the reliability and precision expected from Okoboji equipment.

Customers also bought

Okoboji Digital Foil Printer 250 X 350mm Automatic 3025XY

Okoboji Digital Foil Printer 57 X 250mm X axis 8025

Okoboji Thermal Roll Laminator 3816